What is a Pressure Vessel?

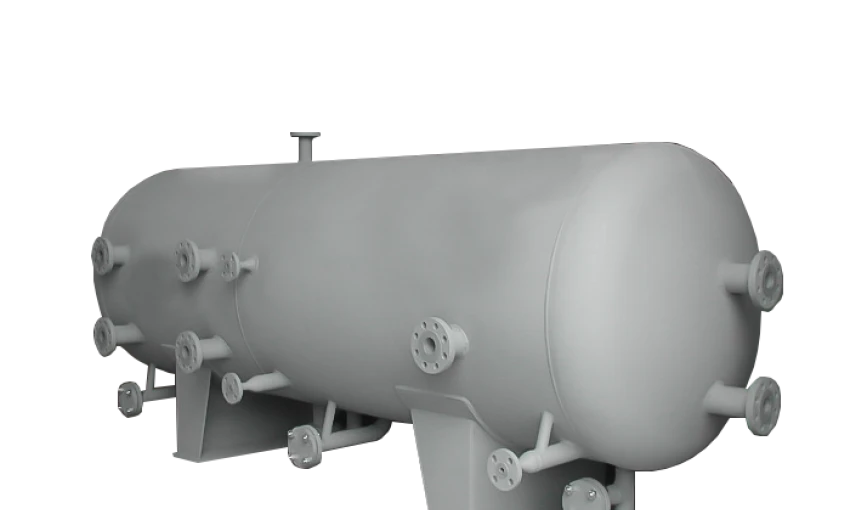

Pressure vessels are robust and durable structures designed to hold gases or liquids at a pressure significantly higher than the ambient atmospheric pressure. Widely utilized in industrial and medical applications, pressure vessels ensure the safe and efficient storage and transportation of various gases and liquids.

The design and manufacturing of pressure vessels require meticulous attention to detail and expertise due to the high pressures they contain. These vessels are strictly regulated by international and local regulations to ensure their safe and reliable operation.

Pressure Vessel Manufacturing

At Aces Process, we provide customized pressure vessel solutions that combine safety and efficiency. We specialize in manufacturing pressure vessels, pressure tanks, pressure boilers, and other similar equipment.

Our experienced engineers and expert team work meticulously to meet the unique needs of each client. Our manufacturing process is supported by state-of-the-art equipment and stringent quality controls. This ensures that each pressure vessel meets the highest standards of durability, safety, and performance.

Pressure Vessel Design

In the design phase of pressure vessels, priority should be given to safety and material selection.

Safety involves designing the vessels to withstand factors such as the specified operating pressure and temperature. An incorrectly designed or poorly manufactured pressure vessel can lead to serious hazards.

The material to be used in the manufacture of pressure vessels should be determined according to the properties of the substance to be stored in the vessel, the pressure and temperature conditions, and chemical compatibility.

Advantages Offered by Aces Process:

Reliable Products:

-

Durable and long-lasting pressure vessels

-

Manufacturing in compliance with the highest safety standards

-

Efficient and high-performance pressure vessels

Customized Solutions:

-

Solutions tailored to the specific needs of the client

-

Wide range of pressure vessel capacities and designs

Expertise and Quality:

-

Experienced engineers and expert team

-

Reliable products with strict quality controls

-

Periodic inspection services

With Aces Process:

-

Meet the needs of your business

-

Achieve a safe and efficient production process

-

Have long-lasting and high-performance pressure vessels

Contact us now, and let's find the most suitable pressure vessel solution for you!

Periodic Inspections of Pressure Vessels

Periodic inspections aim to assess the strength, integrity, and functionality of pressure tanks.

Periodic inspections may include various methods such as visual inspection, pressure tests, and non-destructive tests.

-

Visual inspection: Involves examining the external surface of the tank and connection points for physical damage, corrosion, or wear.

-

Pressure tests: Evaluate the tank's durability and leak-tightness by subjecting it to a certain pressure.

-

Non-destructive tests: Utilize methods such as ultrasound, magnetic particle testing, or radiography to assess the internal structure and material quality of the tank.

The purpose of periodic inspections is to identify and prevent potential hazards, reduce the risk of failure, and ensure the safe and reliable operation of the tank. These inspections enable the early detection of deformations or weaknesses that may occur due to the aging, wear, and environmental effects on the tank.

What are the Different Types of Pressure Vessels?

