Tube Heat Exchanger

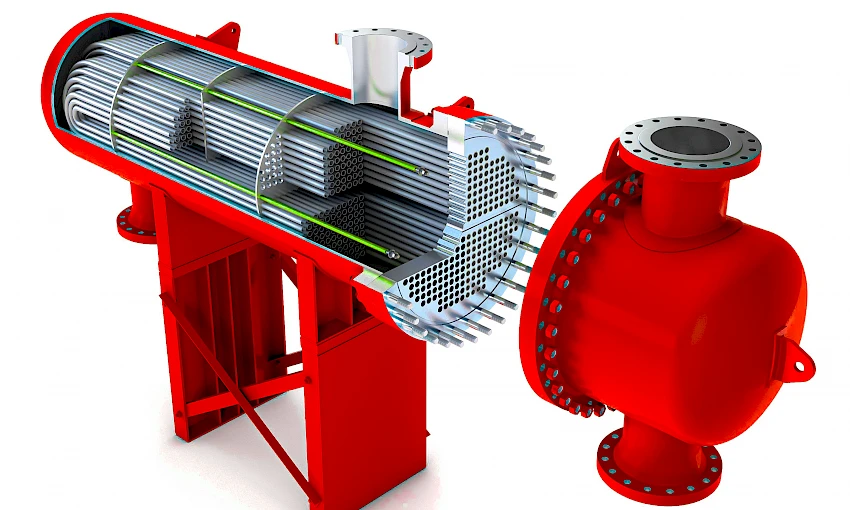

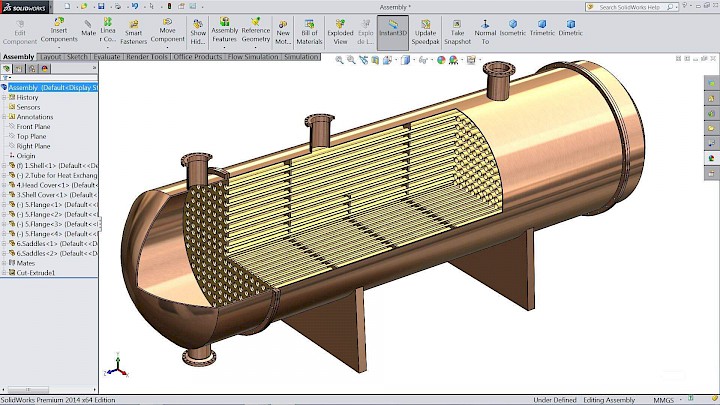

This is the most durable and efficient type of heat exchanger that enables heat transfer between two fluids at different temperatures without mixing them in industrial facilities. Known in engineering literature as “shell-and-tube heat exchangers,” these systems consist of bundles of tubes placed inside an outer shell.

How Does a Tube Heat Exchanger Work?

The basic operating principle is based on the transfer of heat from a high-temperature fluid to a low-temperature fluid through metal pipe walls. Thanks to their high pressure and temperature resistance, pipe heat exchangers play a critical role in the petrochemical, power plant, and food industries, minimizing operating costs by increasing energy efficiency. Designed in accordance with TEMA standards, this equipment offers maximum thermal performance through LMTD (Logarithmic Temperature Difference) optimization.

How to Calculate a Tube Heat Exchanger?

Pipe heat exchanger calculation is the art of establishing a balance between how much heat the exchanger will transfer and how much energy the fluids will lose as they pass through the system. In our engineering department, these calculations are usually performed using the “Kern Method” or the “Bell-Delaware” Method.

-

Determination of Heat Load (Q): The first step in the calculation is to determine how much heat the system needs to transfer. In the calculation we mentioned, this is calculated using the mass flow rate, specific heat, and temperature difference of the fluid.

-

Logarithmic Temperature Difference (LMTD) Calculation: It is the average temperature difference representing the driving force between fluids. This calculation is performed to determine the difference in a counterflow system.

-

Estimation of the Overall Heat Transfer Coefficient (U): The U-value in the heat exchanger calculation tests how easily heat can transfer from one fluid to another. You can think of it as a heat transfer rating. The higher this rating, the more efficiently your heat exchanger will operate. The heat transfer coefficient is the most critical variable in determining the size of the heat exchanger. As the U-value increases, the size and cost of the heat exchanger required to perform the same task decrease.

-

Calculation of the Required Heat Transfer Area (A): Once the thermal load and U-value are known, the required surface area is determined.

-

Number of Pipes and Geometric Design: You can think of this stage as the section where we assemble the puzzle pieces into a whole after all the complex calculations. After calculating the total area (A) required, we need to fit this area into a physical body, meaning we decide how many pipes to use, how long these pipes will be, and how wide their diameters will be. Our design process continues until we find that perfect balance that transfers heat exactly as we want it to while not restricting flow.

Tube Heat Exchanger Manufacturing

• Material Selection and Design Preparation: Metals such as carbon steel, stainless steel, or copper, selected according to design calculations, are procured. The sheets to be used for the shell and the seamless pipes required for the tube bundle undergo quality control.

•Shell Manufacturing: To form the cylindrical shell, sheets are bent on cylindrical machines and joined by longitudinal welding. Fluid inlet and outlet nozzles (connection ports) and transport handles are welded onto the shell.

