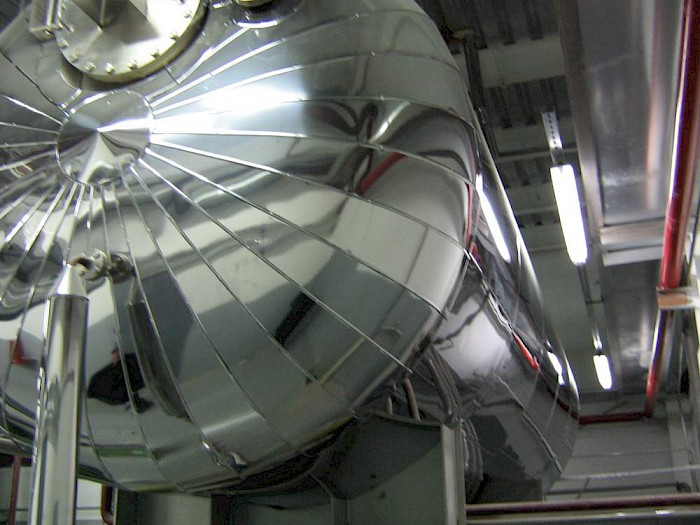

Pressure Tanks: Ensuring Safety and Efficiency in Industrial Applications

A pressure tank is a robust steel container designed to safely store liquids, gases, or vapors under pressure. These tanks play a crucial role in various industries, including:

-

Industrial manufacturing

-

Petrochemical processing

-

Energy production

-

Food and beverage processing

-

Pharmaceutical manufacturing

-

Water treatment

Key Features of Pressure Tanks:

-

Strength: Constructed from high-strength steel to withstand high internal pressures.

-

Leak-proof: Designed with a leak-proof structure to prevent hazardous spills or leaks.

-

Durability: Built to last, withstanding harsh conditions and providing a long service life.

-

Customizable: Available in various sizes, shapes, and valve/pipe configurations to meet specific needs.

Applications of Pressure Tanks:

-

Liquid and gas storage: Safe and efficient storage of various fluids under pressure.

-

Pressurized systems: Provide a consistent feed of pressurized liquids or gases to other equipment.

-

Heating and cooling systems: Used as components in heating and cooling systems.

-

Chemical reactions: Provide a controlled environment for chemical reactions under pressure.

-

Water treatment: Used in water treatment processes, such as filtration and reverse osmosis.

Pressure tanks are the ideal solution for safe and efficient storage of pressurized fluids. Their robust construction, leak-proof design, and durability make them essential in numerous industrial applications.

Types of Pressure Tanks

Pressure tanks can be categorized based on various criteria, including their intended use and technical specifications.

Classification by Area of Use:

-

Air pressure tanks: Used in air compressors and pneumatic systems.

-

Water pressure tanks: Used in water pumping systems, hydrants, and water treatment plants.

-

Fire extinguishing pressure tanks: Used in fire suppression systems.

-

Hydraulic pressure tanks: Used in hydraulic systems to store and transfer pressurized fluid.

-

Chemical pressure tanks: Designed for the safe storage and transportation of chemicals.

-

Gas pressure tanks: Used for storing and transporting various gases, including industrial gases.

-

Food pressure tanks: Used in the food industry for storing and processing liquids under pressure.

-

Pharmaceutical pressure tanks: Used in the pharmaceutical industry for storing and processing liquids.

Classification by Technical Specifications:

- Material:

-

Stainless steel pressure tanks

-

Carbon steel pressure tanks

-

- Pressure Rating:

-

Low-pressure tanks

-

High-pressure tanks

-

Pressure Tank Manufacturing Process

Manufacturing pressure tanks is a complex process that involves several crucial steps:

-

Design: The tank is designed based on its intended use, pressure rating, capacity, and other specific requirements. This stage involves determining dimensions, material selection, and other technical details.

-

Material Cutting: The tank body and components are cut to precise dimensions using advanced cutting techniques.

-

Welding: Skilled welders use specialized welding techniques to join the tank components, ensuring structural integrity and leak-proof construction.

-

Heat Treatment: In some cases, heat treatment is applied to enhance the metallurgical properties of the tank after welding.

-

Testing: Rigorous testing, including leak tests and hydrostatic pressure tests, ensures the tank's safety and performance under pressure.

-

Painting and Coating: Protective coatings are applied to prevent corrosion and ensure longevity.

-

Assembly: Valves, fittings, and other accessories are installed on the tank.

-

Inspection: The finished pressure tank undergoes inspection by an authorized body to ensure compliance with safety standards and regulations.

Key Techniques Used in Pressure Tank Manufacturing:

-

Welding: TIG, MIG, MAG, and SMAW welding methods are commonly used.

-

Heat Treatment: Annealing, tempering, and hardening techniques may be employed.

-

Testing: Leak testing, hydraulic testing, and burst testing are performed to ensure safety and reliability.

Partner with Aces Process for Pressure Tank Solutions

By working with Aces Process, you can ensure the safety of your operations and increase productivity. Contact us today to receive a customized solution for your pressure tank needs. Our expert engineers and technicians are ready to assist you with your project requirements.

Learn More

Visit our page to learn more about Aces Process Storage Stock Tanks.

Pressure Tank Safety

Pressure tank safety is important due to the potential hazards associated with pressurized equipment.

Ensuring Pressure Tank Safety:

-

Design and Manufacturing:

-

Compliance with relevant regulations and standards.

-

Selection of appropriate materials for the intended use and operating conditions.

-

Welding performed by qualified welders.

-

Robust and leak-proof construction of all components and connections.

-

-

Usage:

-

Adherence to operating instructions.

-

Operation within specified pressure and temperature limits.

-

Regular maintenance and inspections.

-

Immediate removal from service and reporting of any malfunctions or damage.

-

-

Safety Precautions:

-

Secure placement of the tank in a safe area.

-

Sufficient working space around the tank.

-

Installation of necessary safety equipment (safety valves, pressure gauges).

-

Proper training of personnel on pressure tank safety.

-

Here are some safety tips for using pressure tanks:

-

Read and follow the manufacturer's instructions.

-

Never exceed the maximum pressure rating of the tank.

-

Inspect the tank regularly for signs of damage.

-

Keep the tank in a safe location away from heat, sparks, and flammable materials.

-

Use the proper safety equipment when working with pressure tanks.

By following these safety tips, you can help to ensure that your pressure tank is used safely and efficiently.

Additional tips:

-

Get trained in pressure tank safety.

-

Follow all local, state, and federal regulations.

-

Use only approved pressure tanks.

-

Never tamper with the safety devices on a pressure tank.

Conclusion

Pressure tanks are a valuable tool in many industries. However, they can be dangerous if they are not used properly. By following the safety tips in this video, you can help to ensure that your pressure tank is used safely and efficiently.

Relevant Regulations and Standards:

-

TS EN 13445:2014 Pressure vessels - Cylindrical storage vessels - Design and manufacturing

-

TS ISO 28590:2010 Pressure vessels - General requirements for steel pressure vessels

-

Pressure Vessels Periodic Control Regulation