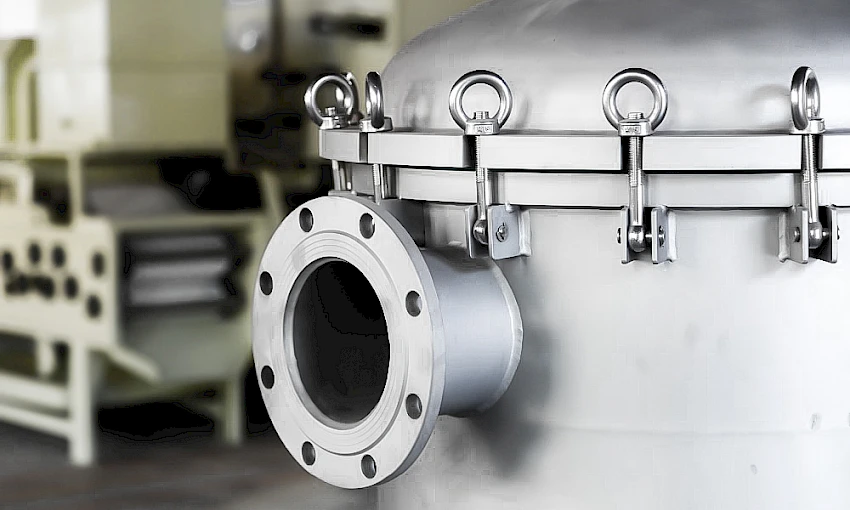

Stainless Steel Filter Housings: Precision Filtration Solutions

Aces Process is a recognized leader in the design, manufacturing, and supply of top-tier stainless steel filter housings. We cater to diverse filtration needs across various industries, crafting housings engineered for exceptional performance, durability, and adaptability.

What is a Filter Housing?

A filter housing acts as the protective shell within a filtration system. It securely houses the filter element (e.g., cartridges, bags, or baskets), directing the flow of fluids or gases through it. This controlled passage facilitates the efficient removal of impurities and contaminants, ensuring the purity and safety of the filtered substance.

What is a Stainless Steel Filter?

Stainless steel filters are critical components utilized across many industrial sectors. Crafted from high-grade stainless steel alloys, they boast remarkable corrosion resistance, robustness, and strength. Their meticulous design enables them to effectively eliminate particles and contaminants from both liquids and gases, guaranteeing product purity and safety.

Partner with Aces Process:

At Aces Process, we leverage our extensive experience and cutting-edge technology to manufacture stainless steel filter housings that meet and exceed expectations. Our commitment to quality, performance, and customer satisfaction sets us apart. Contact us today to discover how our filtration solutions can enhance the efficiency and reliability of your processes.

Applications of Stainless Steel Filters

Stainless steel filters find diverse uses across numerous industries due to their robust construction and resistance to corrosion. They play a crucial role in ensuring product purity, safety, and process efficiency in various applications.

-

Food & Beverage: Maintaining product quality and safety by filtering out impurities, contaminants, and microorganisms from beverages, dairy products, sauces, and more.

-

Chemical Processing: Effectively filtering chemicals, acids, and bases, protecting equipment, ensuring product purity, and preventing environmental contamination.

-

Oil & Gas: Removing contaminants from crude oil, refined products, and petrochemicals, enhancing process efficiency and product quality.

-

Pharmaceutical: Maintaining strict hygiene standards and preventing contamination in drug production by filtering out unwanted particles and bacteria.

-

Water Treatment: Purifying and disinfecting water for various uses, including drinking, industrial processes, and wastewater treatment.

-

Automotive: Filtering engine oil, transmission fluids, and other fluids to prevent wear and tear on critical engine components.

-

Aviation: Filtering aircraft fuel and hydraulic fluids, ensuring the safe and reliable operation of aircraft systems.

Advantages of Stainless Steel Filters

Stainless steel filters offer numerous benefits that make them an ideal choice for demanding filtration applications:

-

Long Lifespan: Resistant to corrosion, abrasion, and wear, stainless steel filters provide long-lasting performance and minimize the need for frequent replacements.

