Welding Methods and Technologies: TIG/Argon and MIG/MAG

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. This is a fundamental joining technique used across a wide range of industries and applications, from manufacturing and repair to construction.

Welding Methods

There are various welding methods and technologies available, each with its own advantages and disadvantages. Some of the most common welding methods include:

-

Shielded Metal Arc Welding (SMAW): This is one of the oldest and most common types of welding. SMAW uses an electrode to create an electric arc that melts the metal pieces together.

-

Gas Metal Arc Welding (GMAW) / MIG (Metal Inert Gas): In this method, a welding gun is used to create an electric arc that melts the metal pieces together. The arc is shielded by an inert gas. This is a fast and efficient welding method.

-

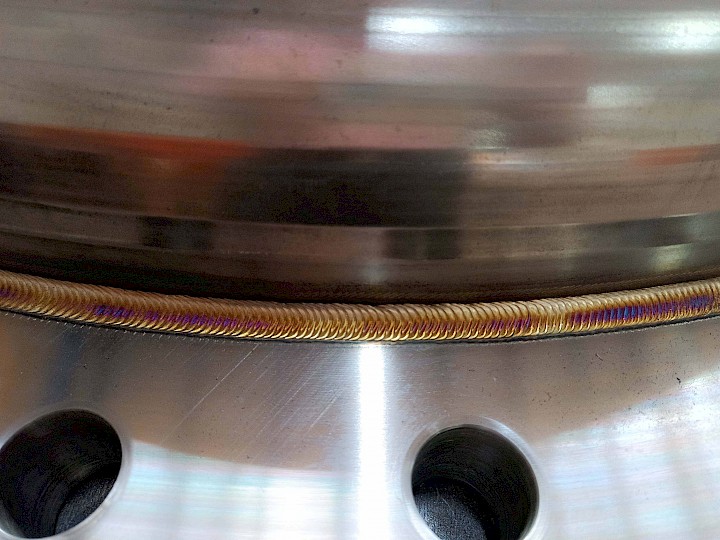

Gas Tungsten Arc Welding (GTAW) / TIG (Tungsten Inert Gas): This method uses a tungsten electrode to create an electric arc that melts the metal pieces together. The arc is shielded by an inert gas. This method is known for producing high-quality and precise welds.

-

Plasma Arc Welding (PAW): This method uses plasma to melt the metal pieces together. Plasma is a high-temperature gas.

Welding Technologies

Welding technologies are constantly evolving. New technologies allow for faster, more efficient, and higher quality welding. Some of the latest welding technologies include:

-

Laser Beam Welding (LBW): This method uses a laser beam to melt the metal pieces together. Laser welding offers high precision and deep penetration.

-

Electron Beam Welding (EBW): This method uses a high-energy electron beam to melt the metal pieces together. Electron beam welding provides high penetration and low heat input.

-

Ultrasonic Welding (USW): This method uses ultrasonic vibrations to join the metal pieces together. Ultrasonic welding is ideal for delicate parts.

Choosing the Right Welding Technology

The selection of the right welding method and technology depends on a number of factors, including:

-

Type of material

-

Thickness of the parts

-

Weld geometry

-

Required weld quality

-

Cost considerations

Aces Process Welding Solutions

Aces Process specializes in various welding methods and technologies. With our expert team and modern equipment, we offer solutions for all your welding needs. Whether you require TIG/argon or MIG/MAG welding, we can deliver precise, durable, and high-quality welds that meet the demands of your project.

Further Information

To further enhance this article and provide more value to readers, you could consider adding the following:

-

Images and Diagrams: Visual aids can greatly improve understanding of different welding methods and technologies.

-

Specific Applications: Provide examples of how each welding method is used in different industries.

-

Advantages and Disadvantages: Discuss the pros and cons of each welding method to help readers make informed decisions.

-

Safety Considerations: Highlight the importance of safety precautions in welding operations.

-

Quality Control: Explain the quality control measures employed by Aces Process to ensure weld integrity and reliability.