Types of Mixers - Mixers and Reactors

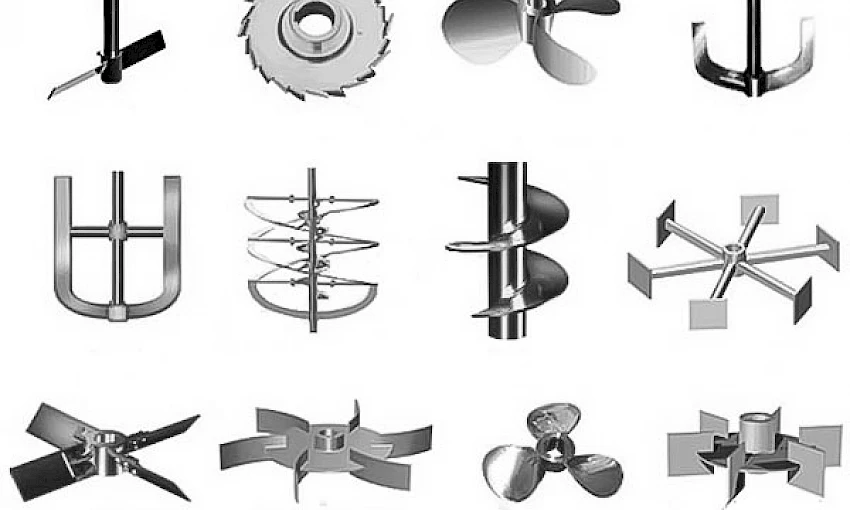

Propeller Type Mixer

Propeller type mixers utilize propellers that rotate the materials to be mixed around a central axis. This type of mixer is commonly used for the homogeneous mixing of liquids and is generally effective for low-viscosity liquids.

Helical Type Mixer

Helical type mixers mix materials by rotating them around a shaft or helix. This design is often used to ensure homogeneous mixing of materials and is ideal for thickening processes.

Turbine Type Mixer

Turbine type mixers utilize turbines with wide blades that can operate at high speeds. This provides a rapid effect on the mixing process and is preferred for mixing materials with high viscosity values.

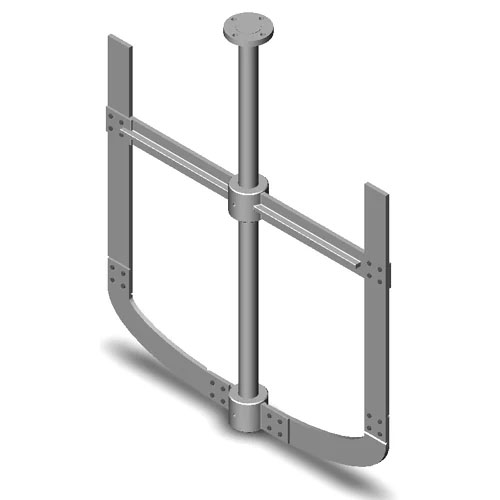

Anchor Type Mixer

Anchor type mixers perform the mixing process using rotating anchors with large blades. They are generally used in high-volume mixing operations.

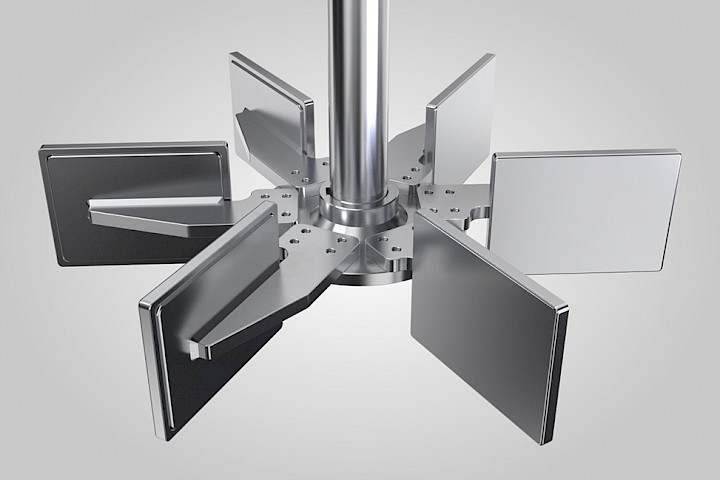

Blade Type Mixer

Blade type mixers are designed to intensively disperse materials thanks to their special shapes. They are used in applications requiring intensive dispersion and ensure homogeneous mixing of materials.

Disperser Type Mixer (High-Speed Mixer)

Disperser type mixers are equipped with rotors that can operate at high speeds. This is ideal for dispersing and mixing high-viscosity materials and is used to accelerate chemical reactions.

