Shell and Tube Heat Exchanger Prices

Shell and Tube Heat Exchangers: Inspiring Future Technological Advancements

In this article, we delve into shell and tube heat exchangers, pushing the boundaries of engineering, and explore their limitless potential and unique features. We'll also examine how they inspire future technological advancements with their industrial advantages.

Shell and tube heat exchangers hold a significant place in the engineering world. Aces Process stands out as a leading company in the sector with its superior capabilities in the design, manufacturing, and installation of shell and tube heat exchangers. Aces Process's engineers and technicians demonstrate their perfectionism and expertise while creating innovative designs for these exchangers.

Efficient Heat Transfer

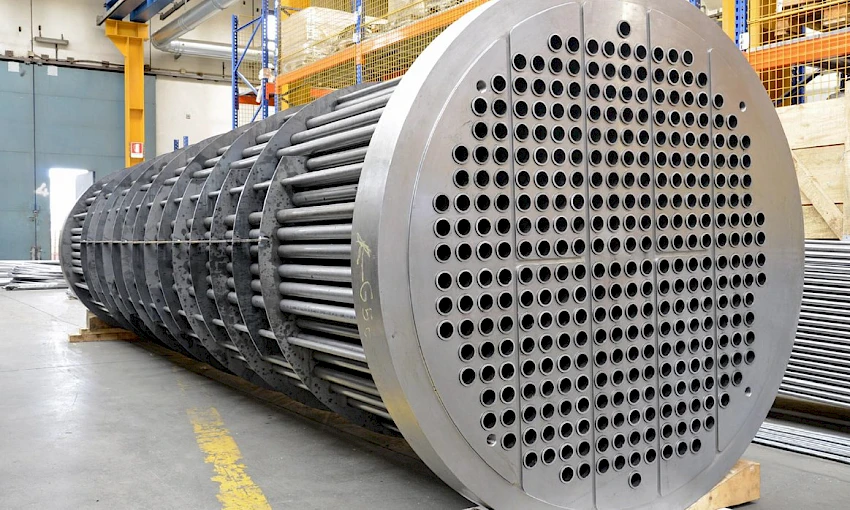

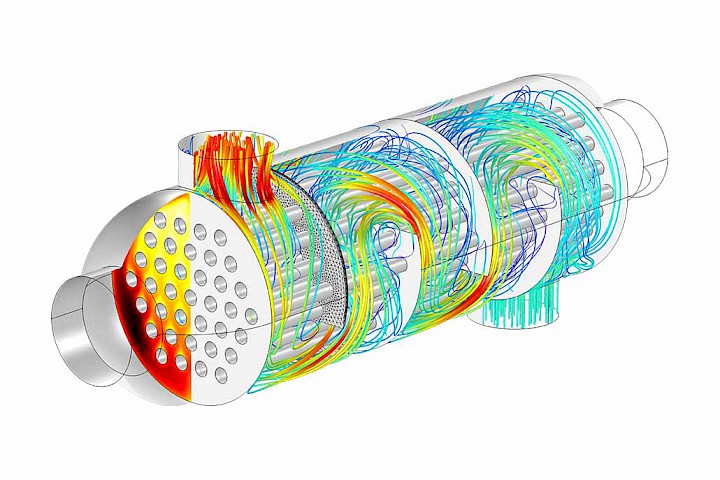

Shell and tube heat exchangers have a special design that provides efficient heat transfer. Their structure, consisting of tube bundles, ensures effective heat transfer while maintaining durability even under high temperatures and pressures. It wouldn't be wrong to say that these exchangers are ideal for many industrial applications.

Meticulous Design by Aces Process Engineers

Aces Process's engineers and technicians take great care in designing shell and tube heat exchangers. They offer customized solutions for each project and develop the best design to fully meet customer needs.

Wide Range of Applications

The application areas of shell and tube heat exchangers are quite extensive. They are used in many industries, such as chemical, petrochemical, energy, food, and automotive. They also attract attention with their environmentally friendly designs. With their sustainability-focused approach, Aces Process engineers design exchangers that increase energy efficiency and minimize waste generation.

Shaping Future Technological Advancements

There is no doubt that shell and tube heat exchangers will shape technological advancements in the future. These exchangers continuously demonstrate innovation in areas such as the use of new materials, increased efficiency, and digitalization. Aces Process closely follows these technological developments to maintain its leading position in the sector and continuously improves its designs.

Conclusion

The exciting world of shell and tube heat exchangers pushes the boundaries of science and engineering and inspires future technological advancements. Aces Process's engineers and technicians stand out in the sector with their superior capabilities in the design, manufacturing, and installation of shell and tube heat exchangers. The unique features, industrial advantages, and wide application areas of these exchangers make them indispensable components. Shell and tube heat exchangers will contribute to Aces Process maintaining its leadership position and shaping future technological developments.

Shell and Tube Heat Exchangers: Heat Transfer Technology Reaching into the Future

Touch the Future of Engineering Marvels with Aces Process!

Shell and tube heat exchangers offer innovative solutions that push the boundaries of engineering and carry heat transfer technology into the future. Aces Process, with its leadership in this field, continues to inspire the sector.

Why Aces Process Shell and Tube Heat Exchangers?

-

Perfectionist Design: Our expert engineers and technicians design customized, high-performance, and durable exchangers for each project.

-

Unlimited Potential: We offer a wide range of products that meet the needs of different sectors.

-

Unique Features: We manufacture exchangers that are resistant to high temperatures and pressures, provide efficient heat transfer, and have a long service life.

-

Industrial Advantages: We offer energy savings, increased production efficiency, and environmentally friendly solutions.

-

Inspiring the Future: We push the boundaries of heat transfer technology with innovative R&D efforts.

Aces Process Shell and Tube Heat Exchangers:

-

Chemical Industry: For heat transfer in processes such as reactions, distillation, and crystallization.

-

Petrochemical Industry: For heat recovery in refineries and crude oil processing plants.

-

Energy Sector: For heat transfer in thermal power plants and other energy production facilities.

-

Food Sector: For heat transfer in processes such as pasteurization, sterilization, and concentration.

-

Pharmaceutical Sector: For heat transfer and cooling in pharmaceutical production facilities.