Decanter Manufacturing: Centrifuges and Separators

Separating liquids and solids in industrial operations is a crucial process. Achieving this efficiently and effectively is critical to a company's performance, productivity, and profitability. In this context, decanters play a significant role. When combined with Aces Process manufacturing, decanters become high-performance devices that offer industrial advantages.

Aces Process provides the most cost-effective and high-performance decanter solutions for industrial applications, offering significant benefits to businesses. These decanters are specially designed and manufactured according to process requirements, and they have a durable structure for separating corrosive, abrasive, and aggressive types of products. Additionally, the use of high-quality materials ensures long-lasting and reliable performance.

The key industrial advantages of Aces Process decanters are:

-

Durability and Chemical Resistance in Decanters Process industries often face the risk of exposure to chemicals. Aces Process decanters are designed to withstand such aggressive environments. They offer resistance to corrosive effects through specially selected materials and coatings, ensuring long-lasting use.

-

High Performance in Decanters Aces Process decanters exhibit superior performance in separation processes that require high performance in process industries. Their efficient design and optimized operating principles ensure high separation efficiency. This provides significant advantages in terms of business productivity and process efficiency.

-

Cost-Effectiveness in Decanters Aces Process decanters offer a cost-effective solution for businesses. The use of advanced technology and high-quality materials ensures long-lasting and reliable performance while keeping maintenance and operating costs low. This helps businesses optimize their operating expenses.

-

Flexibility and Adaptability in Decanters Aces Process decanters offer flexibility and adaptability to meet the diverse needs of various process industries. They can be produced in different sizes and capacities to suit businesses of different scales. Additionally, they can be customized to meet specific process requirements, providing the best solution for the specific needs of businesses.

-

In conclusion, Aces Process decanter varieties provide cost-effective and high-performance solutions in process industries, giving businesses a competitive advantage. Their durable structure, high performance, cost-effectiveness, and flexible adaptability increase the efficiency of process separation processes and contribute to business success.

Frequently Asked Questions about Decanters and Our Experts' Comments:

-

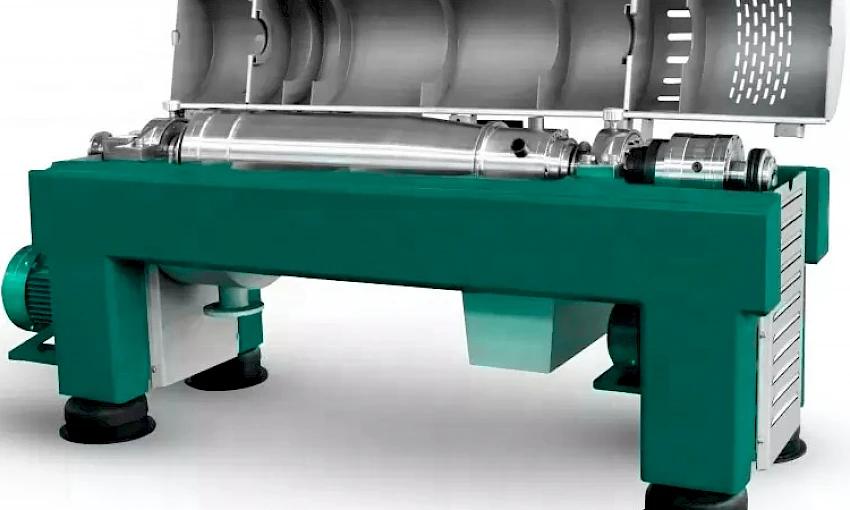

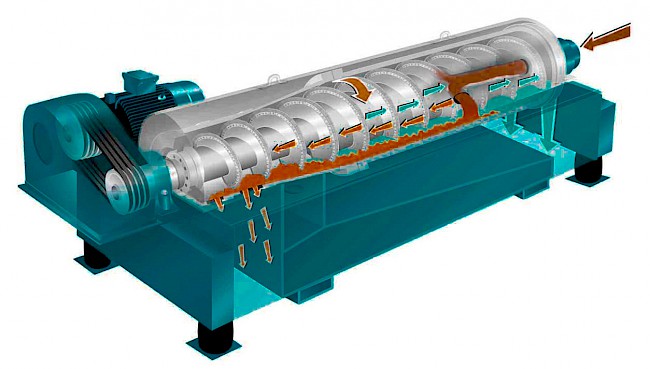

What is a Decanter? A decanter is an industrial equipment used to separate liquid and solid materials. It operates based on the principle of centrifugation, separating materials according to their density.

-

What is a Decanter Used For? A decanter is an industrial equipment used to separate liquid and solid materials. Its function is to separate the mixture inside it according to density differences, causing the solids to settle at the bottom due to the effect of gravity. It is used in various industrial processes such as wastewater treatment, chemical production, food processing, and oil refineries for separating, cleaning, or concentrating materials. Decanters offer significant advantages in terms of efficiency, performance, and operational continuity.

-

What is the Price of a Decanter? Decanter prices can vary greatly depending on various factors. Prices are determined by factors such as the design, features, size, capacity, material quality, and manufacturing process of the decanter. Therefore, to determine the price of a specific decanter, you can directly contact us and receive a quote tailored to your business needs.

-

Where are Decanters Used? Decanters have a wide range of applications in various industries. Some of the common sectors where decanters are used include: Water and Wastewater Treatment, Chemical Industry, Food and Beverage Industry, Petroleum and Gas Industry, Mining and Ore Processing, Pharmaceutical Industry.

-

How Does a Decanter Work? What is the Working Principle of Decanters? Decanters are industrial equipment used to separate liquid and solid materials. Their operating principle is based on the interaction of gravity and centrifugal force. Here is a general explanation of how decanters work in 5 steps:

-

Liquid-Liquid Separation Decanter: Decanters are used to separate two liquids with different densities in chemical processes. For example, they are used in processes such as solvent-solvent separation or oil-water separation.

-

Solid-Liquid Separation Decanter: Decanters are used to separate solid and liquid materials in chemical processes. For example, they can be used to separate solid particles from solutions formed as a result of chemical reactions or to dehydrate sludge in chemical production processes.

-

Sedimentation Decanter: Decanters are used in chemical processes to settle and separate solid particles in sludge, suspensions, or solutions. This process is known as sedimentation, and decanters are used to accelerate this process.

-

Emulsion Breaking Decanter: Decanters can be used to break down and separate emulsions formed in chemical processes. Emulsions are mixtures formed by the dispersion of one liquid phase in another liquid phase, and decanters can be effective in separating these emulsions.

Aces Process designs and optimizes decanters according to the needs of each chemical process.