What is a Scrubber?

Scrubber systems are advanced air purification solutions used in industrial facilities to control air pollution and eliminate harmful emissions. These systems, widely employed in various sectors such as chemical, petroleum refineries, metal processing, paper and cellulose industry, wood processing facilities, food, and pharmaceutical industries, effectively filter pollutants such as gases, vapors, dust, and particulates, thereby protecting both the environment and human health.

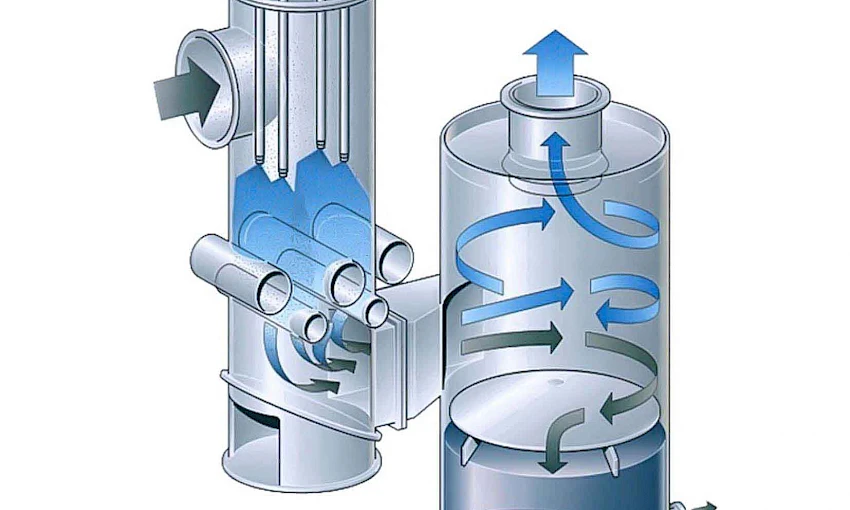

Scrubber units draw in polluted air through a specific system and remove contaminants through absorption, adsorption, chemical reactions, or physical processes. However, since pollutants are transferred into water, the resulting wastewater must also be treated appropriately.

Benefits of Scrubber Systems

-

Improves Air Quality: Filters harmful gases and particulates, ensuring cleaner air.

-

Compliance with Environmental Regulations: Helps industrial facilities meet legal emission limits.

-

Ensures Worker Safety: Protects employees from the harmful effects of hazardous gases and particulates in the workplace.

-

Odor and Smoke Control: Eliminates unwanted odors and smoke generated in factories and facilities.

Types of Scrubbers

1. Wet Scrubber

Wet scrubber systems purify the air by transferring pollutants into a liquid solution. This process generates water vapor, which may require additional treatment. It is particularly effective in removing gases and acidic vapors.

2. Dry Scrubber

Dry scrubber systems remove pollutants using solid or liquid absorbents. Since no water is used, there is no additional water vapor release, and wastewater production is minimized.

3. Electrostatic Scrubber

This system captures and filters airborne pollutants using electrostatic charges. It provides an efficient cleaning process with low energy consumption.

Applications of Scrubber Systems

-

Industrial Facilities: Used to reduce air pollution in the chemical, metal processing, food, and pharmaceutical sectors.

-

Power Plants: Ideal for filtering harmful gases produced from fossil fuel use.

-

Environmental Compliance: Helps meet environmental standards, ensuring legal conformity.

Technical Specifications of Scrubber Systems

-

Capacity: Can be designed based on pollutant concentration and facility needs.

-

Material Selection: Resistant materials such as stainless steel, FRP, or plastic-coated materials are used to withstand acidic gases and high temperatures.

-

Control Systems: Efficient operation is ensured with automatic sensors and PLC systems.

-

Wastewater Treatment: Additional purification systems may be required to separate pollutants from water.

-

Ease of Maintenance: Designs that offer long service life and low operating costs are preferred.

Writer:

Professor Doctor Mustafa Yaşar

Industrial Design Engineer