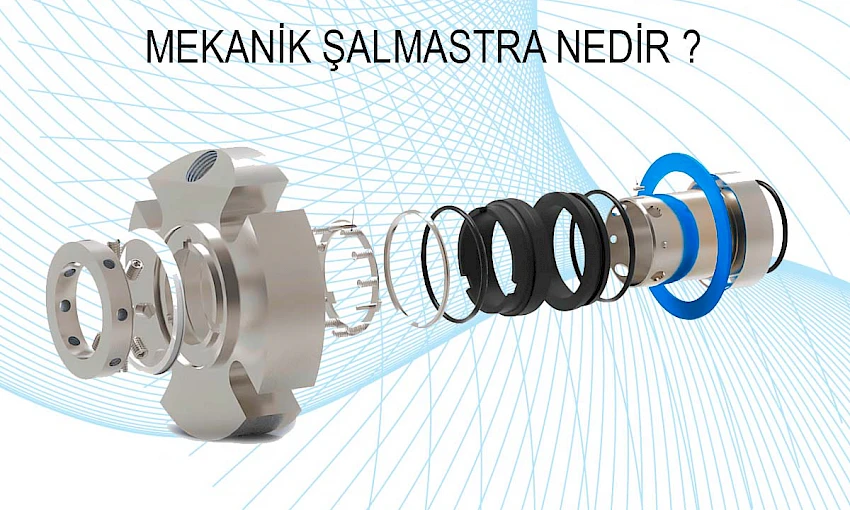

What is a Mechanical Seal?

A mechanical seal is a precision-engineered sealing component designed to prevent fluid leakage between a rotating shaft and a stationary housing (such as a pump casing). Unlike traditional "soft packing," it prevents shaft wear and ensures maximum efficiency with minimum leakage.

It fundamentally consists of two main faces: one rotates with the shaft (rotating element), while the other is fixed to the housing (stationary element). The extremely close contact between these two faces, maintained by a thin fluid film, achieves the sealing.

Definition, Working Principles, and Installation Essentials

In industrial plants, chemical processes, or water treatment systems, the uninterrupted transfer of fluids is of vital importance. The weakest link in these systems is often the shaft sealing. This is where the mechanical seal comes into play—it is the most effective solution modern engineering offers for sealing challenges.

How Does a Mechanical Seal Work?

The operating principle of a mechanical seal is based on hydraulic balance and friction management.

-

Sealing Faces: Two faces—one hard (typically silicon carbide or tungsten carbide) and one softer (such as carbon graphite)—are pressed together by spring force.

-

Fluid Film: During operation, a micro-level fluid film (thinner than a human hair) forms between the faces. This film provides lubrication and dissipates heat generated by friction.

-

Secondary Sealing: Potential leaks through the shaft or the cover are prevented by O-rings or bellows.

Types of Mechanical Seals

Various types are available depending on the application area, chemical composition of the fluid, and pressure values:

-

Single Mechanical Seals: The most common type for standard applications.

-

Double Mechanical Seals: Used for toxic, abrasive, or hazardous fluids, where a "barrier fluid" is introduced between two seals.