-

Low Maintenance: Their smooth surface and inherent resistance to fouling make them easy to clean and require minimal upkeep, reducing downtime and maintenance costs.

-

Chemical Resistance: Stainless steel withstands a wide range of chemicals and aggressive environments, making them suitable for various industrial processes.

-

High Temperature & Pressure Tolerance: They can handle high temperatures and pressures, ensuring reliable performance in demanding applications.

-

Eco-Friendly: Stainless steel is a recyclable material, contributing to environmental sustainability and minimizing waste.

Why Choose Aces Process for Your Stainless Steel Filters?

-

Extensive Experience: We possess years of expertise in designing and manufacturing stainless steel filters, ensuring superior quality and performance.

-

Uncompromising Quality: We use only the finest materials and adhere to stringent quality control measures throughout the production process, guaranteeing the reliability and longevity of our filters.

-

Wide Selection: We offer a comprehensive range of standard and custom filters, tailored to meet your specific filtration needs and application requirements.

-

Competitive Pricing: Our stainless steel filters offer exceptional value, providing high-quality solutions at affordable prices.

-

Fast & Reliable Delivery: We understand the importance of timely delivery. We strive to provide fast and reliable shipping to ensure your filters reach you quickly and safely.

Partner with Aces Process:

For top-quality stainless steel filters and exceptional customer service, choose Aces Process.

Our dedication to innovation, quality, and customer satisfaction makes us your ideal filtration partner.

Contact us today to discuss your filtration needs and discover how our solutions can enhance your process efficiency and product quality.

Types of Stainless Steel Filters

Stainless steel filters come in a variety of configurations to accommodate the diverse needs of different industries and processes. Here are some of the common types offered by Aces Process:

-

Cylindrical Filters:

-

The most versatile and widely used type, accommodating a variety of filter media like mesh, sintered metal, or pleated elements.

-

Offer high flow rates and efficient filtration, suitable for various applications across multiple industries.

-

-

Cartridge Filters:

-

House replaceable cartridge elements, making maintenance and cleaning convenient and efficient.

-

Ideal for applications requiring frequent filter changes or where sterility is critical.

-

-

High-Pressure Filters:

-

Designed with reinforced housings and specialized seals to withstand high pressures and extreme operating conditions.

-

Essential for industries like oil & gas, chemical processing, and power generation.

-

-

Bag Filters:

-

Utilize filter bags to capture larger particles and contaminants, providing effective pre-filtration or final filtration in certain applications.

-

Commonly used in water treatment, wastewater treatment, and industrial processes involving bulk solids removal.

-

Stainless Steel Filter Selection

Choosing the right stainless steel filter for your application is crucial for ensuring optimal filtration performance and cost-effectiveness. Key factors to consider include:

-

Application: The specific industry, process, and fluid characteristics will determine the appropriate filter type and material selection.

-

Desired Filtration Level: The required level of particle removal and filtration efficiency influences the choice of filter media and pore size.

-

Flow Rate & Pressure: The flow rate and operating pressure of the system dictate the filter housing size and pressure rating.

-

Contaminant Type: The type of contaminants present in the fluid will guide the selection of filter media and filtration mechanism.

-

Budget: Consider the initial investment, operating costs, and maintenance requirements when choosing a filter.

Aces Process: Your Filtration Partner

At Aces Process, our experienced team is ready to assist you in selecting the optimal stainless steel filter for your application.

We offer a comprehensive range of filters and expert guidance, ensuring efficient and reliable filtration performance tailored to your specific needs.

Contact us today to discuss your filtration requirements and discover the perfect solution.

Contact Us

Basket Filters

Our basket filters offer the highest efficiency and performance to meet businesses' needs for filtering sediment, particles, and solid materials.

As ACES engineers, we are inspired by the revolutionary impact of machines in industrial processes and are dedicated to continuously developing new processes and machines to provide lasting support to our customers. We prioritize customer satisfaction, aiming to make our clients more competitive and to be a partner in their success.

Contact

Phone : +90 536 233 30 76

Email : [email protected]

Address

Address : Ovacık Mah. Mimar Sokak No:10

Başiskele / KOCAELİ / TÜRKİYE