What is Biogas?

Biogas, obtained as a result of the anaerobic fermentation of organic matter, is a combustible gas similar to natural gas due to its properties. Biogas consists of 40-70% methane (CH4), 60-30% carbon dioxide (CO2), and other gases such as hydrogen sulfide (H2S), nitrogen (N2), hydrogen (H2), and carbon monoxide (CO). It can be easily used in all devices that run on natural gas or LPG with minor modifications. The appeal of biogas systems lies in their use of organic waste, which causes environmental and health problems, as input and converting this waste into value.

Animal waste, which is found in large quantities, especially in rural areas, is one of the most important inputs for biogas systems. This waste is either stored for long periods and used as fertilizer in agricultural applications, or converted into a form known as manure and burned inefficiently. This is where biogas technologies come to the fore. These systems enable animal waste to be used without being stored, providing high-energy biogas along with organic fertilizer that is free of weed seeds and pathogens and has a high nitrogen content suitable for plant use.

What is Bioenergy?

Biomass is defined as all non-fossil organic matter of biological origin that can be renewed in less than a 100-year period, including plants growing on land and in water, animal waste, food industry and forest by-products, and municipal waste. Energy obtained from these sources is called biomass energy. Energy is stored in biomass through photosynthesis, and its efficiency is less than 1%. Global fossil energy consumption is equivalent to 0.01% of the total annual solar radiation. In general, the energy stored through photosynthesis is about 10 times the annual global energy consumption. However, less than 1.5% of this energy is used.

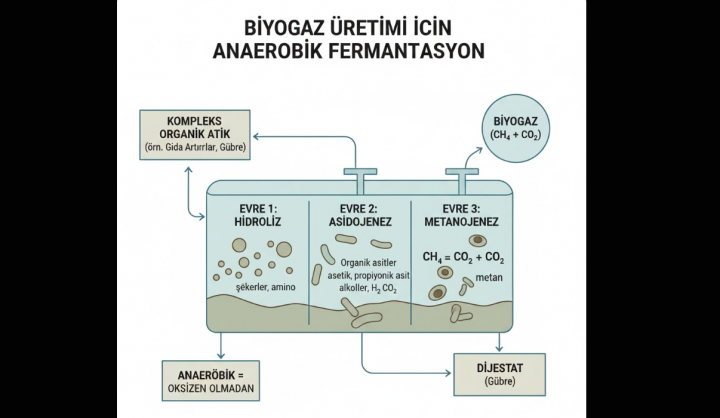

Anaerobic Fermentation

Anaerobik fermentasyon, organik malzemelerin oksijensiz ortamda yaşayan bakteriler tarafından bozulmasıdır. Bu bozulma sonucunda organik gübre ve biyogaz açığa çıkmaktadır. Aerobik fermentasyonda ise başlıca karbondioksit ve kompost gübre elde edilir. Anaerobik fermentasyonda ise aerobik fermentasyonun tersine, organik maddelerin mineralizasyonu çok az miktarda yeni bakteri hücresi üretimiyle mümkün olmaktadır.

The History of Biogas

It may be surprising, but biogas was first used by the Assyrians around 1000 BC. Pliny, who lived between 23 and 79 AD, mentions flames flickering over marshes. In the 17th century, Jan Baptista Van Helmont noted that combustible gas was produced by the decomposition of organic matter. In 1682, Robert Boyle stated that gas production was achieved by decomposing animal and plant waste. In 1776, Count Alessandro Volta demonstrated the relationship between the amount of decomposed organic matter and the amount of combustible gas produced. Between 1804 and 1810, John Dalton, Sir Humphry Davy, and William Henry proved that methane could be produced from cattle manure through anaerobic fermentation. Avogadro defined CH4 in 1821. In 1868, Bechamp, and in 1873, Popoff attributed the phenomenon causing methane production to bacteria. Its history continues in this manner, with references dating back to centuries BC and continuing to the present day.

Stages of Biogas Formation

Biogas production is a sensitive biochemical reaction chain consisting of four main stages and managed by microorganisms. This process converts organic waste into valuable methane gas. The main steps in biogas formation are as follows:

-

Hydrolysis (Breakdown Phase): The breakdown of complex organic polymers (carbohydrates, proteins, lipids) that make up biomass by extracellular enzymes called hydrolases. The separation of insoluble polymers into simple, soluble monomers that can pass through cell membranes.

-

Acidojeneis (Acid Formation Phase): The fermentation of monomers obtained from hydrolysis by acidogenic bacterial groups. Formation of volatile fatty acids, alcohols, lactic acid, and inorganic gases.

-

Acetogenesis (Main Product Formation Phase): The conversion of acidogenesis products into acetate, H2, and CO2 by acetogenic bacteria. These reactions are thermodynamically possible only if the partial pressure of H2 is kept low. This requires obligate symbiosis with methanogenic archaea.

-

Methanogenesis (Energy Production Phase): The final metabolic activity of methanogenic archaea, converting acetate, H2, and CO2 into methane CH4 and CO2. Acetoclastic methanogenesis and hydrogenotrophic methanogenesis.

Applications of Biogas

Biogas can be used directly for combustion to produce hot water and hot air, for drying, and for generating heat and power by producing steam. It can also be used as fuel in internal combustion engines to produce mechanical work and electricity. Another area of use is heating and cooling by absorption. Its use in gas turbines requires the complete removal of water vapor and other residual gases it contains. Especially in countries with rural settlements not connected to the electricity grid, biogas can also be used for lighting purposes by burning it directly on small-scale farms. When biogas is used in drying and especially in incubators, the payback period for the system investment is reduced. When the fermented fertilizer obtained is important to the system, it is economical to use biogas to dry or sterilize this waste.

• Heat Generation

• Energy Production

• Mechanical Work Production

• Heating and Cooling

• Gas Turbines

• Lighting

• Drying

• Incubator Energy

Biogas Reactors

Reactors are generally classified into two types based on their feeding method: batch-fed type and continuous-fed type.

• Batch-fed reactors: Feed material is loaded into the reactor once and left until gas production ceases or decreases. It is then emptied and new material is added. These reactors are advantageous where feed material is not available in sufficient quantities or is only available seasonally, or where the feed material has a coarse-grained structure.

• Continuous-feed reactors: Material is added at regular intervals, and the same amount of fermented material is discharged. Continuous feeding and discharge is ideal for continuous-feed reactors. However, this is not feasible in practice.

Types of Bioreactors

The main types of these reactors are as follows:

• Anaerobic filter reactors,

• Solid-Upflow reactors

• Solid-recycling stirred-type reactors

• Upflow anaerobic reactors

• Anaerobic contact reactors

• Fluidized bed reactors

• Fixed film reactors

• Sequential batch reactors

• Two-phase reactors

Is Biogas Renewable Energy?

Biogas is undoubtedly a renewable energy source. This is because its raw material, organic waste (biomass), is obtained from continuously renewable and cyclical sources such as agricultural activities, livestock farming, and municipal waste. The carbon dioxide emitted into the atmosphere as a result of its combustion is considered carbon-neutral, as it has already been absorbed by plants in the natural cycle.

As Aces Process, we are an expert engineering company with over 30 years of solid experience in the production of bioreactors and fermenters, primarily for the chemical and food industries. We design customized industrial reactors tailored to our customers' specific needs, manufacture them to high standards, and provide turnkey installation for your facility.