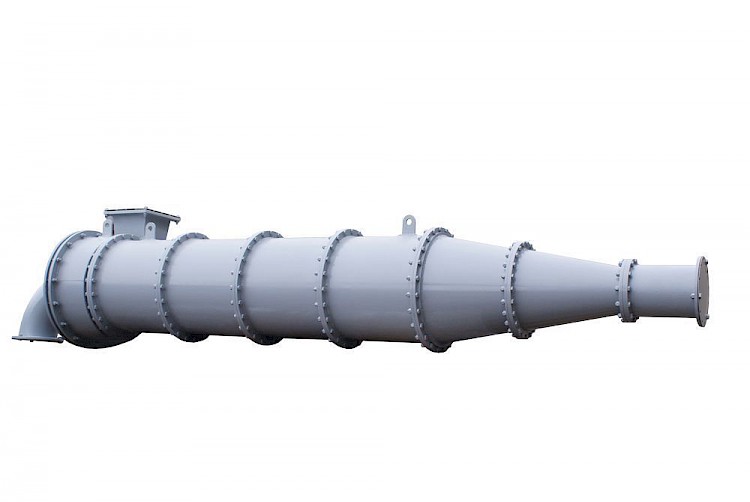

Cyclone Manufacturing: High-Performance, Industry-Specific Solutions

Aces Process delivers high-quality cyclone manufacturing tailored to the diverse needs of various industries. In our design and production processes, we utilize advanced manufacturing and design technologies to offer long-lasting, efficient, and cost-effective cyclone solutions.

What is a Cyclone?

Cyclone separators are industrial equipment that efficiently separate solid particles from gas streams by utilizing centrifugal force. These systems improve process efficiency and minimize environmental impact by functioning as both primary dust collectors and pre-cleaning units in dust removal processes.

Industries and Application Areas of Cyclone Separators

Cyclone separators are preferred in a wide range of industries for particle separation, dust collection, and gas purification processes. Below, we discuss the use and benefits of cyclone separators from an engineering perspective across various sectors.

-

In Processes Handling Abrasive Materials: Industries like mining, ceramics, and sand processing require effective separation and transportation of abrasive particles. Cyclones with wear-resistant steel or composite bodies are chosen to withstand highly abrasive materials.

-

In Packaging Machinery and Automation Systems: Fine dust generated on packaging lines can affect product quality and reduce machine efficiency. Cyclones installed along production lines ensure fast and uninterrupted dust separation.

-

In Food Processing and Hygienic Facilities: In food production facilities, the separation of fine particles like flour, sugar, and starch is crucial for hygiene and product quality. Cyclones used in food processes are produced from stainless materials that meet hygienic standards.

-

In Chemical, Pharmaceutical, and Cosmetic Processes: Controlling dust during chemical reactions, or in pharmaceutical and cosmetic production lines, is essential for both environmental and operational compliance. Precision cyclones with low-pressure loss are preferred in these industries.

-

In Grinding, Screening, and Separation Processes: Dust generated during grinding and screening can reduce operational efficiency and damage equipment. High-efficiency cyclones help optimize the process by separating ground material effectively.

-

In the Wood and Timber Industry: In furniture production, lumber processing, and wood industries, separating sawdust and fine particles is essential for occupational health and safety. Wood dust cyclones help control dust in the workplace and reduce fire risks.

-

In the Paper and Pulp Industry: Cyclones are used to separate dust and fibers generated during paper and pulp production. Optimized cyclone geometries help keep production lines clean and prevent process interruptions.

-

In PVC Stabilizer and Other Powder Handling Systems: Cyclones are preferred to efficiently separate fine particles generated during the handling of stabilizer powders and chemicals in PVC production. Preventing dust accumulation improves equipment performance.

