Industrial Mixers & Blenders: Efficient Mixing Solutions

At Aces Process, we manufacture high-performance industrial mixers and blenders that deliver exceptional mixing capabilities across various industries. Our solutions ensure the homogeneous mixing of your raw materials, promoting consistent product quality and optimizing your production processes.

What are Industrial Mixers?

Industrial mixers are robust and versatile machines designed to process a wide array of materials, including powders,liquids, pastes, and even solids. They facilitate the thorough blending, homogenization, dispersion, or emulsification of components, ensuring a uniform and consistent final product.

Key Features of Industrial Mixers:

-

Robust Construction: Built to withstand heavy-duty industrial applications, ensuring durability and longevity.

-

High Mixing Efficiency: Powerful motors and specially designed blades or impellers deliver rapid and thorough mixing.

-

Versatile Applications: Accommodate various mixing needs, from simple blending to complex homogenization.

-

Customizable Configurations: Adaptable to specific material properties and process requirements, ensuring optimal performance.

-

Easy Maintenance: Designed for simple cleaning and maintenance, minimizing downtime and maximizing productivity.

Benefits of Aces Process Industrial Mixers:

-

Superior Mixing Quality: Ensure uniform distribution of ingredients and eliminate inconsistencies in your final product.

-

Enhanced Production Efficiency: Increase throughput and reduce processing time, improving your productivity and profitability.

-

Improved Product Consistency: Deliver consistent quality and performance, meeting customer expectations and regulatory standards.

-

Reduced Waste: Minimize material waste and improve yield through efficient mixing and blending processes.

-

Expert Support: Our experienced team provides comprehensive technical support and guidance to ensure the optimal selection and operation of your mixer.

Partner with Aces Process for Your Mixing Needs

Whether you're in the food, pharmaceutical, chemical, or any other industry requiring precise and reliable mixing solutions, Aces Process has the expertise and capabilities to meet your needs. Our range of industrial mixers and blenders is designed to handle diverse materials and processes, ensuring superior mixing performance and delivering exceptional value to your operations.

Contact us today to explore our range of industrial mixers and discover how we can help you achieve consistent and high-quality mixing results.

Need a reliable mixing solution for your production process? Explore our range of industrial mixers designed for efficiency and performance.

Types of Industrial Mixers

At Aces Process, we understand that different industries and processes demand specific mixing solutions. That's why we offer a diverse range of industrial mixers tailored to various applications, ensuring optimal performance and efficiency.

1. High Torque Mixers:

-

Designed for: Dense, viscous, and difficult-to-mix materials.

-

Key Features: Powerful motors, robust construction, and specialized mixing blades or impellers generate high torque for thorough mixing even under challenging conditions.

-

Ideal for: Industries processing heavy pastes, slurries, adhesives, sealants, rubber compounds, and other high-viscosity materials.

2. Process Mixers:

-

Designed for: A wide range of mixing, blending, and homogenization processes across various industries.

-

Key Features: Versatile configurations, customizable impellers, and adaptable designs cater to different material properties and process requirements.

-

Ideal for: Food processing, chemical production, pharmaceutical manufacturing, and other industries with varying mixing needs.

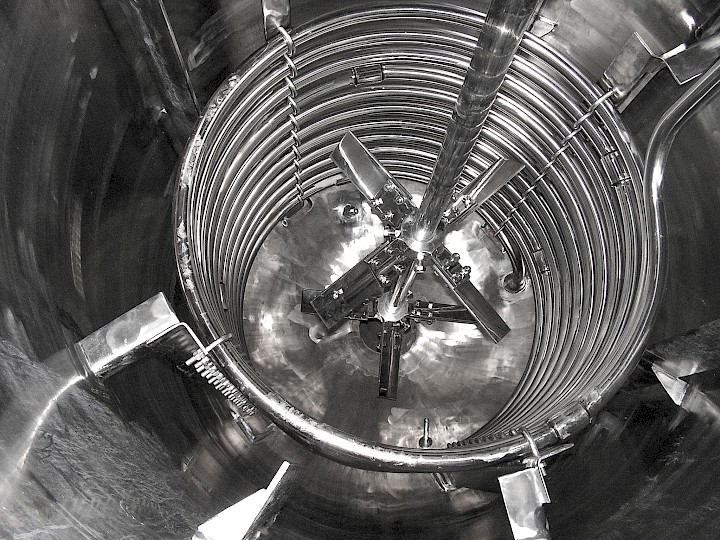

3. Stainless Steel Mixers:

-

Designed for: Hygienic and corrosive environments, particularly in the food and pharmaceutical sectors.

-

Key Features: Constructed from high-grade stainless steel, these mixers offer excellent corrosion resistance, easy cleaning, and compliance with strict hygiene standards.

