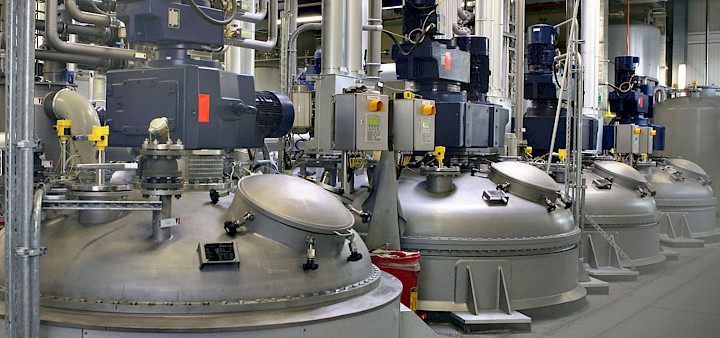

Polyurethane Production Plants

Polyurethane production plants are specialized facilities where polyurethane, a versatile and durable polymer material, is produced and processed. Polyurethanes can be manufactured in various forms, such as foam, elastomers, and plastics,making them suitable for thousands of different applications ranging from automotive and construction to furniture and medicine.

Polyurethane plants are an indispensable part of modern industry. Every polyurethane molecule produced in these facilities contributes to making our lives safer, more comfortable, and sustainable.

Aces Process is an engineering company specializing in the installation and manufacturing of machinery for polyurethane plants. These facilities require specialized equipment for the efficient production of high-quality and durable polyurethane materials. This equipment ensures the efficient operation of the plants and the production of high-quality products.

Synergy of German Engineering and Turkish Production Power:

Aces Process offers a unique opportunity to its customers by combining German engineering and Turkish production power.

German Engineering:

-

Focus, discipline, and precision

-

Production processes based on solid foundations

-

Innovative solutions

Turkish Production Power:

-

Dynamic, flexible, and competitive structure

-

Creative and cost-effective production methods

-

Superior workmanship and production skills

This combined expertise provides significant advantages to customers in the installation of polyurethane plants:

-

Quality: Production at the highest quality standards

-

Efficiency: Maximum production capacity and optimization

-

Customer Satisfaction: Solutions tailored to specific needs

Advantages of Aces Process:

-

Expertise and experience

-

Excellent design and production processes

-

Projects completed on time

-

Customer-focused approach

Conclusion:

Aces Process offers excellence in the installation of polyurethane plants with the synergy of German engineering and Turkish production power. It meets customers' expectations with high-quality and efficient production solutions.

Our expert engineers are a click away. Contact us now and take the first step for your perfect polyurethane plant!

Read on to explore the limitless potential of the polyurethane world, its unique properties, industrial advantages,application areas, and its world filled with innovation and advanced technology.

Polyurethane Plant Installation

Polyurethane is a versatile polymer material widely used in today's industry in a wide range of applications, from insulation to automotive parts, furniture to footwear. Polyurethane stands out with its durability, flexibility, lightness, and tensile strength, making it a preferred material in many areas.

Professional Solutions for Complex Production Processes:

Polyurethane production is a complex process that involves various stages such as reaction preparation, material feeding,reaction process, formulation, and finishing. Each stage is vital to achieve the desired properties of polyurethane.

Aces Process is an experienced engineering company specializing in polyurethane plant installation. With our expert staff and modern technology, we carry out the flawless installation of plants of all scales and capacities.

Key Elements of the Plant:

-

Reaction Preparation: Precise processing of chemicals used in polyurethane production and preparation for reaction.

-

Material Feeding: Transferring the correct amount of material to the reaction tank at the right time.

-

Reaction Process: The critical stage where the polyurethane polymer is formed. Precise control of parameters such as temperature, pressure, and time.

-

Formulation: Determining the chemical ratios according to the desired properties of the polyurethane.

-

Finishing: Shaping and finalizing the polyurethane.

The Aces Process Difference:

-

Expert engineering staff and experienced team

-

Modern technology and innovative solutions

-

High quality and safe production standards

-

Customer-focused service approach

-

On-time and within budget delivery

What is Polyurethane?

Polyurethane is a versatile and high-performance polymer used in a wide range of applications. Its wide range of properties, from flexible foams to rigid plastics, makes it an ideal material for many industries.

Polyurethane Production:

Polyurethane is produced by the reaction of two chemical compounds called isocyanate and polyol. This reaction results in the formation of the polyurethane polymer. Polyurethane can exhibit different physical and chemical properties depending on the chemical formulation in which the reaction is carried out.

Polyurethane Application Areas:

-

Insulation Materials: Polyurethane foam is widely used for heat and sound insulation in buildings and other structures.

-

Furniture: Polyurethane is used as a filling material in furniture manufacturing, upholstery, and various other parts.

-

Automotive Parts: Polyurethane is used in bumpers, seats, steering wheels, and many other automotive parts.

