Heat Exchanger Manufacturing: Heat Exchangers

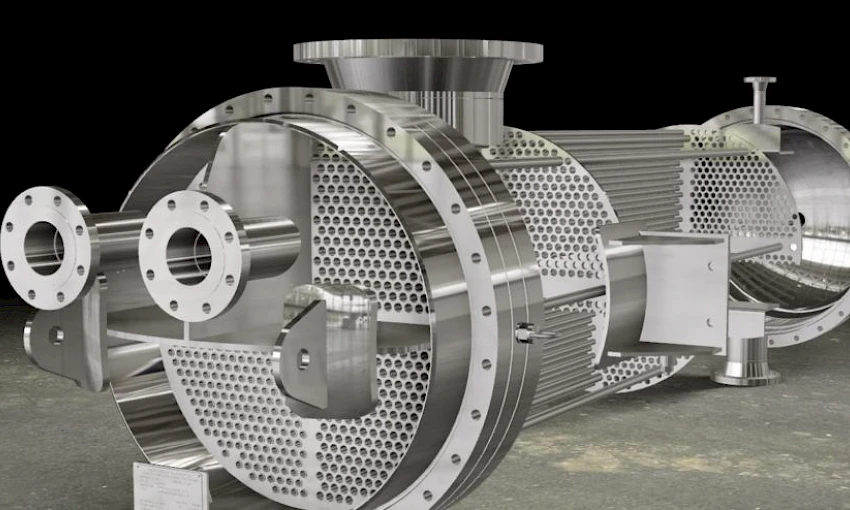

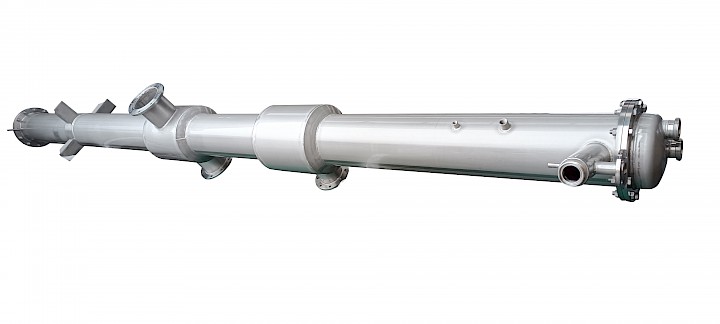

Heat exchangers are essential components in industrial applications, ensuring energy efficiency and optimizing heat transfer. If you're searching for a reliable and expert manufacturer for your heat exchanger needs, we at Aces Process offer professional support to our clients in every step of the heat exchanger project, from design to production and assembly to commissioning.

Heat Exchanger Manufacturing Process

The heat exchanger manufacturing process is meticulously managed by Aces Process's expert engineering team. At every stage of the manufacturing process, we adhere to the highest standards of quality, accuracy, and excellence. By utilizing the latest techniques and innovative approaches, we provide our customers with customized designs.

Heat Exchanger Design and Manufacturing

Heat exchanger design and manufacturing are among Aces Process's core competencies. Our company collaborates with field-expert engineers to provide optimized designs tailored to our clients' needs and operational processes. Aces Process Engineers, Technicians, and Craftsmen manage the design and manufacturing processes in an integrated manner to ensure the production of efficient and reliable heat exchangers.

Quality Control in Heat Exchanger Manufacturing

Quality control methods are strictly implemented by our company in heat exchanger manufacturing. We conduct tests,inspections, and quality control procedures at every stage of the manufacturing process to ensure quality assurance. This way, we provide our customers with high-quality and reliable products.

Expertise in Welding Techniques

Aces Process also specializes in welding techniques in heat exchanger manufacturing. Our company utilizes advanced welding techniques in line with European standards to provide heat exchangers with excellent performance to our customers.

Collaboration with International Inspection Companies

Aces Process manages the heat exchanger manufacturing process in full cooperation with internationally recognized inspection companies. By working with reputable inspection companies such as TUV Nord and TUV Austria, we guarantee that the manufacturing process complies with international standards in terms of reliability, quality, and compliance.

