Production Machinery: Chemical, Food, Pharmaceutical & Cosmetics

The chemical, food, pharmaceutical, and cosmetic industries are vital sectors that meet the basic needs of human life and contribute significantly to the global economy. Seamless and efficient operation of production processes in these sectors is crucial for delivering reliable and high-quality products.

Production machinery forms the backbone of these complex and sensitive manufacturing processes. Selecting and utilizing the right machines plays a critical role in increasing production capacity, reducing costs, and maximizing product quality.

At Aces Process, we offer a wide range of production machinery designed to meet the specific needs of these sectors. Our expert team develops the most suitable solutions by analyzing the unique requirements of our customers and utilizing the latest technology.

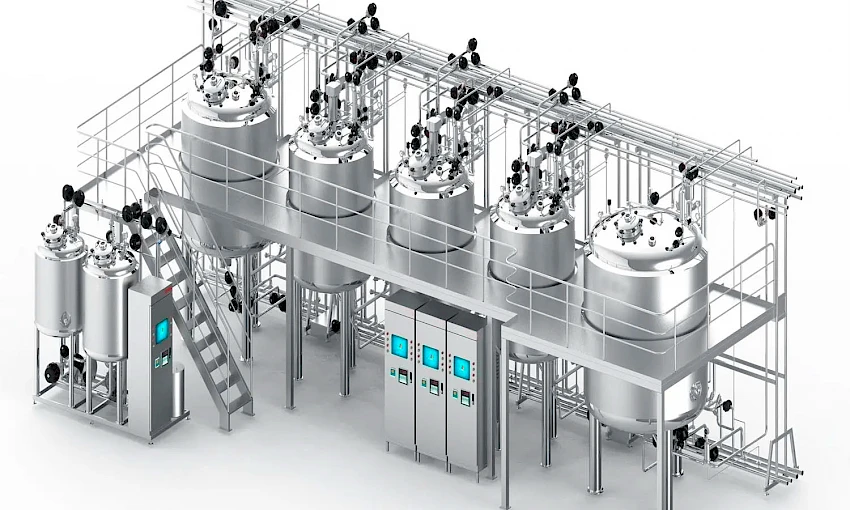

Chemical Production Machinery

Production lines, the heart of the chemical industry, cannot deliver the desired results without robust and efficient production machinery. As Aces Process, a company specializing in chemical production machinery, we offer all the solutions you need to establish your dream production line.

Advantages Offered by Aces Process:

-

20 Years of Experience: With over 20 years of experience, we understand the needs and challenges of the chemical industry.

-

Expert Team: We work with a team of experienced engineers and technicians.

-

Wide Product Range: Our product range includes mixing tanks, reactors, filters, dryers, and many other chemical production machines.

-

Customized Solutions: We offer customized solutions tailored to the specific needs of our customers.

-

Quality and Reliability: We offer reliable and durable machines manufactured to the highest quality standards.

-

Competitive Prices: We offer the highest quality at the most affordable prices.

With Aces Process:

-

Increase your production capacity

-

Reduce your costs

-

Maximize your product quality

-

Establish a safer and more efficient production line

Contact us now and discover the most suitable chemical production machines for you!

Food Production Machinery

Production lines, the heart of the food industry, cannot deliver the desired taste and efficiency without reliable and high-performance food production machines. As Aces Process, a company specializing in food production machinery, we offer all the solutions you need to establish your dream production line.

Advantages Offered by Aces Process:

-

20 Years of Experience: With over 20 years of experience, we understand the needs and challenges of the food industry.

-

Expert Team: We work with a team of experienced engineers and technicians.

-

Wide Product Range: Our product range includes dough processing machines, baking equipment, cooling systems, packaging machines, and many other food production machines.

-

Customized Solutions: We offer customized solutions tailored to the specific needs of our customers.

-

Hygiene and Safety: We offer machines manufactured in accordance with the highest hygiene and safety standards.

-

Durability and Performance: We offer long-lasting and high-performance machines.

-

Competitive Prices: We offer the highest quality at the most affordable prices.