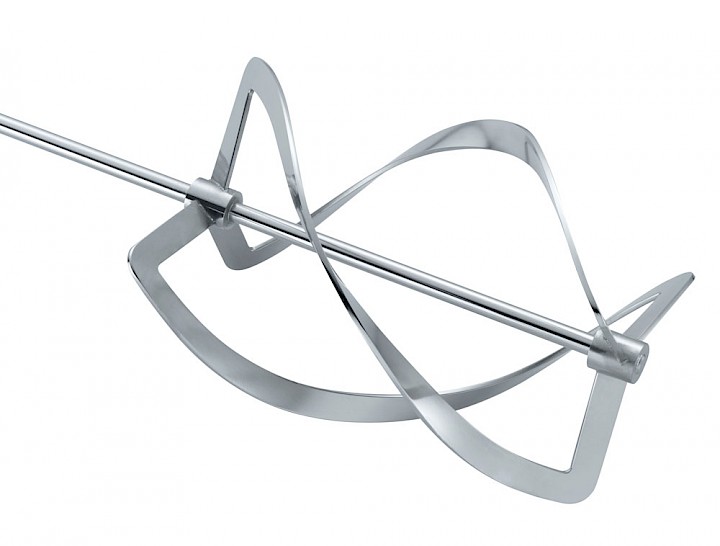

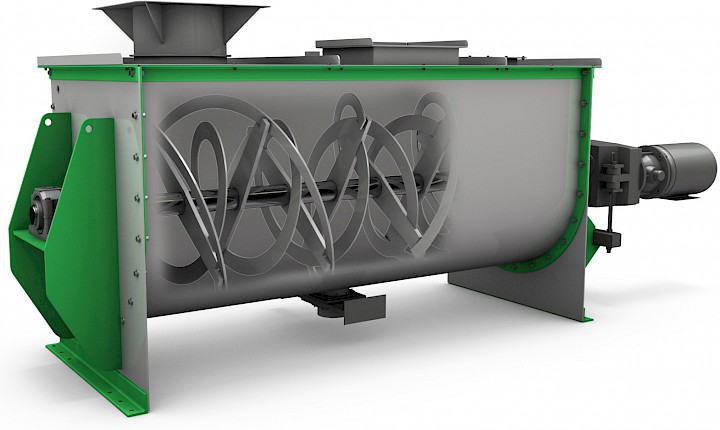

Ribbon Type Mixer

Ribbon type mixers gradually mix materials thanks to their special design. They are generally used to achieve a homogeneous mixture.

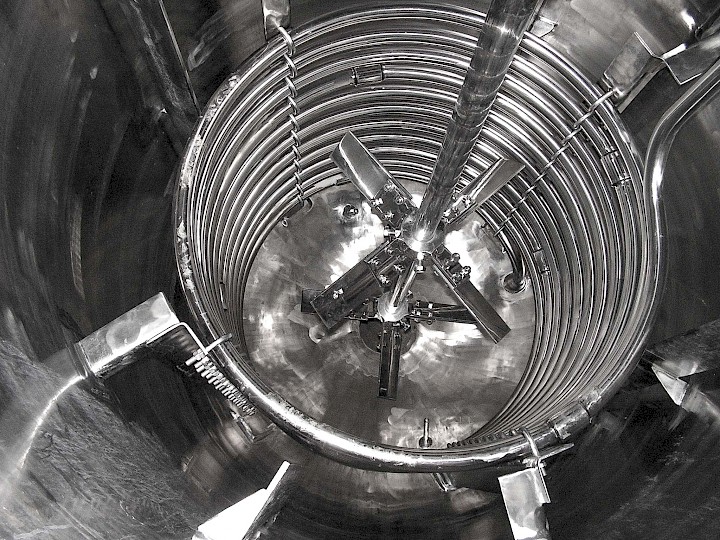

What is a mixer agitatör?

Mixers are industrial machines used to homogeneously mix, disperse, dissolve, or promote reactions of liquids or semi-solid substances. They typically consist of an assembly that includes a shaft and a mixing blade located at the end of the shaft. The shaft is connected to a gearbox or drive mechanism and is rotated by electrically powered motors.

Mixers have a variety of applications, and their functions range from homogenizing the mixture to accelerating chemical reactions, mixing liquids and gases, and transferring heat. These machines are used in industrial processes and laboratory work.

Industries and Applications Where Mixers are Used

Mixers are widely used in many industries and applications. Here are examples of some of the main industries and applications where mixers are used:

Chemical Industry:

-

Initiating and maintaining chemical reactions.

-

Homogeneous mixing of chemical components.

-

Polymer production.

-

Acid-base neutralization processes.

Food and Beverage Industry:

-

Mixing food and beverage products.

-

Production of sauces, creams, and mayonnaise.

-

Pastry and bread production.

-

Sugar melting and mixing processes.

Pharmaceutical and Cosmetic Industry:

-

Homogeneous mixing of pharmaceutical raw materials.

-

Production of creams, lotions, and other cosmetic products.

-

Mixing and granulation of pharmaceutical tablets.

Oil and Petrochemical Industry:

-

Petrochemical processes in oil refineries.

-

Mixing and separating petroleum products.

-

Gas desulfurization processes.

Environmental Engineering:

-

Chemical dosing and mixing in wastewater treatment plants.

Paper and Pulp Industry:

-

Pulp mixing and bleaching processes.

-

Preparation of paper pulp.

-

Ink production.

These are just a few examples, and mixers are used in a wide variety of industries and applications. Each application may require different types of mixers depending on specific requirements and process needs.

Mixer Reactors

Mixer