Shipment of 4m³ and 12m³ Stainless Steel Mixers and Blenders

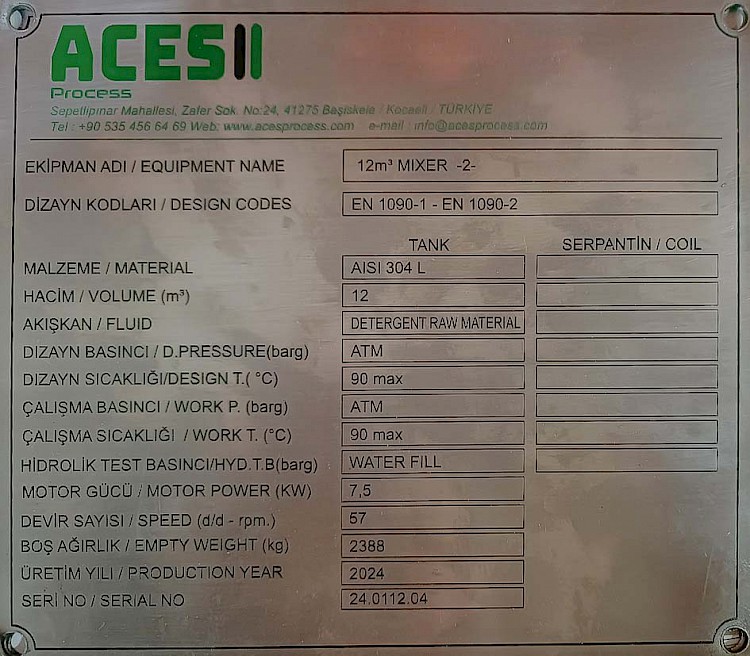

Aces Process has successfully completed a significant project by shipping 2 units of 4m³ and 4 units of 12m³ stainless steel mixers and blenders to a detergent production facility in Uzbekistan. With this project, we aim to significantly increase the efficiency and capacity of the BCG Group's detergent production facility.

Project Details:

-

Product: Stainless Steel Mixers and Blenders

-

2 units of 4m³ capacity mixers

-

4 units of 12m³ capacity blenders

-

-

Facility and Usage Area: Detergent production facility, Uzbekistan

-

Mixer and Blender Features:

-

Durable and robust construction made of AISI 304L stainless steel

-

High capacity and performance

-

Precise mixing and homogenization capabilities

-

Design compliant with EN 1090-1 and EN 1090-2 industrial standards

-

Aces Process Quality:

-

Years of experience and expertise

-

Customized solutions tailored to customer needs

-

Quality and reliability at every stage of the project

Project Specifications:

-

Project: Shipment of Stainless Steel Mixers and Blenders for a Detergent Production Facility

-

Customer: BCG Group

-

Location: Uzbekistan

-

Quantity: 2 units of 4m³ and 4 units of 12m³ Stainless Steel Mixers and Blenders

At Aces Process, we have worked diligently to meet our customers' needs and ensure optimal performance in industrial processes. Our stainless steel mixers and blenders are preferred for their high-quality standards and reliable performance.

For more information or detailed information about our projects, please contact us. Aces Process is pleased to offer you suitable solutions.

What is a industrial blender ?

Industrial Blenders: The Powerhouse of Mixing

Industrial blenders are indispensable tools for businesses demanding efficient and effective mixing of various substances. These robust machines are designed to handle large quantities of materials, making them ideal for production-scale operations across diverse industries.

Key Features of Industrial Blenders:

-

Massive Capacity: Handle substantial volumes of materials.

-

Potent Motors: Ensure thorough and efficient mixing.

-

Adjustable Speed: Precisely control the mixing process to suit different materials.

-

Durability: Built to withstand rigorous use and challenging environments.

-

Customization: Available in various sizes, configurations, and materials to meet specific needs.

Types of Industrial Blenders:

-

Batch Blenders: Ideal for smaller batches or precise control, mixing materials in batches.

-

Continuous Blenders: Ensure a steady flow of blended products, perfect for large-scale production.

-

High-Shear Blenders: Break down clumps, disperse particles, and achieve a homogeneous mixture through a high-shear environment.

-

Vacuum Blenders: Prevent oxidation or contamination by mixing sensitive materials under vacuum conditions.

Benefits of Industrial Blenders:

-

Streamlined Production: Enhance efficiency and increase output.

-

Consistent Quality: Ensure uniform product quality and minimize waste.

-

Versatility: Suitable for a wide range of applications.

-

Cost-Effectiveness: Achieve long-term savings through increased productivity and reduced waste.

Industrial blenders are essential for businesses seeking efficient and effective mixing solutions. By understanding the various types and their key features, you can select the ideal equipment to optimize your production processes and achieve exceptional results.