The Importance of the Inspection Process

The inspection process is a crucial step in ensuring that our products comply with internationally recognized standards and quality management systems. For this reason, we prefer independent and competent inspection companies such as TUV Nord and TUV Austria. These companies ensure that our manufacturing process is evaluated fairly, objectively, and impartially.

The inspection companies we collaborate with conduct inspections at every stage of our heat exchanger manufacturing.They thoroughly examine critical points such as material selection, processing procedures, welding methods, quality control steps, and tests. These inspections verify that our products meet international standards and enable their certification.

In this way, we can offer our customers internationally certified and high-quality heat exchangers. Our collaboration with inspection companies like TUV Nord and TUV Austria provides us with strong support in providing our customers with products that meet the highest standards in terms of reliability, performance, and compliance.

Innovative Technologies and Developments in Heat Exchanger Manufacturing

Innovative technologies and advancements are a priority for Aces Process in heat exchanger manufacturing. Our company closely follows the latest technological developments in the industry and adopts these technologies to improve efficiency,safety, and quality in the manufacturing process.

Frequently Asked Questions about Heat Exchangers:

-

Why are heat exchangers used?

-

What is the purpose of an exchanger?

-

How does a heat exchanger work?

-

Where are shell and tube heat exchangers used?

-

What materials are heat exchangers made from?

-

What is a boiler heat exchanger?

Why are heat exchangers used?

Heat exchangers are equipment used to transfer heat between two fluids at different temperatures. Heat exchangers offer numerous advantages, such as increasing energy efficiency, enabling heat recovery in processes, providing temperature control, and reducing costs.

What is the purpose of an exchanger?

Exchangers are used to transfer heat between liquids, gases, or vapors. Heat exchangers are widely used in energy-intensive industries, air conditioning systems, power generation, the chemical industry, food processing plants, and many other applications.

How does a heat exchanger work?

Heat exchangers utilize heat exchanger tubes or plates, which are metallic surfaces that separate the fluids while allowing heat transfer. The hot fluid passes through the tubes or plates, transferring heat to the cold fluid. This way, energy transfer is achieved between the two fluids.

Where are shell and tube heat exchangers used?

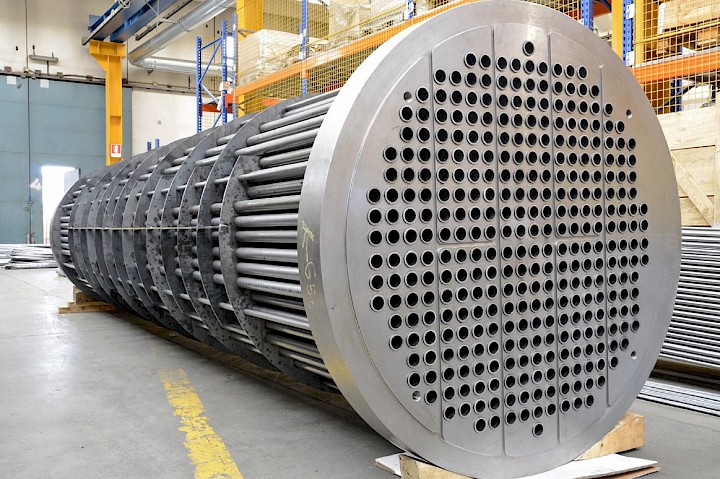

Shell and tube heat exchangers are commonly used in high-pressure and high-temperature applications. For instance, they are preferred in power plants, the petrochemical industry, refineries, heating systems, and steam boilers. Shell and tube heat exchangers provide efficient heat transfer through the arrangement and optimization of tube connections.

What materials are heat exchangers made from?

Heat exchangers are manufactured from various materials. These materials include metals such as stainless steel, copper,nickel alloys, aluminum, titanium, and carbon steel. The material selection depends on the application requirements,temperature and pressure conditions, chemical resistance, and cost factors.

What is a boiler heat exchanger?

A boiler heat exchanger is a type of heat exchanger commonly used in heating systems and hot water production. The boiler heat exchanger transfers heat from the high-temperature water within the boiler to the lower-temperature circulating water. This enables hot water production or energy efficiency in heating systems. Boiler heat exchangers are often used in condensing boiler systems and heating systems.

For more comprehensive information about heat exchangers, please visit our Heat Exchanger page. You can also contact us through our contact page to receive a customized quote.