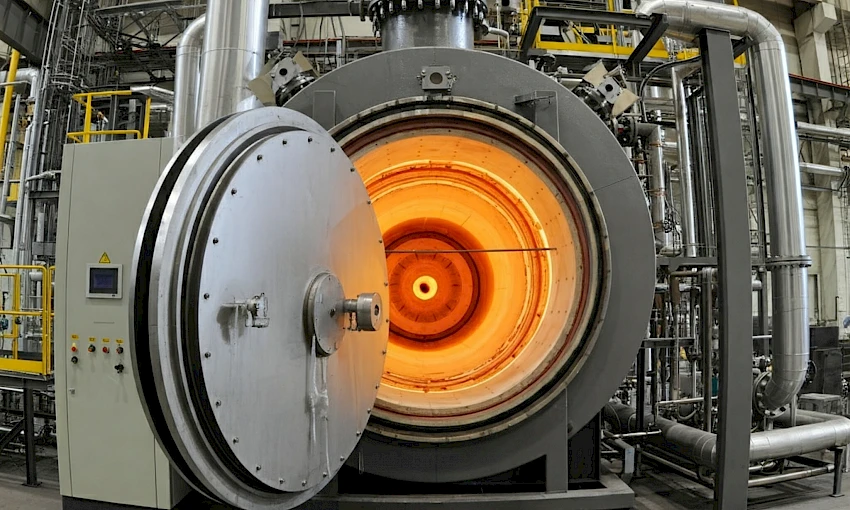

Vacuum Furnaces: Advanced Heat Treatment for Superior Material Properties

A vacuum furnace is a specialized industrial furnace that operates in a vacuum environment, meaning the air within the furnace chamber is removed to create a low-pressure environment. This unique environment offers significant advantages for various heat treatment processes.

What is a Vacuum Heat Treatment Furnace?

Vacuum heat treatment furnaces are specifically designed to perform a range of heat treatment processes on materials like metals, ceramics, and composites in a vacuum. These processes include:

-

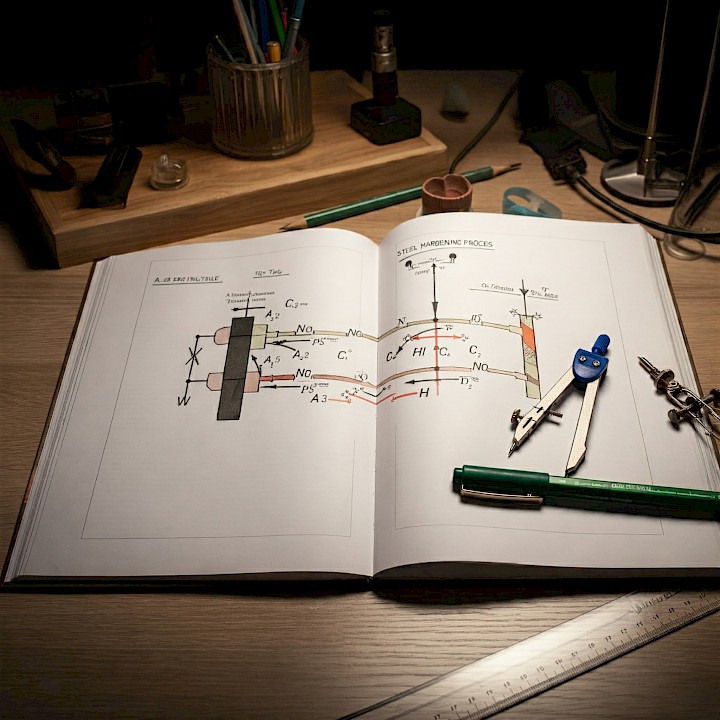

Hardening: Increasing the hardness of a material by heating and rapid cooling.

-

Tempering: Reducing the brittleness of a hardened material while maintaining its strength.

-

Annealing: Softening a material to improve ductility and reduce internal stresses.

-

Brazing: Joining two or more materials using a filler metal that melts at a lower temperature.

-

Sintering: Forming a solid mass of material by heating without melting.

Key Components of a Vacuum Heat Treatment Furnace:

-

Heating Chamber: A well-insulated chamber where the workpiece is heated.

-

Vacuum System: Pumps and gauges create and maintain the vacuum environment.

-

Heating Elements: Typically made of graphite or molybdenum, these elements generate the heat for the process.

-

Cooling System: May include gas quenching or water cooling for rapid cooling of the workpiece.

-

Control System: Provides precise control over temperature, pressure, and time during the heat treatment process.

Advantages of Using Vacuum Heat Treatment Furnaces:

-

Reduced Oxidation and Decarburization: The absence of oxygen minimizes oxidation and prevents the loss of carbon from the workpiece surface, resulting in improved surface quality and mechanical properties.

-

Cleanliness: The vacuum environment eliminates contamination from atmospheric gases and dust, ensuring a clean and bright finish on treated parts.

-

Uniform Heating: The lack of air convection allows for more uniform heating, reducing distortion and improving consistency.

-

Enhanced Mechanical Properties: Vacuum heat treatment can significantly improve the strength, toughness, and fatigue resistance of materials.

-

Specialized Processes: Vacuum furnaces enable specialized processes like vacuum carburizing and nitriding, which are not possible in conventional furnaces.

Applications of Vacuum Heat Treatment Furnaces:

Vacuum heat treatment furnaces are widely used in various industries, including:

-

Aerospace: Heat treating critical components like turbine blades, landing gear, and engine parts.

-

Automotive: Hardening gears, shafts, and other engine and transmission components.

-

Medical: Manufacturing implants, surgical instruments, and other medical devices.

-

Tooling: Producing high-performance cutting tools, dies, and molds.

-

Electronics: Annealing semiconductor materials and other electronic components.

Types of Vacuum Heat Treatment Furnaces:

-

Single Chamber Furnaces: Basic design with one chamber for both heating and cooling.

-

Double Chamber Furnaces: Separate chambers for heating and cooling, improving efficiency and reducing cycle times.

-

Horizontal and Vertical Furnaces: Different orientations based on workpiece size and shape.

Choosing the Right Vacuum Heat Treatment Furnace:

Consider these factors when selecting a vacuum furnace:

-

Workpiece size and shape

-

Required temperature range

-

Cooling rate requirements

-

Production volume

-

Budget