DIFFERENCES BETWEEN MECHANICAL SEALS AND SOFT SEALS

Dear readers, leak prevention in fluid transfer systems, which form the backbone of industrial processes, is one of the most fundamental and strategic areas of engineering. Controlling fluid flow is an absolute necessity not only for production efficiency but also for environmental sustainability, workplace safety, and operational costs. In this context, packing systems that ensure the leak-tightness of rotating equipment have carved out a unique place for themselves in the engineering world with their technological developments. Although they serve the same basic purpose, they exhibit profound differences in terms of their design philosophies, operating principles, performance characteristics, and application spectrums.

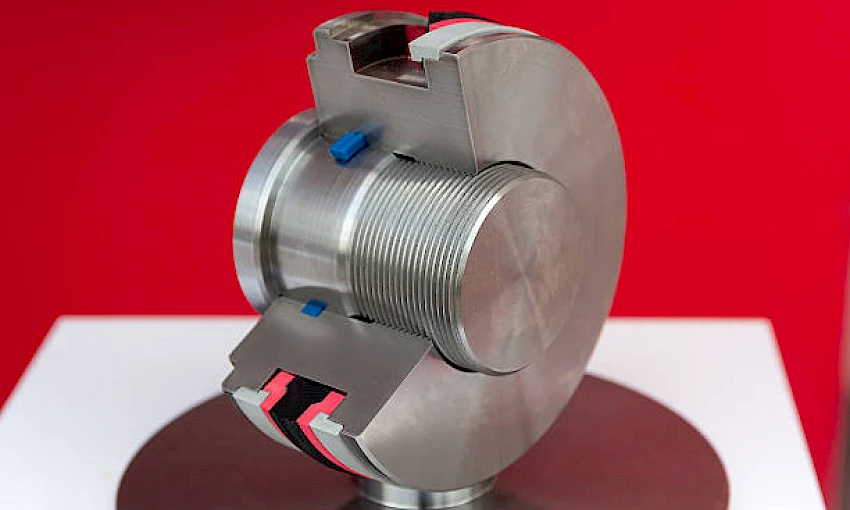

MECHANICAL SEAL

There are two main sealing surfaces that come into contact with each other in an extremely sensitive manner: the “rotating part” that rotates with the shaft and the “fixed part” that is fixed to the body. Between these surfaces, a stable fluid film, typically 1-3 microns thick, is formed. This film minimizes friction between the surfaces while preventing fluid leakage, thanks to the principles of “hydrostatic lift” and “hydrodynamic lubrication.” Spring mechanisms and process pressure continuously maintain the optimum contact force between these surfaces.

-

Near-Zero Leakage: Its most significant advantage is that it provides near-zero leakage even with gas and liquid fluids. This is particularly critical in processes involving hazardous, toxic, valuable, or environmentally regulated fluids.

-

Wide Operating Range: Delivers reliable performance even in the most demanding industrial environments involving high pressure (typically 200 bar and above), high temperatures (up to 400°C and above), and corrosive/abrasive fluids.

-

Low Maintenance and Long Service Life: With the right material selection, precise installation, and under appropriate conditions, mechanical seals offer a long service life and eliminate the need for periodic adjustments or frequent replacement.

-

High Initial Investment Cost: Due to its sophisticated engineering, specialized materials, and complex design, the initial cost is higher than that of soft packing.

-

Precision Installation Requirement: Due to the very tight assembly tolerances, expertise, specialized tools, and an extremely careful installation process are essential. Incorrect installation significantly increases the risk of premature failure.

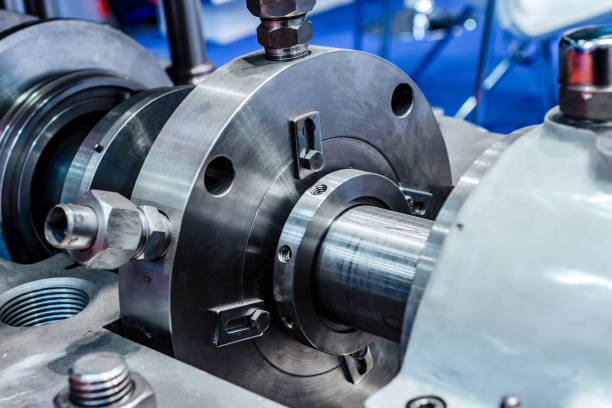

Soft Seal

Soft packing forms a flexible barrier around the shaft or valve body when mechanically compressed within a packing box via a gland nut or flange. This compression ensures sealing by allowing the packing material to expand. The basic principle is to physically block the passage of fluid. In this system, controlled and minimal leakage (in the form of dripping) is usually permitted to maintain optimal sealing; this leakage is a critical factor that helps lubricate the packing material and prevent overheating.

-

Low Initial Cost: Due to their simpler design and production processes compared to mechanical seals, initial costs are significantly lower.

-

Easy Installation and Maintenance: Installation and replacement, if necessary, require relatively less expertise and can be more practical in field conditions. It offers the ability to respond quickly in emergencies.

-

Wide Range of Materials: A wide range of materials is available to suit different chemical compatibility, temperature, and pressure requirements.

-

Mil Alignment Tolerance: It is more tolerant to slight axial or radial misalignments in the mil, which provides an advantage in situations where equipment alignment issues are less critical.

-

Controlled Leakage Requirement: Does not operate on a “zero leakage” principle. It is not suitable if uncontrolled leakage of the process fluid poses an environmental or safety risk.

-

Periodic Maintenance Requirements: The compression setting must be checked periodically, and the packing may need to be replaced due to material wear over time. This increases labor and downtime costs.

-

Shaft Wear Potential: Due to direct friction contact with the shaft, wear or gouging may occur on the shaft during prolonged use, which may result in shaft repair or replacement costs.

-

Higher Friction and Heat Generation: Higher friction coefficients during operation can lead to energy loss and overheating, which can shorten the seal life.

As seen in this analysis, mechanical seals and soft seals have different engineering philosophies and application areas in industrial sealing. The correct seal selection in critical industrial machinery is a strategic engineering decision that directly affects not only operational efficiency but also safety, cost-effectiveness, and environmental compliance.

Writer:

Professor Doctor Mustafa Yaşar

Industrial Design Engineer