Industrial Heat Transfer Solutions: Oil Cooling Exchangers

Oil cooling heat exchangers play a vital role in industrial processes, ensuring optimal operating temperatures for machinery and equipment. Tube-type heat exchangers are a popular and reliable solution in this field.

What are Oil Cooling Heat Exchangers?

Oil cooling heat exchangers are essential components in industrial facilities, designed to maintain optimal operating temperatures for machinery. By preventing excessive oil heating, these exchangers reduce the risk of breakdowns and extend equipment lifespan.

How do Oil Cooling Heat Exchangers Work?

Oil cooling heat exchangers function by transferring heat between the oil and a cooling fluid. The oil flows through tubes within the exchanger, while a cooling fluid (such as water or air) circulates around the tubes. This process dissipates heat, lowering the oil's temperature.

Benefits of Oil Cooling Heat Exchangers:

-

Extended equipment life: Prevents premature wear and tear.

-

Reduced risk of breakdowns: Minimizes downtime and production losses.

-

Energy savings: Optimizes energy consumption.

-

Easy maintenance: Simple to clean and inspect.

Tube-Type Heat Exchangers:

Tube-type heat exchangers are the most commonly used type of oil cooling exchanger. They consist of a housing containing tubes arranged in parallel or cross-flow configurations. The oil flows through the tubes, while the cooling fluid circulates around them.

Advantages of Tube-Type Heat Exchangers:

-

Robust and durable: Can withstand high pressures and temperatures.

-

Easy to clean: Simple maintenance procedures.

-

Available in various capacities: Can be customized to meet specific requirements.

Applications of Oil Cooling Heat Exchangers and Tube-Type Exchangers:

-

Chemical industry: Controls chemical reactions and heat transfer.

-

Food and beverage: Handles temperature changes in liquid products.

-

Oil and gas: Facilitates heat transfer in refinery processes.

Why Choose Aces Process?

-

Custom design expertise: Our engineering team creates tailored solutions to meet your unique needs.

-

High-quality manufacturing: We use premium materials and advanced techniques for reliable performance.

-

Installation and maintenance: Our comprehensive services ensure optimal operation.

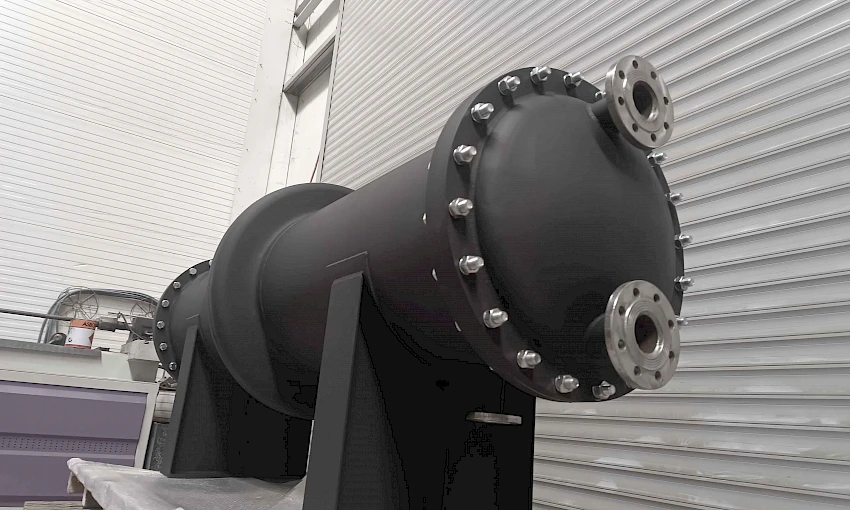

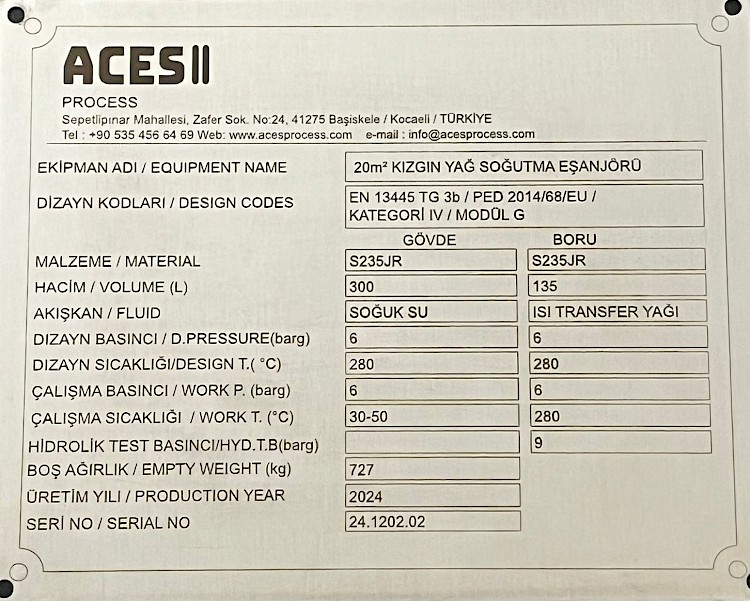

Project: 20 M²

Project Start Date: 11/17/2023

Project End Date: 01/22/2024

Industry: Chemistry

Customer: Frimpeks