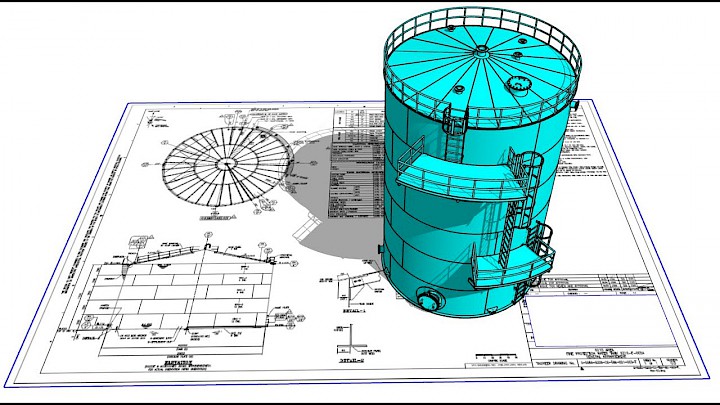

API 650 Tank: Tank Manufacturing Compliant with Standards

API 650 tanks are reliable and durable tanks used for storing liquids or gases in industrial settings. These tanks are manufactured in accordance with the API 650 standard published by the American Petroleum Institute (API). API 650 tank manufacturing requires proper design, appropriate material selection, and a meticulous production process.

At Aces Process, we stand by your side with our API 650 compliant tanks for your industrial storage solutions. API 650 is one of the most important standards for the design, manufacture, and installation of welded steel storage tanks in the petroleum industry. We are a leader in meeting storage needs by providing our customers with high-quality, reliable, and durable tanks.

The tanks we manufacture in accordance with API 650 standards offer several advantages. Here are some key features we can offer you:

-

Reliability: API 650 provides comprehensive design and structural requirements to ensure the safe and secure operation of tanks. Our tanks meet high standards in terms of leak-proofness, durability, and structural integrity.

-

Flexible Design: API 650 standards allow for the design of tanks in various sizes, shapes, and capacities. We offer customized solutions to best meet your storage needs, providing flexibility to suit your specific requirements.

-

Long Service Life: The use of quality materials and a precise manufacturing process ensures the longevity of API 650 tanks. Our tanks are resistant to environmental effects, corrosion, and other abrasive factors.

-

Quality Control: The manufacturing process of our tanks is carried out with strict quality control protocols and in accordance with standards. Tests and inspections carried out at every stage ensure that we deliver products of superior quality.

-

Compliance: Our API 650 tanks are designed in compliance with industry standards and are fully compliant with local regulations. This ensures that your projects operate in accordance with regional regulations and requirements.

Our API 650 compliant tanks have a wide range of applications in the petroleum, chemical, energy, water, food, and other industries. Our experienced team and technical experts will guide you through every stage of your project to provide the most suitable tank solutions.

At Aces Process, we offer a service focused on safety, quality, and customer satisfaction with our API 650 compliant tanks. Our tanks are optimized to meet your liquid and gas storage needs and perform beyond industry standards.

The usage areas of our API 650 compliant tanks are quite extensive. We provide reliable storage solutions in oil refineries, chemical plants, power plants, water treatment plants, food processing plants, and many other sectors. The storage capacity, size, shape, and configuration of the tank can be customized to your needs.

The safety of our customers and the performance of our tanks are our priorities. Each tank is carefully designed by our qualified engineers and undergoes strict quality control processes. The high-quality steel materials used in production and the latest welding equipment ensure the construction of durable and long-lasting tanks.

In addition to our API 650 tanks, we also offer support services such as installation, maintenance, and repair. Our professional teams carry out the installation of the tanks according to the requirements of your project and provide regular maintenance work.

At Aces Process, we are a leader in the industry with our API 650 compliant tanks. With our customer-focused approach, quality products, and experienced team, we are happy to be by your side at every stage of your project.

Contact us to provide reliable, durable, and cost-effective tank solutions for your storage needs!

In the continuation of our article, we have covered API 650 compliant tanks in detail. We wish you pleasant reading.

Some of the frequently asked questions about API 650 tank manufacturing are:

-

What does the API 650 standard mean?

-

What documents are needed for API 650 tank manufacturing?

-

What materials are used in API 650 tank manufacturing?

-

How long does API 650 tank manufacturing take?

-

What tests are done for API 650 tank manufacturing?

-

What welding methods are used for API 650 tank manufacturing?

-

What safety precautions should be taken for API 650 tank manufacturing?

-

What factors affect the price for API 650 tank manufacturing?

-

API 650 tank design

What does the API 650 standard mean?

API 650 is a standard published by the American Petroleum Institute (API). The full name of this standard, "API 650: Welded Steel Tanks for Oil Storage," specifies the requirements for welded steel storage tanks used in the petroleum industry.

The API 650 standard provides comprehensive guidance on design, material selection, manufacturing, installation, testing, and maintenance. This standard aims to ensure that storage tanks are built safely, durable, and in compliance with environmental regulations.

The API 650 standard covers the following topics:

-

Tank Design: API 650 specifies the design requirements for tanks, such as sizing, shape, pressure resistance, strength against load and earthquake effects.

-

Material Selection: API 650 specifies the properties and acceptable standards of steel materials used in the construction of tanks. This is a regulation made to ensure the durability and longevity of the tanks.

-

Manufacturing and Installation: API 650 provides specific requirements for the tank manufacturing process. This includes welding techniques, testing, quality control, leak tightness checks, and other manufacturing steps.

-

Testing: The API 650 standard requires that manufactured tanks be tested for quality and safety. This includes hydrostatic tests, penetrant tests, ultrasonic tests, radiographic tests, and other inspection methods.

-

Maintenance and Repair: API 650 provides recommendations for ensuring the regular maintenance and periodic inspections of tanks. This is important to keep the tanks running safely and efficiently.

The API 650 standard is an industry-accepted benchmark and is used in tank manufacturing and storage operations in various countries. Tanks built in accordance with this standard meet safety standards and provide a solid foundation for meeting liquid or gas storage needs.