Industrial Autoclave and Sterilization Manufacturing

Precision-Engineered Solutions for Sterilization and Material Processing

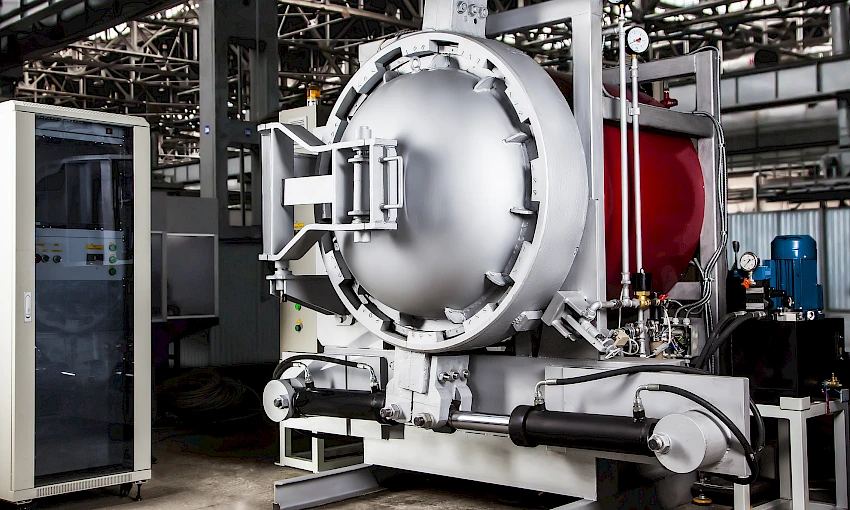

Industrial autoclaves are specialized, sealed vessels that utilize high pressure and temperature for various processes,including sterilization, chemical reactions, and material processing. Sterilization autoclaves, on the other hand, are specifically designed for the sterilization of medical instruments, implants, and other sensitive equipment in medical and laboratory settings.

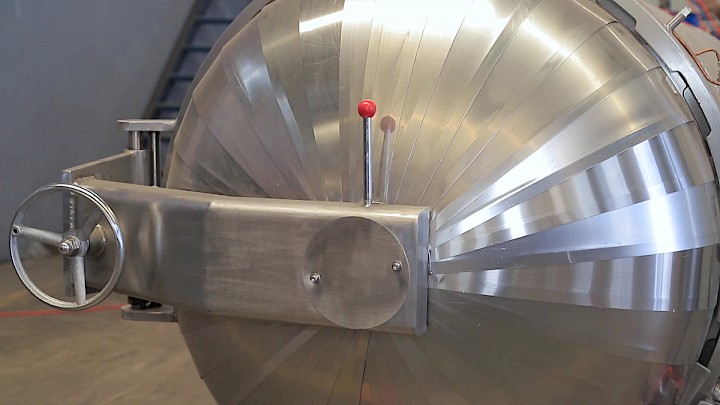

Our autoclave manufacturing process encompasses material selection, design, fabrication, assembly, testing, and quality control. Material selection is crucial for the proper functioning and longevity of the equipment. Therefore, we opt for durable materials such as stainless steel. In the design phase, we work meticulously to ensure that the device performs its functions accurately and is easy to use.

During the manufacturing stage, our experienced personnel utilize modern equipment and technologies to fabricate the autoclaves. In the assembly phase, all components are correctly assembled, and the device is made operational with its complementary equipment. In the testing phase, each autoclave is carefully tested to ensure its proper functioning. The quality control process is also very important to us, and we meticulously carry out the quality control process to ensure that the devices are manufactured in accordance with standards.

What is an Industrial Autoclave?

An industrial autoclave is a specialized chamber designed to process materials under high temperature and pressure. It's a versatile tool commonly used in industries such as healthcare, manufacturing, and research.

Key Features and Functions:

-

Pressurized Environment: Autoclaves create a high-pressure environment to sterilize or process materials effectively.

-

Temperature Control: They can reach temperatures well above boiling point, ensuring thorough sterilization or curing.

