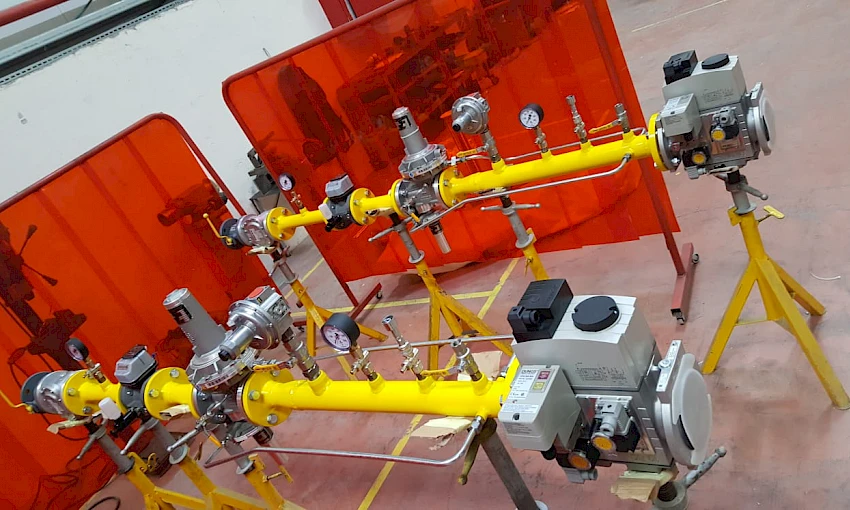

Gas Train System : Fabrication & Design & Assembly

Welcome to the official website of ACES PROCESS Company, a leading provider of cutting-edge solutions in the production and design of Gas Train Systems. We specialize in creating custom gas train systems that ensure the safe, efficient, and reliable operation of industrial processes. Whether you're looking to upgrade your existing gas train or require a brand-new, tailor-made system, ACES Company is your trusted partner in optimizing gas delivery for industrial applications.

Importance of Gas Transfer Systems

Gas transfer systems are critical components of any gas-fired heating or combustion system. They are responsible for safely delivering fuel gas to the burner or combustion chamber while controlling the gas flow rate and pressure.

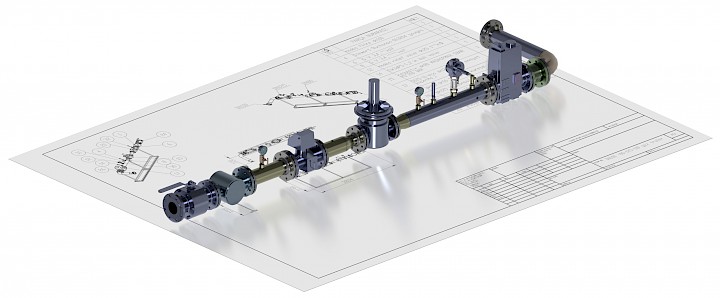

Components of a Gas Transfer System

A gas line system typically includes a range of components, such as gas pressure regulators, safety shut-off valves,pressure switches, and gas filters. The configuration of the gas line can vary depending on the specific application, but the primary goal is to ensure the safe and reliable delivery of gas to the burner.

Gas Pressure Regulators: Ensuring Safe and Efficient Operation

One of the critical components of a gas transfer system is the gas pressure regulator. This device is responsible for controlling the pressure of the gas supplied to the burner. The regulator ensures that the gas pressure is consistent and within the required range for the burner to operate safely and efficiently. There are different types of gas pressure regulators available, including direct-acting, pilot-operated, and servo-controlled regulators, each designed for specific applications.

Safety Shut-off Valves: Protecting Against Gas Leaks

Another important component of a gas transfer system is the safety shut-off valve. This valve is designed to automatically shut off the gas supply to the burner in the event of a gas leak or other safety hazard. The safety shut-off valve is typically controlled by a pressure switch that detects abnormal gas pressure conditions and triggers the valve to close.

Gas Filters: Maintaining Clean Fuel Supply

The gas transfer system also includes gas filters designed to remove dirt or debris from the gas source. These filters help protect the burner and other components of the gas transfer system from damage by ensuring the gas is clean and free of contaminants.

Conclusion

In summary, gas transfer systems play a critical role in ensuring the safe and reliable operation of gas-fueled heating and combustion systems. By controlling the flow rate and pressure of the gas and incorporating safety features like shut-off valves and pressure switches, gas transfer systems help prevent accidents and ensure these systems operate efficiently.

Call to Action

Gas Control Line

Gas control lines ensure efficient burner operation. They are designed to monitor pressure, detect leaks and intervene in emergency situations.

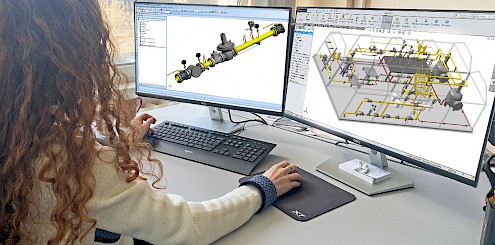

As ACES engineers, we are inspired by the revolutionary impact of machines in industrial processes and are dedicated to continuously developing new processes and machines to provide lasting support to our customers. We prioritize customer satisfaction, aiming to make our clients more competitive and to be a partner in their success.

Contact

Phone : +90 536 233 30 76

Email : [email protected]

Address

Address : Ovacık Mah. Mimar Sokak No:10

Başiskele / KOCAELİ / TÜRKİYE