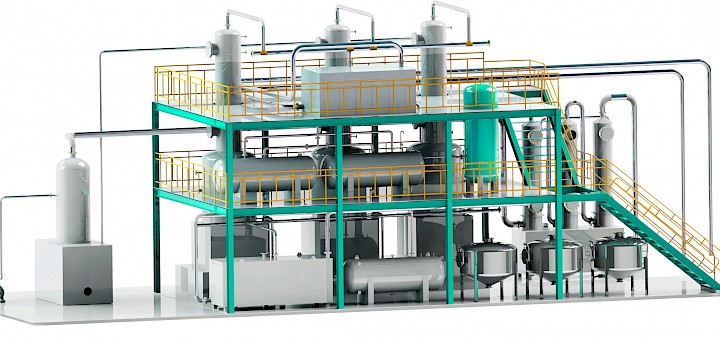

Pharmaceutical Production Machinery

Production lines, one of the most important elements of the pharmaceutical industry, cannot provide the desired quality and trust without reliable and precise pharmaceutical production machines. As Aces Process, a company specializing in pharmaceutical production machinery, we offer all the solutions you need to establish your dream production line.

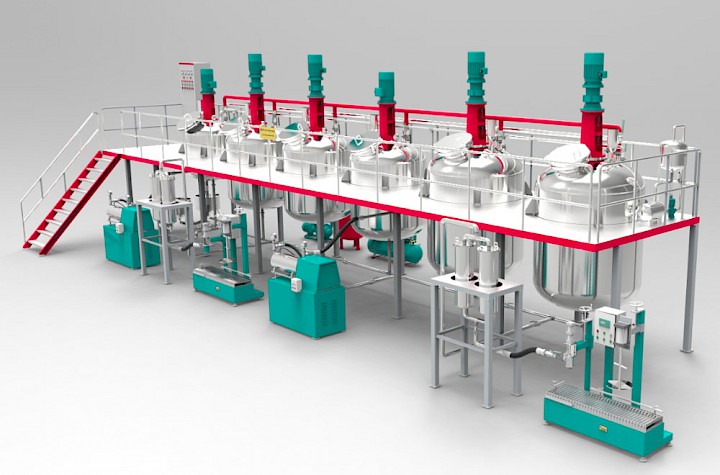

Cosmetic Production Machinery

Production lines, the heart of the cosmetic industry, cannot deliver the desired beauty and efficiency without reliable and high-performance cosmetic production machines. As Aces Process, a company specializing in cosmetic production machinery, we offer all the solutions you need to establish your dream production line.

Production Machinery Design Process

The design of production machinery is a complex process and requires detailed analysis and planning to meet industry-specific requirements. Aces Process works in close collaboration with its expert engineering staff to understand the needs of its customers. We offer customized solutions considering customers' production goals, capacity requirements, quality standards, and safety measures.

During the design phase, Aces Process engineers create machine prototypes using 3D modeling and simulation tools.These prototypes are used to obtain customer feedback and make design improvements. This process minimizes the costs and risks of the production process and ensures that the final product delivers the expected performance.

Production Machinery Manufacturing Process

Once the design is approved, Aces Process proceeds to the manufacturing process in its modern facilities. The company's experienced manufacturing team carries out the manufacturing of the machines using high-quality materials and state-of-the-art equipment. Strict quality controls are applied during this process, and production engineers work meticulously to ensure the accuracy of the process at every stage.

Frequently Asked Questions and Expert Comments about Production Machinery:

What are production machines and how are they used in industrial sectors?

Production machines are special equipment used in the production processes of various industries. These machines are designed to perform processes such as material handling, assembly, packaging, filling, new product development, and measurement. Production machines are integrated with automation technologies to provide facilities with various advantages such as efficiency, quality, cost, and time. In industrial sectors, production machines are used in many areas such as chemical, food, pharmaceutical, automotive, electronics, and metal processing.

What is the importance of industrial machines and their applications in different sectors?

The importance of industrial machines is increasing day by day in modern production processes. Today, businesses make significant investments in industrial machines to increase their efficiency, improve production quality, reduce costs, and gain a competitive advantage. Here are some of the applications of industrial machines in different sectors:

- Food and Beverage Industry: Food processing, packaging and filling machines, industrial ovens, cooling systems,and mixing machines are widely used in the food and beverage industry.

- Chemical and Pharmaceutical Industry: In the chemical and pharmaceutical industry, industrial machines such as reactors, mixing machines, drying systems, tablet production machines, and packaging machines are used. These machines play an important role in the production of chemicals, drug formulation, mixing, and packaging processes.

What are the basic principles and processes of machine manufacturing?

Design Process of Production Machines

What are the design stages and engineering requirements of production machines?

-

Needs Analysis: The first step in the design process is to analyze the needs of the customer or user. At this stage,factors such as the user's production goals, capacity requirements, product features, safety requirements, quality standards, and budget are taken into consideration. Close communication and collaboration with the customer ensure that the needs are fully understood.

