Storage Tank Design, Manufacturing, and Installation Services

In today's industrial facilities, a properly designed storage tank is of strategic importance for the safe and long-term storage of chemicals, water, fuel, solvents, food raw materials, or process fluids.

As ACESPROCESS, we carry out end-to-end design, engineering, manufacturing, assembly, and commissioning processes in accordance with international standards, primarily API 650 / API 620 / EN 14015 / EN13445.

What is a Storage Tank? Why is Proper Design Important?

Storage tanks are specially designed for the safe, controlled, and long-term storage of liquids, gases, chemicals, or other fluid materials, with capacities ranging from 100 liters to 250 cubic meters.

The quality of a storage tank is measured by criteria such as:

-

Corrosion resistance

-

Leak-tightness

-

Chemical compatibility

-

Mechanical strength

-

Operational safety

Choosing the wrong tank creates both a safety risk and high maintenance costs for the operation.

Therefore, tank design must be based on the technical characteristics of the product to be stored:

temperature, pressure, viscosity, density, pH, corrosive structure, etc.

Storage Tank Solutions

1. Engineering and Custom Design

At the beginning of the project, detailed engineering calculations are performed according to product specifications and facility requirements:

-

Static & mechanical analyses

-

Body sheet thickness calculations

-

Nozzle orientation

-

Carrier system design

-

Jacket / coil / heating-cooling options

-

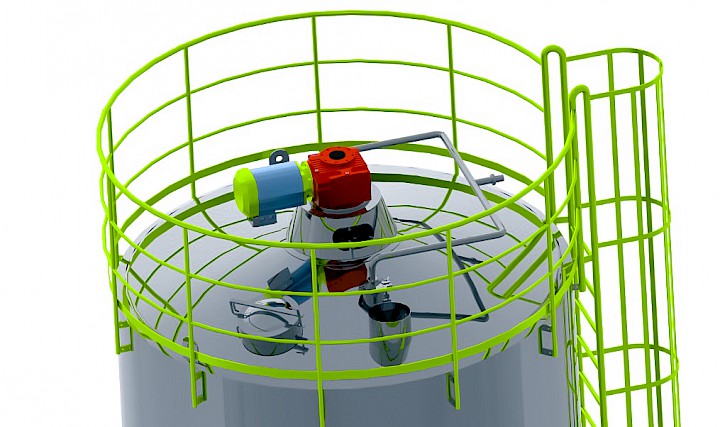

Mixer integration

-

Insulation and coating options

Completely customized 3D models are prepared for each project.

2. Manufacturing Stainless Steel and Carbon Steel Tank Production

All our production is carried out using:

• AISI 304 / 304L / 316 / 316L / 316TI stainless steel,

• ST37 / P265GH / S235JR / S355JR carbon steel,

• Special alloy steel and Duplex

materials, under full quality control.

Manufacturing steps:

• Sheet cutting and forming

• Automatic and manual TIG/MIG/SAW welding

• Heat treatment and surface cleaning

• Non-destructive testing (PT, UT, RT)

• Pressure, hydrostatic testing, and leak testing

3. Field Installation and Commissioning

Tanks are installed on site by our expert installation team.

• Anchoring, ground preparation, support structure

• Nozzle and line connections

• Sensor, level indicator, valve, and instrumentation installation

• Pre-commissioning test and checklist

After installation, the tank is delivered fully tested.

Storage Tank Applications

Our storage tanks are widely used in the following sectors:

• Chemical and petrochemical plants

• Water treatment and process water storage

• Food and pharmaceutical industry

• Fuel & solvent storage

• Energy plants

• Textile, paint, and mining industries

• Industrial process lines

Why ACESPROCESS

Engineering and quality assurance in compliance with international standards

• Custom design & manufacturing tailored to customer requirements

• Stainless steel expertise

• Turnkey project management

• Complete solutions including field installation, testing, and commissioning

• High-strength, long-lasting, maintenance-friendly tanks

Storage Tank Types

-

Stainless Steel Storage Tank

-

Carbon Steel Storage Tank

-

Chemical Storage Tank

-

Vertical/Horizontal Cylindrical Tank

-

Atmospheric Tanks

-

Pressurized Storage Tanks

-

Heated/Cooled Tanks

-

Agitated Process Tanks

-

Silos and Raw Material Storage Tanks

As Aces Process, we meticulously analyze all details, from the chemical properties of the liquid you will store to the space constraints at your facility, offering customized storage solutions tailored to your needs.

We demonstrate a strong presence in the global market with our exports to over 52 countries. We deliver the Aces Process guarantee to our business partners around the world, primarily in Europe, the Middle East, and the Americas.

Contact us today for customized storage tank solutions.

Stainless Steel Tank

Stainless steel tanks are typically made from 304, 316, or 321 stainless steel. The choice of material depends on the properties of the liquid to be stored, its corrosion resistance, and other factors.

Expansion Tanks

Trust Aces Expansion Tanks to keep your liquids under control and make your system work more efficiently! Aces is an industry-leading manufacturer of expansion tanks and offers customized solutions for our customers.

As ACES engineers, we are inspired by the revolutionary impact of machines in industrial processes and are dedicated to continuously developing new processes and machines to provide lasting support to our customers. We prioritize customer satisfaction, aiming to make our clients more competitive and to be a partner in their success.

Contact

Phone : +90 536 233 30 76

Email : [email protected]

Address

Address : Ovacık Mah. Mimar Sokak No:10

Başiskele / KOCAELİ / TÜRKİYE