-

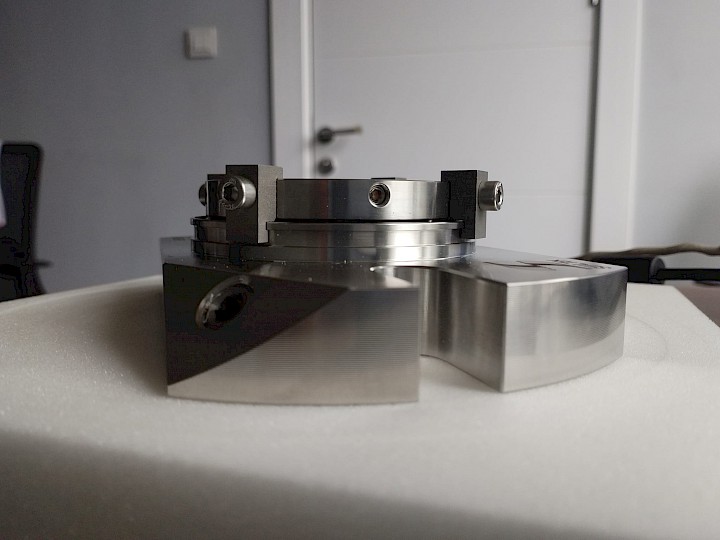

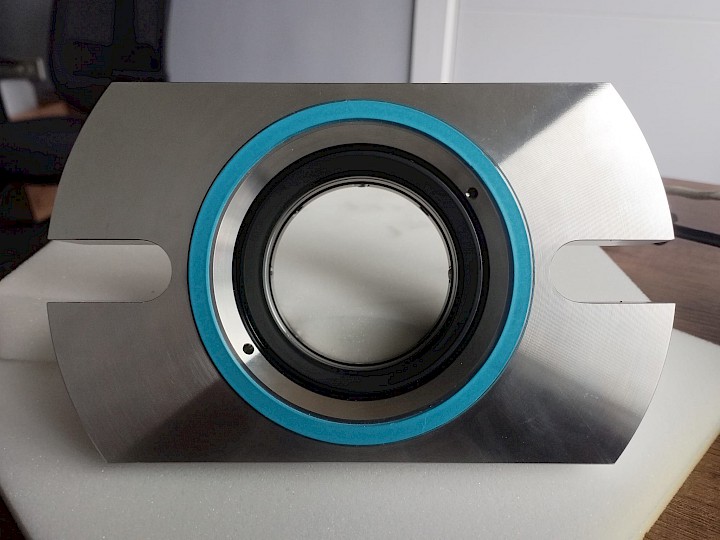

Cartridge Seals: Pre-assembled units that are the easiest to install and require no manual adjustment.

-

Bellows Seals (Metal or Elastomer): Resistant to axial movement and high temperatures.

-

Conical Spring Seals: Simple, robust, and economical solutions.

How to Install a Mechanical Seal?

The lifespan of a mechanical seal is determined 90% by the quality of installation. Incorrect installation can cause a seal to fail within minutes.

-

Preparation: The shaft surface must be smooth, clean, and burr-free. Shaft run-out must be strictly controlled.

-

Cleanliness: Never touch the seal faces with bare hands. Oil or dirt compromises sealing performance. Use alcohol-based cleaners.

-

Lubrication: To facilitate the passage of O-rings, use only manufacturer-recommended lubricants (typically silicone-based or glycerin). Caution: Do not use petroleum-based lubricants for EPDM elastomers!

-

Positioning: Seat the stationary element perfectly perpendicular to the housing. When mounting the rotating element on the shaft, ensure the spring tension is at the correct "working length."

-

Tightening: Tighten bolts crosswise and with equal torque.

How to Measure a Mechanical Seal?

The most critical step in mechanical seal replacement is determining the correct dimensions for a perfect fit. Inaccurate measurements can lead to leaks during installation or render the part completely unusable. To find the correct replacement part accurately, you need these three primary measurements:

-

Shaft Diameter (d1): The exact outer diameter of the shaft (or shaft sleeve) measured with a caliper where the seal sits.

-

Outer Diameter (d3 / d7): The outer diameter of the rotating element or the stationary seat part that fits into the pump housing.

-

Installation Length (L): The total length of the spring-loaded part when compressed, required for ideal sealing during operation.

Why Do Seals Fail?

The greatest enemy of mechanical seals is dry running. Rotating the shaft when there is no liquid inside the pump causes the faces to heat up instantly and crack (thermal shock). Always ensure the pump is primed, vented, and the suction line is open.

Writer:

Professor Doctor Mustafa Yaşar

Industrial Design Engineer