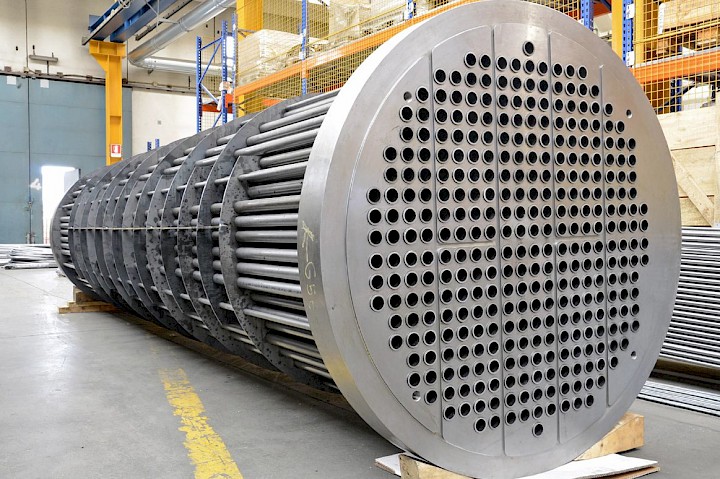

•Tube Sheet Processing: The tube sheets, which are the main plates to which the tubes are attached, are drilled with high precision on CNC machines.

•Bundle Formation: The baffle plates and tube sheets are arranged on a skeleton. Then, hundreds, sometimes thousands of tubes are passed through these holes to form a bundle.

•Fixing the Tubes to the Tube Sheet: Securing the tubes to the tube sheet in a leak-proof manner is the most critical step. The tube ends are usually expanded by machining and pressed into the tube sheet or fixed with leak-proof welding.

•Assembly and Joining: The prepared tube bundle is placed inside the cylindrical shell. Covers and leak-proof gaskets are installed to complete the main structure of the exchanger.

•Testing and Quality Control: At the end of manufacturing, the device is subjected to a hydrostatic test (pressure test). The pipe side and body side are tested separately to check for leaks. Non-destructive testing (X-ray or liquid penetrant testing) is also performed on the welds. At Aces Process, we combine internationally certified welding technologies and rigorous quality control processes in accordance with TEMA/ASME standards in the manufacture of tube heat exchangers, ensuring the highest level of industrial safety.

Tube Heat Exchanger Features

•High Pressure and Temperature Resistance: We offer rigid designs that maintain structural integrity under extreme temperature and pressure values in the most demanding industrial conditions.

•Wide Range of Materials: We provide expert craftsmanship from carbon steel to stainless steel, and even special alloys such as titanium, depending on fluid characteristics and corrosion risk.

•Manufacturing to TEMA and ASME Standards: We deliver international reliability by ensuring our designs are fully compliant with globally recognized standards.

•Maximum Thermal Efficiency: We aim for the highest heat transfer coefficient (U) by increasing turbulence with precisely calculated baffle plate arrangements and pipe pitches.

•Zero-Defect Welding Quality: We guarantee leak-tightness in tube-to-shell joints using certified welding methods and NDT (X-ray, penetrant) testing.

•Ease of Maintenance and Cleaning: We implement modular designs that allow the tube bundle to be easily disassembled, cleaned, and serviced for operational continuity.

Tube Heat Exchanger Applications

•Petrochemicals and Refineries: Ensures safe heat control for high-temperature chemical processes and crude oil.

•Power Plants: Serves as a condenser and feedwater heater in high-pressure steam cycles.

• Food and Beverage Industry: Provides hygienic and precise temperature management in thermal processes such as pasteurization.

• Marine Sector: Efficiently cools engine oil and cooling water with seawater.

• HVAC Systems: Manages central heating and cooling cycles in large-scale buildings and facilities.

• Pharmaceutical Industry: Provides corrosion-resistant and leak-proof solutions in sensitive chemical production processes.

• Paper Production: Saves energy by recovering waste heat generated during production.

Tube Heat Exchanger Prices

Thanks to the ISO 9001 quality management system, which is at the core of our production discipline at Aces Process, we deliver sustainable and traceable excellence at every stage, from design to delivery. Our manufacturing capabilities, fully compliant with ASME (American Society of Mechanical Engineers) standards—recognized as the “gold standard” in the global industry—demonstrate that our equipment meets the most demanding pressure vessel criteria and can be safely used in international projects. Thanks to our expertise in ATEX (Ex-Proof) certification, which is particularly critical in flammable and explosive environments, we design our heat exchangers to be fully protected against static electricity and spark hazards, even in the most hazardous areas.

This comprehensive set of certifications and standards means that every product bearing the Aces Process signature is not just a piece of equipment, but also a globally certified commitment to safety and quality.

Bibliography:

• ASME Section VIII

• PED

• ATEX Directives

• AD2000

• EN13445

• TEMA Standards

Shell and Tube Heat Exchanger Prices: Factors and Considerations

In this article, we will delve into shell and tube heat exchangers that push the boundaries of engineering and explore their limitless potential and unique features.

As ACES engineers, we are inspired by the revolutionary impact of machines in industrial processes and are dedicated to continuously developing new processes and machines to provide lasting support to our customers. We prioritize customer satisfaction, aiming to make our clients more competitive and to be a partner in their success.

Contact

Phone : +90 536 233 30 76

Email : [email protected]

Address

Address : Ovacık Mah. Mimar Sokak No:10

Başiskele / KOCAELİ / TÜRKİYE