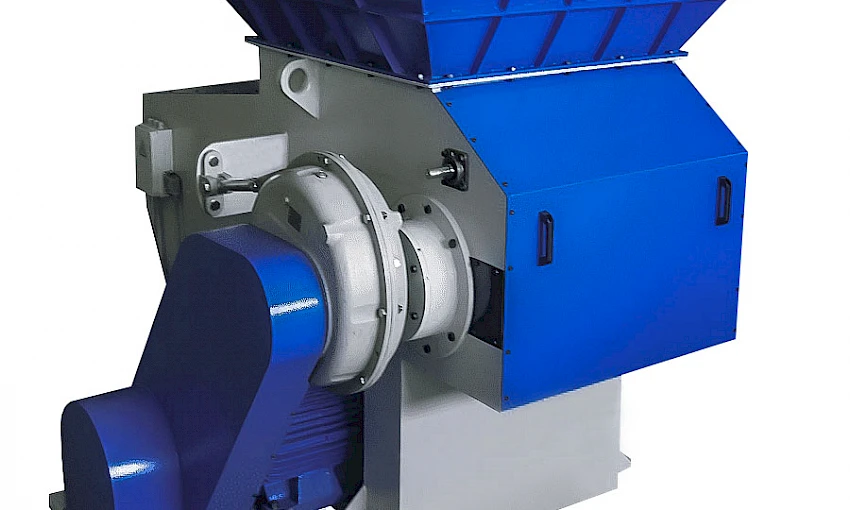

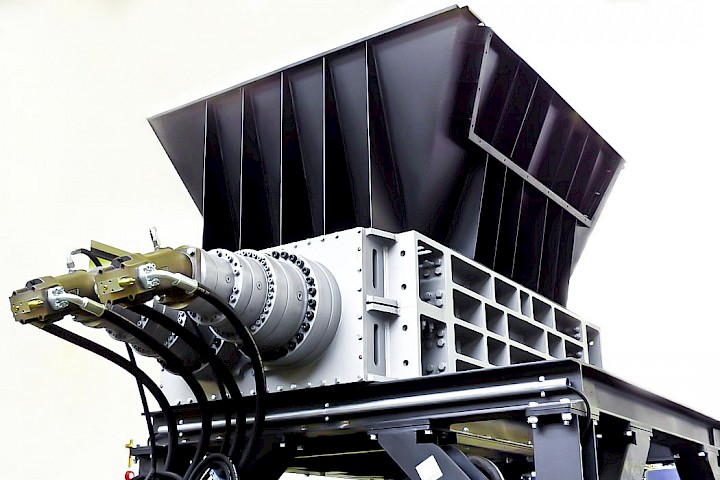

Plastic Crushing Machines: Pioneering Technology in Recycling

The recycling industry plays a critical role in conserving natural resources and building a sustainable future. In this context, the efficient recycling of plastic waste is a crucial step in reducing environmental impact. Plastic crushing machines play a vital role in this process, enabling the effective recycling of plastic waste.

Our company holds a respected position in the industry as a leading engineering company specializing in plastic crushing machines. We provide high-performance and reliable plastic crushing machines specifically designed for our customers.Our aim is to optimize the transformation process of plastic waste by contributing to the recycling industry.

What Can You Achieve with Aces Process Plastic Crushing Machines?

-

High Efficiency: Thanks to our advanced German technology and Turkish engineering principles, our plastic crushing machines provide high efficiency. They accelerate the recycling process and reduce costs by crushing plastic waste quickly and effectively.

-

Flexibility and Versatility: Our plastic crushing machines are designed to process different types and forms of plastic. They successfully process transparent, colored, hard, or flexible plastics, allowing for a wide range of applications.

-

Excellent Quality and Reliability: Manufactured in accordance with superior quality standards, our plastic crushing machines stand out in terms of durability and reliability. Their long-lasting designs guarantee high performance and flawless operation even under continuous working conditions.

-

Ease of Use and Maintenance: Our plastic crushing machines are equipped with user-friendly interfaces and can be easily operated. In addition, the simplicity of maintenance and cleaning processes reduces operating costs and ensures production continuity.

Why Choose Us?

-

Design Expertise: Superior German engineering skills and Turkey's strong production capacity enable our plastic crushing machines to revolutionize the recycling industry.

-

Quality and Reliability: We guarantee the quality of our products through our commitment to high-quality standards and the use of durable materials.

-

Technical Support and Service: We attach great importance to customer satisfaction. Our technical support team has the knowledge and expertise to assist you at every stage.

-

Competitive Pricing: The competitive prices of our plastic crushing machines offer excellent value to our customers.

We look forward to working with you to become a leader in the plastic waste recycling process and contribute to a sustainable future. Contact us today for your plastic crushing machine needs and get in touch with our expert team!

Frequently Asked Questions and Expert Comments about Plastic Crushing Machines:

What is a Plastic Crushing Machine?

A plastic crushing machine is a machine used to break plastic waste into small pieces when it is in large pieces, making it processable. This allows plastic waste to be more effectively utilized in the recycling process and used in the production of new products. Plastic crushing machines contribute to environmental sustainability by increasing the transformation potential of waste.

How Much Do Plastic Crushing Machines Cost?

Plastic crushing machine prices can vary depending on several factors. The most important of these factors are the capacity and processing speed of the machine. Plastic crushing machines generally have a wide price range. Basic models with small capacity and low-speed operation start at thousands of dollars, while industrial machines and integrated systems offering high capacity and fast processing can go up to millions of dollars.

How is Plastic Broken Down?

Plastic waste is broken down into small pieces using cutting blades in plastic crushing machines. These pieces are then processed for use in the recycling process.

How Does a Plastic Crushing Machine Work?

A plastic crushing machine generally operates by following these steps:

-

Feeding: Plastic waste is conveyed to the feeding section of the machine.

-

Crushing and Cutting: Plastic waste is cut, crushed, and broken with the help of crusher blades or rotors. These blades usually rotate at high speed and break the plastics into pieces of the desired size. In this step, the size and degree of breakage of the plastic waste can be controlled depending on the blades used and the machine settings.

-

Separation and Classification: Plastic crushing machines are equipped with various systems to separate and classify plastic parts.

-

Output: The crushed and classified plastic pieces are transported from the machine by conveyor to the area where they will be stored.

How is Plastic Separated?

Plastic separation is usually carried out by the following methods:

-

Density Separation: By taking advantage of the different densities of plastics, they are separated in specially designed water baths or density separation machines.

-

Magnetic Separation: Plastics with magnetic properties can be separated from metals such as iron or steel using magnetic separation machines.

-

Optical Separation: Using optical sensors and image processing technologies, plastics can be separated according to their color and optical properties.

These methods are used to effectively perform the separation process based on the different properties of plastic waste.

Conclusion

Plastic crushing machines make a significant contribution to environmental protection efforts by enabling the effective management of plastic waste. These machines, combined with innovative designs and production power, aim to take steps towards a sustainable future while revolutionizing the recycling industry. Plastic crushing machines are the cornerstones of an environmentally friendly and economically efficient recycling process.