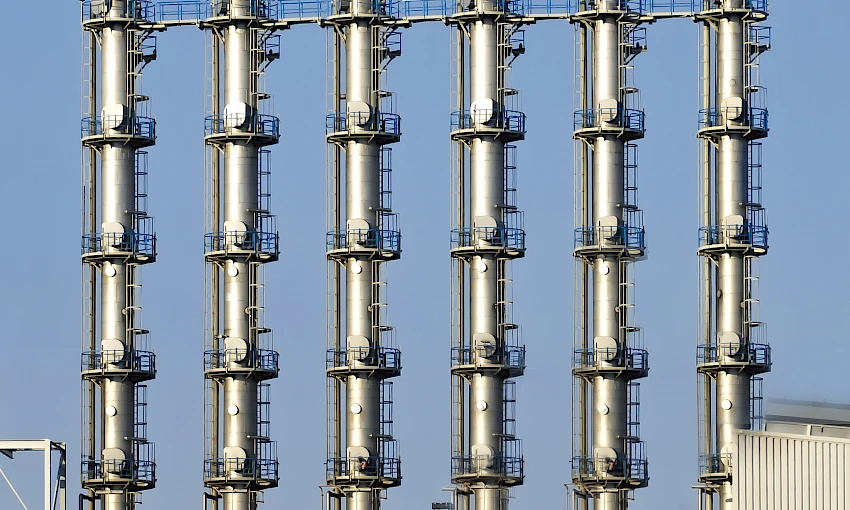

Industrial Chimney Systems: Safeguarding the Environment and Enhancing Efficiency

Industrial chimney systems are meticulously engineered structures designed to safely channel and release harmful gases and smoke generated by factories and industrial plants into the atmosphere. These systems are instrumental in mitigating environmental pollution and safeguarding human health.

Importance of Industrial Chimney Systems:

-

Reduce Environmental Pollution: Industrial chimney systems play a crucial role in curbing air pollution by ensuring the controlled and regulated release of pollutants into the atmosphere. This helps to maintain air quality and protect ecosystems.

-

Protect Human Health: By efficiently dispersing harmful gases and smoke away from ground level, chimney systems prevent these pollutants from reaching the respiratory system, safeguarding human health and well-being.

-

Increase Energy Efficiency: Well-designed chimney systems can contribute to increased energy efficiency in industrial facilities by optimizing the combustion process and reducing heat loss.

-

Ensure Compliance: Chimney systems are essential for complying with stringent environmental regulations and emission standards, helping businesses avoid penalties and legal repercussions.

Types of Industrial Chimney Systems:

Industrial chimneys are classified based on various factors, including:

-

By Material:

-

Steel chimneys

-

Aluminum chimneys

-

Stainless steel chimneys

-

-

By Draft Type:

-

Natural draft chimneys

-

Mechanical draft chimneys

-

-

By Height:

-

Short chimneys

-

Medium-height chimneys

-

Tall chimneys

-

Industrial Chimney Design:

The design of industrial chimneys involves careful consideration of several factors, including:

-

The type and capacity of the industrial facility

-

The type and quantity of emitted gases and smoke

-

The desired chimney height and diameter

-

Applicable environmental regulations and emission standards

-

Local weather conditions and terrain

Industrial Chimney Manufacturing and Installation:

Industrial chimney systems manufacturing is a specialized field that requires expertise in engineering, material science, and construction. These chimneys are designed to withstand high temperatures, corrosive environments, and structural stresses, ensuring their safe and efficient operation.

Maintenance and Repair of Industrial Chimney Systems:

Regular maintenance and repair are essential to ensure the continued safety and efficiency of industrial chimney systems. This includes inspections, cleaning, and repairs to address any wear and tear, corrosion, or structural damage.

Aces Process: Your Partner in Clean Air Solutions

At Aces Process, we specialize in the design, manufacturing, and installation of high-quality industrial chimney systems.

Our team of experts works closely with clients to develop customized solutions that meet their specific needs and comply with all relevant regulations.

We prioritize safety, efficiency, and environmental responsibility in all our projects.

Contact us today to learn more about our industrial chimney systems and how we can help you achieve cleaner air emissions.

Industrial Chimney Installation: Ensuring Safety and Environmental Responsibility

Industrial chimneys are essential structures that facilitate the controlled release of potentially harmful gases and waste from industrial facilities. Through meticulous design, production, and installation, they contribute to the protection of both human and environmental health by significantly minimizing pollution.

High-Quality Standards

Industrial chimneys must be engineered and manufactured to withstand the rigors of high temperatures, exposure to chemicals, and the potential for corrosion. Therefore, adhering to strict quality control and certification programs during the production phase is paramount. This commitment to quality guarantees that the chimneys remain durable, safe, and environmentally responsible throughout their operational lifespan.

Environmental Contributions

Industrial chimneys play a pivotal role in mitigating environmental pollution. With proper design, installation, and ongoing maintenance, chimneys can deliver the following benefits:

-

Dispersion of Pollutants: By releasing emissions at a significant height, chimneys promote the effective dispersion of harmful gases and waste, preventing them from accumulating near ground level and impacting residential areas.

-

Regulatory Compliance: Well-designed chimneys ensure adherence to emission standards and environmental regulations, contributing to a healthier and more sustainable environment.

-

Reduced Air Pollution: By effectively controlling emissions, chimneys decrease air pollution levels, leading to improved air quality and reduced health risks.

-

Greenhouse Gas Reduction: Optimizing combustion processes through efficient chimney design can lead to reduced greenhouse gas emissions, playing a part in combating climate change.

Energy Efficiency

An efficiently designed chimney system contributes to increased energy efficiency within industrial facilities. By optimizing the flow of exhaust gases, heat recovery can be improved, leading to reduced energy consumption and waste generation. This not only benefits the environment but also lowers operational costs, enhancing the facility's overall sustainability.

Custom Design Solutions

Every industrial facility possesses unique emission and chimney requirements. At Aces Process, our experienced engineers provide optimal performance and environmental compliance by designing and manufacturing chimneys tailored precisely to the specific needs of each customer.

Conclusion

Industrial chimneys are vital components in safeguarding environmental protection and energy efficiency. By selecting and installing the right chimney system, facilities can effectively control their emissions, promoting a healthier environment while optimizing their operational efficiency.

Call to Action:

Contact us for expert guidance on industrial chimney solutions

As ACES engineers, we are inspired by the revolutionary impact of machines in industrial processes and are dedicated to continuously developing new processes and machines to provide lasting support to our customers. We prioritize customer satisfaction, aiming to make our clients more competitive and to be a partner in their success.

Contact

Phone : +90 536 233 30 76

Email : [email protected]

Address

Address : Ovacık Mah. Mimar Sokak No:10

Başiskele / KOCAELİ / TÜRKİYE