Pressure vessels can be of different types depending on their usage areas and functions. Here are some common types of pressure vessels:

-

Pressure Tanks: These are vessels used to store gas or liquid. Examples include fuel storage tanks, air compressor tanks, and chemical storage tanks.

-

Pressure Containers: These are typically cylindrical vessels used to store or transport gases. Containers for storing and transporting industrial gases such as oxygen, nitrogen, hydrogen, and argon fall into this category.

-

Pressure Boilers: Used for thermal energy production, these vessels generate energy by keeping water vapor or heated liquid under high pressure. Examples include steam boilers, water heaters, and steam generators.

-

Pressure Reactors: Reactors used in chemical processes operate under pressure to carry out chemical reactions under controlled conditions.

What are the Industries Where Pressure Vessels are Used?

Pressure vessels are widely used in many industries. Here are some industry examples:

-

Oil and Gas Industry: Pressure vessels are commonly used in facilities such as oil refineries, natural gas processing plants, and oil drilling. Storage tanks, pressure pipes, gas cylinders, and pressure reactors are frequently used vessels in this industry.

-

Chemical Industry: Chemical production plants, laboratories, and research centers use pressure vessels. Chemical reactors, pressure tanks, boilers, and tubes play an important role in chemical processes.

-

Power Generation Plants: Pressure vessels are used in power generation facilities such as power plants, thermal power plants, and nuclear power plants. Steam boilers, turbines, and pressure cylinders are an important part of energy conversion and transmission.

-

Food and Beverage Industry: Pressure vessels are used in food processing and beverage production facilities. Fermentation tanks, pasteurization equipment, carbonization systems, and pressure cylinders are an indispensable part of this industry.

-

Automotive Industry: Pressure vessels are used in automotive production facilities in compressed air systems, paint spraying equipment, and hydraulic systems.

-

Pharmaceutical Industry: Pressure vessels such as sterilization equipment, fermentation tanks, and pressure reactors are used in pharmaceutical production facilities.

What is a Simple Pressure Vessel?

Simple pressure vessels are part of many pieces of equipment frequently encountered in daily life. They operate within a certain pressure range to ensure the safe storage or transport of gases or liquids. Since they are generally used in low-risk applications, they have less complex designs and less demanding safety requirements. Tanks that do not come into contact with fire, with an internal pressure higher than 0.5 bar but a maximum operating pressure not exceeding 30 bar, fall within the scope of simple pressure vessels.

What Should the Pressure of a Pressure Vessel Be?

The operating pressure of pressure vessels varies depending on the intended use, design, and application area. The minimum requirements for pressure vessels to withstand a certain pressure are determined by design and manufacturing standards. Therefore, when it comes to the design or use of a specific pressure vessel, the specific requirements specified in the relevant design standards and local regulations should be consulted.

Is a Hydrophore a Pressure Vessel?

Yes, hydrophores are considered pressure vessels. Since hydrophores are a system that includes a pressure vessel, it is important to comply with relevant standards and safety regulations during the design and manufacturing phase. The pressure vessel in the system must be made of pressure-resistant materials and tested according to specific pressure values.

Is an Autoclave a Pressure Vessel?

Yes, autoclaves are considered pressure vessels. Since autoclaves are considered pressure vessels, their design and manufacture must be carried out in accordance with relevant industry standards, regulations, and safety requirements.

Are Cryogenic Tanks Pressurized?

Yes, cryogenic tanks fall into the category of pressure vessels. Cryogenic tanks are closed systems designed for the storage and transport of liquefied gases at low temperatures. Since cryogenic tanks are considered pressure vessels, their design, production, and use must be carried out in accordance with relevant industry standards, regulations, and safety requirements. In addition, periodic maintenance, inspections, and regular assessment of insulation performance are important.

What is the Periodic Inspection Period for Pressure Vessels?

The periodic inspection period for pressure vessels varies depending on the type of vessel used, design features, intended use, local regulations, and standards. In many industries, specific intervals are set for the periodic inspection of pressure vessels. In general, it is recommended that pressure tanks be inspected annually, but in some countries and sectors, this period can be extended up to 5 years.

What is the Simple Pressure Vessels Regulation?

SIMPLE PRESSURE VESSELS DIRECTIVE (2014/29/EU)

It is a regulation in Turkey that covers simple pressure vessels. This regulation sets out the minimum safety requirements for the design, manufacture, and free movement of pressure vessels.