Ribbon Mixers: The Ultimate Guide to Efficient Industrial Mixing

Unlock the Power of Homogeneous Mixing with Aces Process Ribbon Mixers

Aces Process is a leading provider of industrial mixing solutions, specializing in high-quality ribbon mixers. Our meticulous craftsmanship and innovative approach ensure that your ribbon mixer delivers exceptional performance, efficiently blending materials across diverse sectors.

Equipped with high-performance motors and specialized designs, Aces Process ribbon mixers provide superior mixing capabilities, effortlessly handling even tough and sticky materials.

With a customer-centric approach, we offer ribbon mixers in various sizes and capacities to meet the unique needs of every business. We also provide custom-designed ribbon mixers to fulfill your specific requirements.

Key Features of Aces Process Ribbon Mixers:

-

High Performance: Powerful motors effortlessly handle even the most challenging materials.

-

Homogeneous Mixing: Specially designed blades ensure perfect mixing homogeneity.

-

Fast Processing: Achieve high efficiency and rapid mixing in a short time.

-

Durability: Constructed from robust and durable materials for long-lasting performance.

-

Easy Cleaning: Practical and quick cleaning with easily detachable parts.

Contact us to receive a customized ribbon mixer design and price quote tailored to your business needs.

Learn more about our comprehensive range of Industrial Mixers on our dedicated page.

What are Ribbon Mixers?

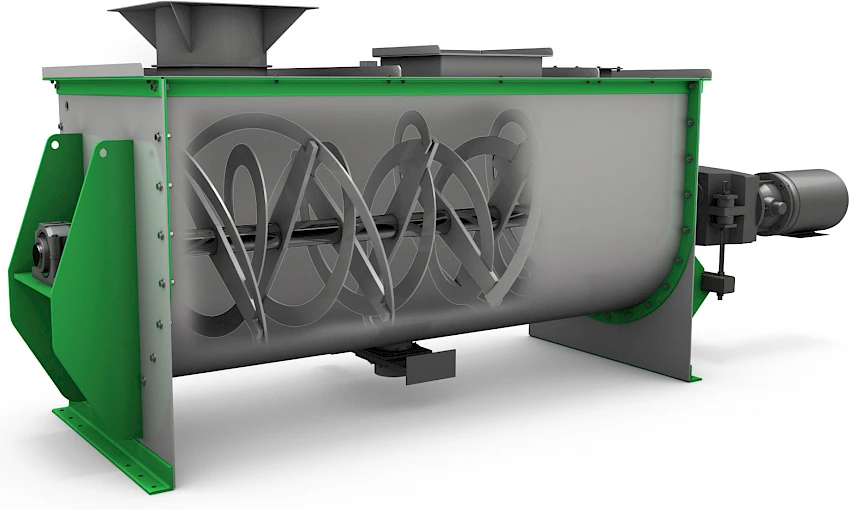

Ribbon mixers are specialized mixing equipment featuring two helical mixing blades that rotate in opposite directions within a U-shaped trough. This design ensures thorough and efficient mixing of a wide range of materials, particularly powders and granules.

How Do Ribbon Mixers Work?

The counter-rotating helical blades create a fluidizing action, lifting and tumbling materials to achieve a homogenous mixture. This mechanism effectively handles even sticky and difficult-to-mix materials.

Applications of Ribbon Mixers:

Ribbon mixers are widely used in various industries, including:

-

Food: Mixing ingredients for bakery products, confectionery, spices, nuts, and more.

-

Chemicals: Blending powders, granules, and pastes for paints, coatings, plastics, detergents, and other chemical products.

-

Pharmaceuticals: Mixing powders and granules for pharmaceuticals, cosmetics, and nutraceuticals.

-

Other Industries: Used in various sectors, including agriculture, construction, and plastics.

Ribbon Mixer Manufacturing Process:

Aces Process follows a meticulous manufacturing process to ensure the highest quality and performance:

-

Design: We carefully analyze your requirements to determine the optimal dimensions, geometric design, and technical features of the mixer.

-

Material Selection: We utilize durable and corrosion-resistant materials, such as stainless steel, for the mixer body, shaft, and blades.

-

Cutting and Processing: Advanced techniques like laser cutting, bending, and welding are employed to manufacture the mixer components with precision.

-

Assembly: All parts are meticulously assembled to ensure proper alignment and functionality.

-

Testing and Quality Control: Rigorous testing and quality control procedures are implemented to verify the performance and reliability of the mixer.

Frequently Asked Questions About Ribbon Mixers

-

In which sectors are ribbon mixers used?

Ribbon mixers find applications in a wide range of industries, including:

-

Food: Bakery products, confectionery, spices, nuts, flour, sugar, etc.

-

Chemicals: Paints, coatings, plastics, detergents, pigments, chemical powders, fertilizers, etc.

-

Pharmaceuticals: Tablets, capsules, pharmaceutical raw materials, cosmetic products, etc.

-

Mining: Metal powders, mineral powders, lime, sand, cement, etc.

-

Plastics: Plastic raw materials, granules, powders, and additives.

What materials are ribbon mixers used to mix?

Ribbon mixers excel at mixing sticky, viscous, and hard materials. They are particularly effective for blending powders, granules, and pastes, even those with challenging flow properties.

-

How do ribbon mixers work?

Ribbon mixers utilize two helical blades that rotate in opposite directions, creating a fluidizing action that lifts and folds the material to achieve a homogeneous mixture.

-

What is the capacity of ribbon mixers?

Ribbon mixers are available in various sizes and capacities, ranging from 50 liters to 20,000 liters, to accommodate different production needs.

-

How to clean ribbon mixers?

Cleaning methods vary depending on the materials processed. Generally, hot water and detergent are used, and in some cases, specialized cleaning solutions may be required.

-

How durable are ribbon mixers?

Aces Process ribbon mixers are manufactured from high-quality materials, ensuring durability and longevity. However, the lifespan can vary depending on the materials used, maintenance practices, and operating conditions.

-

How to buy ribbon mixers?

When purchasing a ribbon mixer, consider factors such as capacity, material properties, frequency of use, manufacturer experience, and customer service. Aces Process offers customized ribbon mixers tailored to your specific needs. Review the warranty and service options before making a purchase.

-

What is the difference between ribbon mixers and other mixing equipment?

Ribbon mixers offer faster and more homogeneous mixing compared to other types of mixers, especially for sticky and viscous materials. Their helical blades allow for adaptable mixing action based on material characteristics.

-

How much do ribbon mixers cost?

The price of a ribbon mixer depends on factors such as capacity, material properties, and manufacturer quality.

-

Can special orders be placed for ribbon mixers?

Yes, Aces Process can manufacture customized ribbon mixers tailored to your specific requirements, including material specifications, production processes, and product quality.