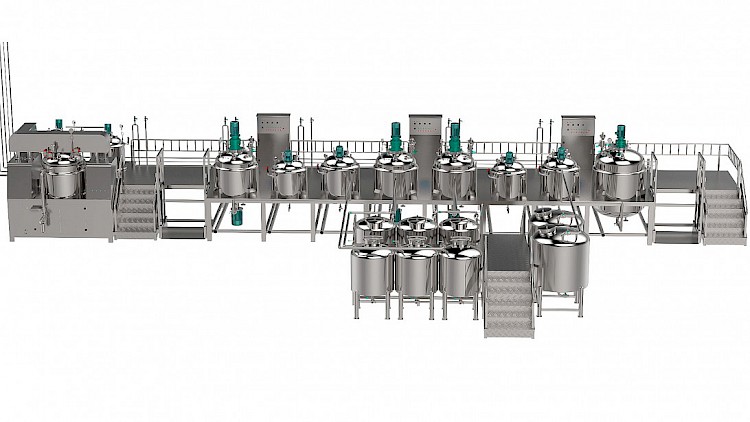

Turnkey Liquid Soap Production Facilities

Aces Process offers comprehensive solutions for liquid soap production, from design to installation. Our state-of-the-art facilities and experienced team ensure that we deliver high-quality, efficient, and hygienic liquid soap production lines.

Key Features of Our Liquid Soap Production Facilities:

-

Capacity: Up to 2500 tons of liquid soap per month

-

Clienst: Grass

-

Automation: Fully automated production systems for maximum efficiency

-

Hygiene: Designed to meet the highest hygiene standards

-

Efficiency: Energy-efficient equipment for reduced operating costs

-

Safety: Compliant with all relevant safety regulations

Benefits to Our Clients:

-

High-quality liquid soap production

-

Reduced production costs

-

Increased efficiency and profitability

-

Fast and reliable production

-

Hygienic production environment

Our Process: Our design director Mahmut Yavuz, oversees every step of the project, from initial design to final commissioning. We ensure that your liquid soap production facility is tailored to your specific needs and meets the highest industry standards.

Liquid Soap Production Facility Costs:

The cost of a liquid soap production facility depends on various factors, including production capacity, equipment, and facility size. To get an accurate quote, please consult our design engineers.

Key Factors Affecting Cost:

-

Facility size and capacity: Larger facilities with higher production capacities will incur higher costs.

-

Equipment and machinery: The type and quality of equipment will impact the overall cost.

-

Automation level: Fully automated systems are generally more expensive than manual or semi-automated systems.

Essential Equipment for Liquid Soap Production:

-

Storage tanks: For storing raw materials

-

Heating and cooling equipment: For temperature control during the production process

-

Homogenizers: To ensure a smooth and consistent product

-

Filling machines: For packaging the finished product

-

Labeling and packaging equipment: For applying labels and packaging the product

-

Industrial mixers: For blending ingredients and creating specific formulations

-

Dosing equipment: For precise measurement and addition of ingredients

Trust Aces Process for Your Liquid Soap Production Needs With our expertise and experience, we can help you build a successful liquid soap production facility. Contact us today for a consultation.