-

Vacuum Sealing: Many autoclaves use a vacuum to remove air from the chamber, optimizing the sterilization process.

-

Safety Mechanisms: Equipped with safety features like pressure relief valves and temperature sensors to prevent accidents.

What is a Sterilization Autoclave?

Sterilization autoclaves are special autoclaves used in medical and laboratory settings to eliminate microorganisms. They can utilize different sterilization methods such as steam, chemical, or ozone.

Types of Autoclaves

-

By Application Area: Industrial autoclaves are divided into many types, such as sterilization autoclaves, research autoclaves, food autoclaves, and chemical autoclaves.

-

By Working Principle: Static autoclaves and dynamic autoclaves.

-

By Pressure Level: Low-pressure, medium-pressure, and high-pressure autoclaves.

Autoclave Working Principle

Autoclaves create high-temperature and high-pressure environments using pressurized steam. This environment ensures the destruction of microorganisms and accelerates chemical reactions.

Autoclave Applications

-

Medical: Sterilization of surgical instruments and implants

-

Laboratory: Microbiology studies, culture and media preparation

-

Food: Sterilization to extend the shelf life of food

-

Pharmaceutical: Production of drugs and pharmaceutical products

-

Chemical: Chemical reactions and material processing

Industrial Autoclave Manufacturing

Industrial autoclave manufacturing is a complex and precise engineering discipline. Detailed engineering studies and technical drawings are carried out according to the purpose of use and desired functions of the autoclave. Durable and long-lasting autoclaves are produced using quality materials and advanced technology production techniques.

Sterilization Autoclave Manufacturing

Sterilization autoclaves are specially designed for safe and effective sterilization in medical and laboratory environments.The design of the autoclave is determined according to the sterilization method and the products to be sterilized.

Autoclave Prices

Autoclave prices vary depending on many factors. The most important factors are:

-

Type and capacity of the autoclave

-

Purpose of use and desired functions

-

Materials and production techniques

Key Considerations in Industrial Autoclave Manufacturing

During the manufacturing of industrial autoclaves, many factors must be taken into account to ensure the proper operation and safety of the device. Some important points to consider in manufacturing are:

-

Material Selection: Industrial autoclaves should be made of durable materials as they operate under high temperature and pressure. Materials such as stainless steel ensure the longevity and safety of the device.

-

Design: Industrial autoclaves should be designed correctly. This design ensures that the device performs its functions correctly and is easy to use. In addition, the cleaning and maintenance of the device should also be easy.

-

Pressure and Temperature Control: Since industrial autoclaves operate under high temperature and pressure, the temperature and pressure sensors used in the device should be selected and calibrated correctly. This ensures that the device operates correctly and safely.

-

Insulation: Industrial autoclaves should be properly insulated as they operate under high temperature and pressure.This saves energy and ensures that the device consumes less energy and is less costly.

-

Testing and Quality Control: Industrial autoclaves should be properly tested before and after manufacturing.These tests are done to make sure that the device is working properly. In addition, the quality control process is important and guarantees that the device is manufactured in accordance with standards.

In conclusion, important factors such as material selection, design, pressure and temperature control, insulation, and testing and quality control should be considered during the manufacturing of industrial autoclaves. These factors are vital for the proper operation and safety of the device.

Call to Action:

Contact us for expert guidance on industrial autoclave solutions.

Pressure Vessel

Our company manufactures pressure vessels, pressure tanks, pressure boilers, and other similar pressurized equipment, providing high-quality products to our customers.

As ACES engineers, we are inspired by the revolutionary impact of machines in industrial processes and are dedicated to continuously developing new processes and machines to provide lasting support to our customers. We prioritize customer satisfaction, aiming to make our clients more competitive and to be a partner in their success.

Contact

Phone : +90 536 233 30 76

Email : [email protected]

Address

Address : Ovacık Mah. Mimar Sokak No:10

Başiskele / KOCAELİ / TÜRKİYE