-

Shoe Soles: Polyurethane is widely used in shoe soles due to its lightness, flexibility, and durability.

-

Spray Foams: Polyurethane spray foams are used to provide insulation and air tightness in buildings.

-

Elastomers: Polyurethane elastomers are durable and flexible materials used in various industrial applications.

Polyurethane Production Methods:

Polyurethane can be produced using different production methods. These methods include:

-

Mold Injection: This method is the most common production method for polyurethane products.

-

High-Pressure Injection: This method is used for the production of high-density and durable polyurethane products.

-

Lamination: This method allows the combination of different polyurethane layers to create more complex products.

-

Foam Spraying: This method allows the polyurethane foam to be sprayed directly onto the application area to provide insulation and air tightness.

-

Casting: This method is used for the production of large and complex shaped polyurethane products.

Advantages of Polyurethanes:

-

High Strength: Polyurethanes are strong materials that offer high strength and durability.

-

Elasticity: Polyurethanes are flexible and impact resistant materials.

-

Lightness: Polyurethanes are much lighter than metal and other materials.

-

Heat and Sound Insulation: Polyurethanes offer excellent heat and sound insulation properties.

-

Wide Application Area: Polyurethanes can be used in many different industries due to being a versatile material.

What are the industries where polyurethane is commonly used?

A wide range of properties, from flexible foams to robust plastics, makes Polyurethane a material that offers innovative solutions in different sectors.

Common Applications of Polyurethane:

-

Insulation Industry: Polyurethane is a preferred insulation material in buildings, cold storage, and logistics facilities thanks to its high heat and sound insulation capability.

-

Furniture Industry: Soft and comfortable furniture cushions, pillows, seat and chair upholstery, bed and pillow materials are produced using polyurethane foam.

-

Automotive Industry: Many automotive parts such as car seats, steering wheels, door handles, interior trim materials, and wheels are produced with polyurethane.

-

Footwear Industry: Durable, comfortable, and lightweight shoe soles and heels are made of polyurethane material.

-

Spray Foam Industry: Polyurethane is one of the main components of spray foams used in various areas such as insulation, waterproofing, and sound insulation.

Apart from these:

-

Sports equipment

-

Marine industry

-

Medical devices

-

Packaging industry

There is also a wide range of uses for polyurethane in many areas such as.

Advantages of Using Polyurethane:

-

High Strength and Durability: Polyurethane is a long-lasting and robust material.

-

Lightness: It is much lighter than metal and other materials.

-

Flexibility: It can be easily adapted to different shapes and is resistant to impacts.

-

Heat and Sound Insulation: It has excellent heat and sound insulation properties.

-

Wide Application Area: It has a wide range of properties that can meet the needs of different sectors.

With these advantages and versatility, polyurethane has become an indispensable material for many industries. New formulations and production methods that are constantly being developed are expanding the usage areas and potential of polyurethanes day by day.

Frequently Asked Questions about Polyurethane:

-

Is polyurethane plastic?

-

How is polyurethane produced?

-

What temperature can polyurethane withstand?

-

How durable is polyurethane?

-

Is polyurethane dangerous?

-

Is polyurethane harmful?

-

Is polyurethane waterproof?

-

How is polyurethane foam produced?

-

How is polyurethane sponge made?

-

What is the raw material of sponge?

-

Is polyurethane natural?

Is polyurethane plastic?

No, polyurethane is not a plastic. Polyurethane is a synthetic polymer material. Polyurethanes permanently harden after curing with an irreversible chemical reaction. In other words, polyurethanes cannot be melted or reshaped once they have hardened. Due to these properties, polyurethanes are preferred as a versatile material that can combine properties such as durability, hardness, elasticity, and chemical resistance.

How is polyurethane produced?

The production of polyurethane is carried out by the reaction of two main components called polyol and isocyanate. Here are the stages of polyurethane production in general:

-

Polyol Preparation: The first step in the polyurethane production process is the preparation of a component called polyol. Polyol is usually a polyether or polyester alcohol such as polyethylene glycol or polypropylene glycol.Polyols are produced to have a predetermined molecular weight and properties.

-

Isocyanate Preparation: The other component is isocyanates. Isocyanates are one of the most commonly used materials in polyurethane production. The main isocyanates used in polyurethane production include toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI).

-

Reaction Stage: The polyol and isocyanate mixture react in a reactor. During this reaction, a polyaddition reaction occurs between the isocyanate molecules and the polyol molecules, forming the polyurethane polymer. As a result of this reaction, polyurethane is formed.

-

Foaming (Optional): In polyurethane foam production, a foaming process can be performed by creating a gas bubble during the reaction. This makes polyurethane foams lightweight, insulated, and flexible. The foaming process is carefully controlled to achieve the desired density and cell structure.

-

Product Processing: The polyurethane obtained after polyurethane production can be used in different forms. At this stage, the polyurethane product is shaped and processed in accordance with the desired shape, size, and properties.For example,