Homogenizer Manufacturing

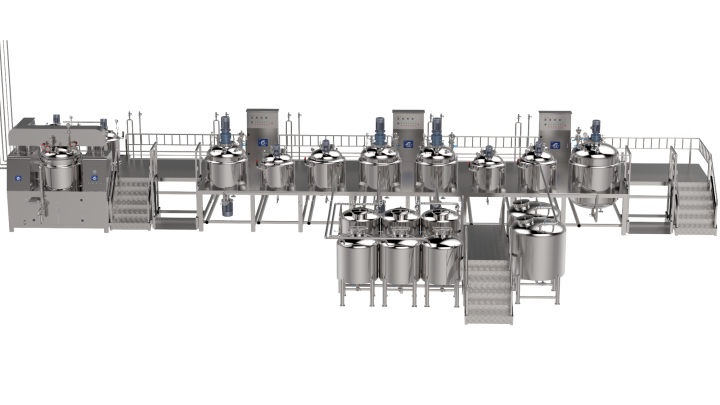

Aces Process, as an engineering company specializing in the field, offers groundbreaking services in the design and manufacture of homogenizers for the chemical, food, and cosmetic industries. With years of experience and our innovative approach, we maintain our leading position in the sector by providing customized homogenization solutions tailored to our customers' needs. In this article, you will discover Aces Process's expertise and success stories with homogenizers.

Engineering Expertise in Homogenizer Design:

Aces Process utilizes its engineering expertise in homogenizer design to provide customized solutions to its customers. Our engineering team optimizes homogenization processes by selecting the latest technologies, the most suitable materials, components, and processes in the industry. This enables us to provide our customers with high-performance and efficient homogenizer systems.

Quality and Precision in Manufacturing:

Aces Process adopts the highest quality standards in homogenizer manufacturing. In our advanced production facilities, we manufacture homogenizer machines equipped with the industry's leading equipment and technologies.

Customer-Specific Solutions:

At Aces Process, we understand the unique needs of each customer and tailor our homogenizer designs accordingly.

Aces Process, as an engineering company specializing in Homogenizer Machines, continues its leadership in the sector. We combine our engineering skills, quality-focused manufacturing, and customer-centric approach to provide customized homogenizer solutions. By working with us, you can access high-performance and reliable solutions that will meet your homogenizer needs at the highest level.

Homogenizer Mixer

A homogenizer mixer is a high-performance equipment used in the chemical, food, and cosmetic industries. Thanks to the systems within Homogenizer Tanks, it mixes substances of different densities homogeneously, improving product quality. With its durable structure and precise control mechanisms, it ensures efficient and reliable homogenization processes.

Homogenizer Prices

Homogenizer prices vary depending on their intended use, capacity, and technical specifications. Industrial homogenizers are generally in a higher price range, while laboratory-scale homogenizers are manufactured at more affordable prices. You can contact us for a special Homogenizer price quote for your business.

Homogenizer Working Principle

Homogenizers use high pressure and rapid rotational movement to ensure that materials are mixed homogeneously. The specially designed wing and blade systems inside compress and break down the materials at high speed, achieving a homogeneous consistency. This process reduces particle size and ensures that the mixture has the desired properties.

Types of Homogenizers

Homogenizers are produced in various types according to different industrial applications. Some commonly used types of homogenizers are:

-

High-Pressure Homogenizer: These types of homogenizers achieve a homogeneous mixture by compressing materials under high pressure. They are generally used in the food and cosmetic industries.

-

Ultrasonic Homogenizer: Ultrasonic homogenizers use ultrasonic waves to homogenize materials. These waves help break down and mix the materials. This type of homogenizer is often used in laboratory applications.

-

Jet Homogenizer: Jet homogenizers mix materials in a high-velocity jet stream. This method is effective for the rapid homogenization of liquids and is often used on an industrial scale.

-

Diaphragm Homogenizer: Diaphragm homogenizers homogenize materials under the influence of a high-speed rotating diaphragm. This type of homogenizer is often used in laboratory and industrial scale.

-

Static Mixers: Static mixers homogenize materials using designs with fixed geometry instead of moving parts. This type of homogenizer is often used in continuous flow systems and provides energy efficiency.

These homogenizer types are preferred according to different application areas and mixing requirements. Each homogenizer uses different working principles to ensure the homogeneous mixing of materials.

Milk Homogenizer

Milk homogenizers are a special type of homogenizer commonly used in the dairy industry. These homogenizers break down the fat molecules in milk into smaller sizes, achieving a homogeneous consistency. This ensures better distribution and stability of the fat in the milk, resulting in a creamy texture. Milk homogenizers provide better taste, consistency, and quality in dairy products.

Frequently Asked Questions and Expert Comments about Homogenizers:

What is a Homogenizer?

Homogenization is essentially the process of combining two or more substances to form a homogeneous mixture. This process enables the transition from a heterogeneous system to a homogeneous system by bringing together substances with different densities and solubilities.

What is the purpose of a homogenizer?

The tasks of homogenizers are to reduce the particle size of products, increase stability, and ensure a more homogeneous and stable structure.

What is a homogenization machine?

Widely used in industries such as chemical, food, and cosmetics, homogenizers are stainless steel equipment used to obtain a homogeneous product by mixing different substances together.

How is homogenization done?

The homogenization process is a method used to obtain a homogeneous mixture of substances with different densities. The process, which starts with the preparation of the materials, involves setting the homogenization device appropriately. The materials are added to the device and mixed with high pressure and rotational movement, during which the particle size is reduced, and a homogeneous consistency is formed.

What does homogenized food mean?

Homogenized food refers to food products that have been processed by homogenization and have reduced particle size.This process is usually applied to milk and dairy products. Homogenized milk offers a better taste and texture due to the better distribution of fat and its creamy texture. Homogenized foods have a longer shelf life and provide a better consumer experience.