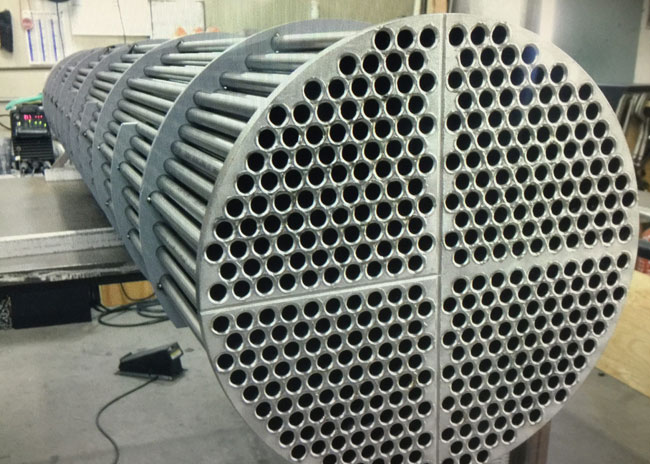

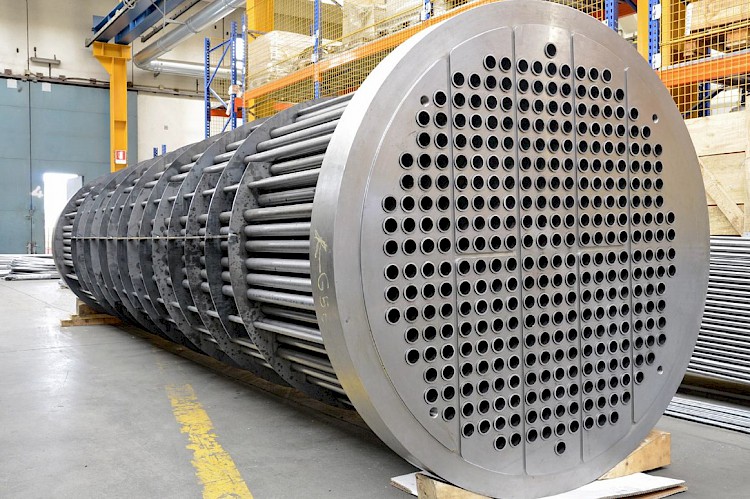

Shell and Tube Heat Exchangers for Petrol Ofisi

Aces Process, a leading manufacturer of heat transfer equipment, has successfully completed a major project for Petrol Ofisi, a prominent player in the Turkish petroleum industry. This project involved the design, manufacturing, and supply of custom shell and tube heat exchangers to meet the specific requirements of Petrol Ofisi's operations.

Project Scope:

-

Design and manufacturing of shell and tube heat exchangers with various capacities and pressure ratings

-

Utilization of high-performance materials such as stainless steel, carbon steel, and nickel alloys

-

Adherence to stringent tolerances and international standards

-

Rigorous testing and inspection of all heat exchangers

Benefits to the Customer:

-

Long-lasting and reliable equipment

-

High efficiency and energy savings

-

Smooth operation and minimal downtime

-

Reduced maintenance costs

A Successful Partnership Aces Process is proud to have partnered with Petrol Ofisi on this significant project. Our commitment to quality and customer satisfaction has resulted in a successful implementation.

Shell and Tube Heat Exchanger Project: 2014-2016 Between 2014 and 2016, Aces Process undertook a major project for Petrol Ofisi's Derince facility, involving the manufacturing and installation of 12 shell and tube heat exchangers. This project showcased our ability to deliver large-scale, complex heat transfer solutions.

Why Choose Aces Process?

-

Customization: Tailored solutions to meet your specific process requirements

-

Quality: Adherence to the highest quality standards and industry regulations

-

Experience: Decades of experience in designing and manufacturing heat transfer equipment

-

Global Reach: Serving clients worldwide in various industries

Explore our shell and tube heat exchanger solutions