-

Concept Design: Based on the requirements identified as a result of the needs analysis, a concept design is created.At this stage, the functions, components, operating principles, and general structure of the machine are determined.Our design teams visualize the concept design and perform performance analyses using 3D modeling and simulation tools.

-

Detailed Design: Once the concept design is approved, the detailed design phase is started. At this stage, details such as the dimensioning of machine parts, material selection, design of motion mechanisms, and determination of fasteners are addressed. In addition, suitability for production, assembly, and maintenance processes is considered.

-

Mechanical and Electrical/Hydraulic/Pneumatic System Design: The design and integration of mechanical,electrical, hydraulic, and pneumatic systems in production machines are important. The correct operation of these systems is critical to the efficiency, safety, and performance of the machine. Our design experts select system components, plan connections, and design control mechanisms.

-

Material Selection and Durability Analysis: Material selection is of great importance for production machines to be robust, durable, and long-lasting. Our designers select materials suitable for the operating conditions and perform durability analyses to ensure that the machines maintain their performance for a certain period of time.

-

Safety and Occupational Health Design: It is important to comply with occupational safety and health standards during the design of production machines. Our design engineers assess potential risks, plan protective measures,and add the necessary safety equipment to prevent accidents that may occur during the use of the machine.

-

Prototype Production and Testing: After the design stages are completed, a prototype production machine is manufactured. This prototype is subjected to rigorous durability tests to evaluate how the design works and performs in the real world. Necessary improvements are made according to the test results, and the design is finalized.

-

Manufacturing Process: Once the design is approved, the production of the machine is started. In the manufacturing process, steps such as material procurement, part production, assembly, and testing are followed. Quality control measures are applied at every stage of the process, and it is verified that the machine is manufactured according to specifications.

Throughout the design stages, our engineers demonstrate engineering skills such as technical knowledge, analytical skills,design software, and mastery of relevant standards. They also demonstrate teamwork, communication skills, and good organization for the timely completion of projects.

What are the 3D modeling and simulation techniques used in machine design?

The 3D modeling and simulation techniques used in machine design can be listed as follows:

-

CAD (Computer-Aided Design): CAD software allows the design of objects in 2D or 3D. Designers can use CAD software to create the geometry of parts, dimension them, and perform their assembly.

-

CAM (Computer-Aided Manufacturing): CAM software is used to convert design data into a manufacturing process. This software determines the machining methods of the designed parts, creates cutting paths, and provides CNC (Computer Numerical Control) machines with processing instructions.

-

FEA (Finite Element Analysis): FEA is a technique used to simulate the physical properties of a structure or part,such as stress, deformation, and heat transfer. Designers analyze their designs in a virtual environment through FEA software and evaluate the performance, durability, and safety of the parts. FEA plays an important role in the optimal sizing of parts, material selection, and design improvements.

-

Kinematic Simulation: Kinematic simulation is used to analyze the motion of mechanical systems. Designers can observe how parts or assemblies move, their kinematic connections, and interactions through kinematic simulation software. These simulations help optimize mechanisms for accurate and smooth machine operation.

-

Fluid Dynamics Simulation: Fluid dynamics simulation is used to analyze the flow and interaction of liquids or gases.These simulations allow designers to evaluate factors such as pipe systems, pump and fan performance, heat transfer, and fluid pressure losses. This enables energy efficiency, proper fluid distribution, and optimal design.

These 3D modeling and simulation techniques allow for more accurate and efficient analysis in machine design. Designers can optimize the design in a virtual environment, reducing costs, saving time, and detecting design errors in advance.

The Manufacturing Process of Production Machines

Materials and Manufacturing Techniques Used in the Production of Production Machines

Various materials and manufacturing techniques are employed in the production of production machines. The materials and techniques used in the manufacturing process can vary depending on the design, purpose, and application areas of the machines. Here are some commonly used materials and manufacturing techniques:

Materials:

-

Steel: Often a preferred material in production machines due to its durability, high strength, and machinability. Different types of steel can be selected according to various applications.

-

Aluminum: Preferred for its lightweight, corrosion resistance, and machinability. It can be especially useful in portable or mobile machines.

-

Cast Iron: Used in the manufacturing of some machines due to its high-temperature resistance and vibration absorption properties. Different types of cast iron have different strengths and properties.

-

Plastic: Plastic materials may be preferred in the manufacturing of some parts. Plastics can be lightweight, durable, chemically resistant, and economical. Plastic parts can be produced especially by using plastic injection molding technology.