-

Ideal for: Food and beverage production, pharmaceutical manufacturing, and other industries where product purity and sanitation are paramount.

4. High Capacity Mixers:

-

Designed for: Large-scale production and continuous processing.

-

Key Features: Large mixing volumes, robust construction, and efficient mixing mechanisms handle bulk quantities of materials, ensuring high throughput and productivity.

-

Ideal for: Industries requiring large-scale mixing and blending operations, such as chemical production, mining, and bulk materials handling.

5. Vertical Mixers:

-

Designed for: Space-constrained environments and applications requiring vertical material flow.

-

Key Features: Compact design, vertical mixing shafts, and specialized impellers promote efficient mixing within a smaller footprint.

-

Ideal for: Industries with limited floor space or processes involving vertical movement of materials, such as mixing dry powders or blending liquids with solids.

Aces Process: Your Mixing Solution Provider

We are committed to providing you with the right mixing solution for your specific needs. Our experienced engineers will work closely with you to understand your process requirements and recommend the ideal mixer type and configuration. Contact us today to discuss your mixing challenges and explore our comprehensive range of industrial mixers.

Industrial Mixer Applications

Industrial mixers are indispensable tools across a multitude of industries, ensuring efficient and consistent mixing of various materials. Here's a glimpse into some of the prominent sectors where they play a vital role:

-

Food Industry: Industrial mixers are used extensively for preparing a wide range of food products, including:

-

Dough: Kneading and mixing dough for bread, pastries, and other baked goods.

-

Sauces & Dressings: Blending ingredients to create smooth and flavorful sauces, dressings, and condiments.

-

Creams & Emulsions: Creating stable emulsions like mayonnaise, ice cream, and cosmetic creams.

-

Beverages: Mixing and homogenizing ingredients for juices, soft drinks, and alcoholic beverages.

-

-

Chemical Industry: Industrial mixers facilitate various chemical processes, including:

-

Paints & Coatings: Dispersing pigments and additives into resins to create paints, coatings, and inks.

-

Resins & Polymers: Blending and homogenizing monomers and additives in the production of various plastics and resins.

-

Chemicals: Mixing chemicals for fertilizers, pesticides, cleaning agents, and other industrial applications.

-

-

Pharmaceutical Industry: Industrial mixers play a critical role in drug manufacturing, ensuring precise and uniform mixing of:

-

Drug Mixtures: Blending active pharmaceutical ingredients (APIs) with excipients to create tablets,capsules, and other dosage forms.

-

Creams & Ointments: Homogenizing pharmaceutical creams and ointments to achieve consistent texture and drug distribution.

-

-

Cosmetics Industry: Industrial mixers contribute to the creation of a wide range of cosmetic products, including:

-

Makeup: Blending pigments, oils, and other ingredients to create foundations, lipsticks, and other makeup products.

-

Skincare: Creating lotions, creams, and serums with a smooth and even texture.

-

Haircare: Mixing shampoos, conditioners, and hair styling products to achieve desired consistency and performance.

-

Choosing the Right Industrial Mixer

Selecting the appropriate industrial mixer involves careful consideration of several key factors:

-

Material to be Mixed: The properties of the materials, such as viscosity, density, and particle size, significantly influence the choice of mixer type and design.

-

Desired Mixing Homogeneity: The required level of mixing uniformity dictates the type of impeller, mixing speed, and processing time.

-

Production Capacity: The volume of material to be processed influences the size and capacity of the mixer.

-

Budget: Consider the initial investment, operating costs, and potential return on investment (ROI) when choosing a mixer.

-

Additional Requirements: Specific requirements like temperature control, sanitation, and explosion-proof design may also influence the selection.

At Aces Process, our team of experts can assist you in selecting the optimal industrial mixer based on your unique needs and process parameters.

We offer a wide range of mixers and blenders, each designed to deliver exceptional performance and ensure the consistent quality of your products.

Contact us today to discuss your mixing requirements and find the perfect solution.

Common Types of Industrial Mixers

Industrial mixers come in various shapes and sizes, each tailored to specific mixing needs and material properties. Here are some of the most common types you'll encounter:

- Conical Mixer:

-

Description: Features a cone-shaped vessel with a rotating screw or ribbon agitator.

-

Advantages: Gentle mixing action, ideal for fragile materials, easy to clean, efficient discharge.

-

Suitable for: Dry powders, granules, and fragile products.

- Double Arm Mixer:

-

Description: Employs two counter-rotating mixing blades with a sigma or Z-shaped profile.

-

Advantages: High mixing efficiency, handles high-viscosity materials, excellent for dough and pastes.

-

Suitable for: Food processing, chemicals, pharmaceuticals, and other industries requiring thorough mixing of viscous materials.