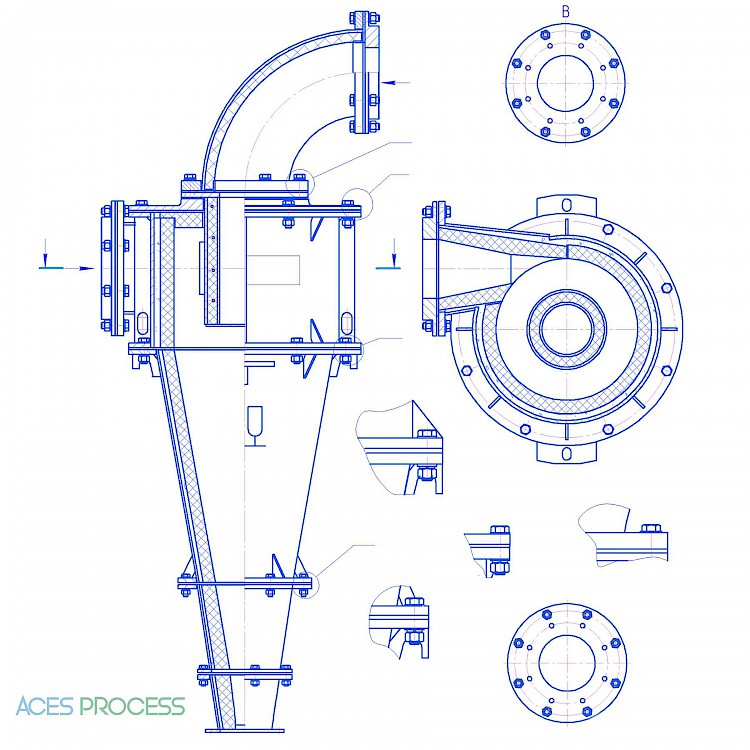

How Does a Cyclone Work?

The operating principle of a cyclone involves the tangential entry of dirty gas at high velocity. This entry induces a circular motion inside the cyclone. Particles within the rotating gas are pushed outward by centrifugal force and collide with the cyclone walls. Under the influence of gravity, these denser particles collect in the bottom chamber of the cyclone. Meanwhile, the cleaned gas exits from the top outlet. In this process, particle inertia plays a key role in separation.

Types of Cyclones

-

Multi-Cyclone: Systems where multiple cyclones are connected in parallel or series for applications requiring high efficiency.

-

Axial Cyclone: Gas flow is parallel to the axis, suitable for processes where low-pressure loss is required.

-

Tangential Cyclone: In this design, the flow enters tangentially, providing high-speed particle separation.

Cyclone Dimensions and Design

Cyclone design is determined by critical parameters such as flow rate, particle size, flow velocity, and separation efficiency, based on the process requirements. Correct design aims to reduce operational costs while maximizing separation efficiency. The dimensions and geometry of the system are optimized by considering particle density and the characteristics of the material being separated.

Design Parameters and Optimization

-

Flow Rate: The amount of gas or air flow determines the cyclone’s diameter and height ratios. Larger cyclones are preferred for higher flow rates.

-

Particle Size: While finer dust requires more precise separation, standard designs suffice for larger particles. The cyclone design follows separation efficiency curves for optimal performance.

-

Separation Efficiency: This indicates what percentage of particles are efficiently separated from the system. Aces Process designs multi-cyclone systems to achieve high efficiency and adds filter modules if needed.

-

Pressure Loss: Efficient cyclone designs aim to provide high separation performance with minimal pressure loss.

Aces Process Expertise in Cyclone Design

Aces Process ensures maximum performance in your processes by developing cyclone systems tailored to the needs of each sector. During the design phase, we use calculation software and simulations to analyze flow profiles, separation efficiency, and flow rates in advance, preventing potential efficiency losses and pressure drops.

Custom Designs and Tailored Solutions

-

On-site inspection and consulting: We conduct on-site assessments to design systems tailored to your business needs.

-

Customized simulations: For each project, simulations for different scenarios help determine the optimum cyclone dimensions.

-

Material selection: For abrasive environments, we provide durable steel or composite-bodied cyclones.

Aces Process excels in designing and applying multi-cyclone, tangential, and axial cyclone models to meet the needs of both high-flow processes and precise filtration systems.

Advantages of Working with Aces Process

-

Comprehensive support for design, manufacturing, and installation: We manage your project end-to-end, guiding you through the entire process.

-

Fast delivery and after-sales service: Timely delivery and long-term support ensure uninterrupted operations.

-

R&D and Innovation: We continuously develop innovative designs to keep your systems up-to-date with the latest technologies.

Trust Aces Process experts to achieve optimal cyclone design and high efficiency in your operations. With our customized solutions, we help you boost productivity while reducing costs.