Manufacturing Techniques:

-

Machining: Processes that involve removing material to achieve the desired shape, such as milling, turning, and drilling.

-

Casting: Molten material is poured into a mold to create the desired shape.

-

Welding: Joining materials together using high heat to melt the parts and create a fusion.

-

Extrusion: Material is pushed through a die to create a continuous shape.

-

Printing and Molding: Techniques like 3D printing and injection molding are used to create complex shapes.

This is just a general overview, and the materials and manufacturing techniques for production machines vary according to specific applications and requirements.

At What Stages of the Manufacturing Process are Quality Control and Assurance Measures Applied?

Quality control and assurance measures are applied at different stages of the production process of production machines.Here is an overview of the stages where these measures are generally taken:

-

Incoming Inspection: In the first stage of the manufacturing process, the quality of the materials and components to be used is checked. The properties, compliance with standards, and accuracy of the materials are evaluated.

-

Process Control: In the subsequent stages of the manufacturing process, quality control of the operations to be performed is carried out. These operations include steps such as processing, shaping, assembly, or testing of parts.

-

In-Process Inspections: In-process inspections are carried out at certain points in the manufacturing process. These inspections are performed to assess the quality of the product at intermediate stages and to detect errors early.

-

Final Inspection: In the final stage of the manufacturing process, the production machines are completed, and a final inspection is carried out. These inspections are performed to assess the final quality, performance, and functionality of the product. Specific tests and experiments are conducted at this stage.

-

Quality Assurance: Quality assurance measures are applied at every stage of the manufacturing process. Quality assurance includes measures such as following standards, applying processes according to defined procedures, using quality management systems, and monitoring certification processes.

These steps demonstrate our company's overall quality control and assurance measures.

What are the Basic Features of Production Machines?

The basic features of production machines are:

-

Efficiency: Production machines increase production efficiency by speeding up processes.

-

Reliability: The reliability of the machines ensures a continuous and trouble-free production process.

-

Durability: It is important that the machines are long-lasting and can withstand intensive working conditions.

-

Flexibility: Production machines should be able to adapt to different production needs and easily adapt to changes.

-

Automation: Automatic control systems and process automation increase the efficiency of production machines and minimize human error.

-

Precision: Production machines operate with high precision, ensuring that products meet the desired quality standards.

-

Safety: It is of great importance that the machines comply with safety standards and include worker safety measures.

-

Ease of Maintenance and Service: The maintenance and repair of the machines should be easy, and service should be provided quickly when necessary.

-

Energy Efficiency: Optimizing the energy consumption of production machines reduces operating costs and supports environmental sustainability.

-

Compliance: It is important that the machines comply with industrial standards, meet sectoral requirements, and comply with legal regulations.

What are the Costs of Production Machines?

The cost of production machines can vary depending on many factors and is usually determined based on the characteristics, complexity, size of the machine, and the sector in which it will be used.

What is the Impact of Industrial Automation on Production Processes?

Industrial automation makes production processes more efficient, productive, and competitive. It offers businesses better quality, faster production, and lower costs. Therefore, many industries are adopting automation technologies to gain a competitive advantage.

How are the Maintenance and Repair Processes of Production Machines Carried Out?

Maintenance and repair processes increase the reliability and performance of production machines. Regular maintenance and repair operations extend the life of the machine, reduce the risk of failure, and increase operational efficiency.

Here are the steps generally followed for carrying out the maintenance and repair processes of production machines:

-

Preventive Maintenance Planning

-

Routine Maintenance

-

Periodic Maintenance

-

Fault Repair

-

Recording and Monitoring

-

Training and Personnel Competency

-

Spare Parts Management

Why is Ergonomics Important in Machine Design?

Ergonomics in machine design is of great importance so that users can perform their work more efficiently and safely. The ergonomic design of work requires considering various factors to protect the physical and psychological health of employees, prevent occupational accidents and injuries, reduce fatigue, and increase work efficiency.

How to Increase Efficiency with the Use of Production Machines?

The effective and efficient use of production machines increases the productivity of businesses. Here are some important factors to increase efficiency with the use of production machines:

-

Operation of the Machine at Optimum Performance

-

Operator Skills and Training

-

Efficient Production Planning

-

Automation and Control Systems

-

Data Analysis and Improvement

Which sectors does Aces Process serve?

Aces Process provides Design, Manufacturing, and Installation services for the Chemical, Food, Petrochemical, Pharmaceutical, Recycling, and Marine sectors.

Whether you're in the chemical, food, pharmaceutical, or cosmetic industry, Aces Process has the production machinery you need to succeed.