- Paddle Mixer:

-

Description: Utilizes paddles or blades mounted on a central shaft to agitate and mix materials.

-

Advantages: Simple and cost-effective, suitable for low to medium viscosity liquids and powders.

-

Suitable for: Blending liquids, mixing powders, and creating suspensions.

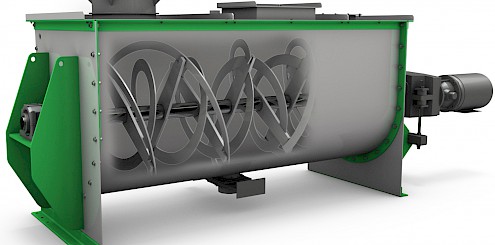

- Ribbon Mixer:

-

Description: Features a horizontal U-shaped trough with helical ribbons that rotate on a central shaft.

-

Advantages: Versatile for various materials and viscosities, gentle mixing action, efficient heat transfer.

-

Suitable for: Blending dry powders, granules, and pastes.

- Vacuum Mixer:

-

Description: Mixes materials under vacuum conditions, removing air bubbles and preventing oxidation.

-

Advantages: Ideal for creating smooth and homogeneous mixtures, prevents contamination and degradation of sensitive materials.

-

Suitable for: Pharmaceuticals, cosmetics, adhesives, and other industries requiring air-free mixing.

- Homogenizer:

-

Description: Forces materials through a small orifice at high pressure, creating a uniform and stable emulsion.

-

Advantages: Creates extremely fine particle sizes, ideal for emulsions, dispersions, and suspensions.

-

Suitable for: Food processing, pharmaceuticals, cosmetics, and other industries requiring homogenization of immiscible liquids.

Remember:

The optimal mixer type depends on your specific application, materials, desired mixing outcome, and budget.

At Aces Process, our experienced team can help you evaluate your requirements and select the ideal mixer for your process, ensuring efficient and consistent mixing results.

Contact us today to discuss your mixing needs and find the perfect solution.

Benefits of Aces Process Industrial Mixers

At Aces Process, our industrial mixers are designed to elevate your mixing processes, providing superior performance, reliability, and efficiency. Here's what sets our mixers apart:

-

High-Performance Motors: Equipped with robust and powerful motors, our mixers deliver consistent and reliable performance even when handling heavy-duty or high-viscosity materials. This translates to shorter mixing times and increased productivity.

-

Durable Construction: Our mixers are built using high-quality materials and advanced fabrication techniques, ensuring long-lasting durability even in demanding industrial environments. This minimizes maintenance requirements and reduces downtime, saving you valuable resources.

-

User-Friendly Design: We prioritize ease of operation and maintenance in our mixer designs. Intuitive controls, ergonomic features, and accessible components make our mixers user-friendly and simple to operate, clean, and maintain.

-

Faster, More Efficient, and Higher Quality Mixing: Our mixers are engineered to deliver optimal mixing performance, ensuring fast and thorough blending, homogenization, or dispersion of your materials. This results in improved product quality, consistency, and yield, contributing to your overall process efficiency.

Additional Advantages:

-

Customization: We understand that each application is unique. That's why we offer customization options, tailoring our mixers to your specific requirements, ensuring a perfect fit for your process.

-

Expert Support: Our team of experienced engineers provides comprehensive technical support and guidance, from selecting the right mixer to installation and maintenance, ensuring seamless integration into your operations.

-

Competitive Pricing: We offer competitive pricing without compromising quality, delivering exceptional value and a strong return on investment.

Contact Aces Process

Experience the Aces Process Difference:

Discover how Aces Process industrial mixers can revolutionize your mixing processes, delivering superior performance, efficiency, and reliability.

Upgrade your production with our custom-designed industrial mixers! Contact us today for a quote and expert consultation.

Heavy Duty Mixers and High-Performance Industrial Mixers

When it comes to Heavy Duty Mixers, trust the experts at Aces Process. We offer a wide range of Heavy Duty Mixers for all types of industries, from food and beverage to chemical and pharmaceutical. You'll discover the perfect mix with our Heavy Duty Mixers.

Ribbon Mixers

Ribbon mixers are an excellent solution that ensures homogeneous mixing and fast processing of materials used in various sectors.

As ACES engineers, we are inspired by the revolutionary impact of machines in industrial processes and are dedicated to continuously developing new processes and machines to provide lasting support to our customers. We prioritize customer satisfaction, aiming to make our clients more competitive and to be a partner in their success.

Contact

Phone : +90 536 233 30 76

Email : [email protected]

Address

Address : Ovacık Mah. Mimar Sokak No:10

Başiskele / KOCAELİ / TÜRKİYE