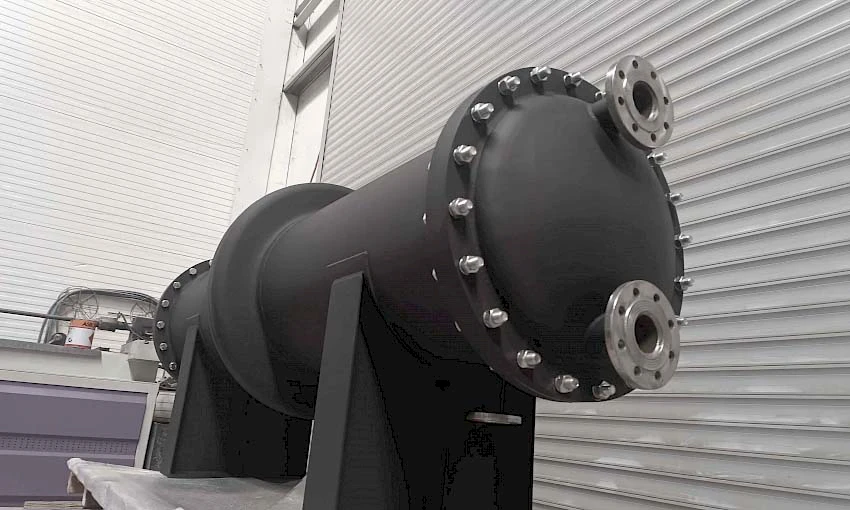

What is a Shell and Tube Heat Exchanger?

Shell and tube heat exchangers are essential components in many industrial processes, enabling efficient heat transfer between two fluids without direct contact or mixing. These exchangers consist of a bundle of tubes enclosed within a larger shell. One fluid flows through the tubes (the tube side), while the other fluid flows around the tubes within the shell (the shell side). Heat is transferred from the hotter fluid to the colder fluid through the tube walls.

Designed to handle fluids with significant pressure differences, shell and tube heat exchangers are commonly used in liquid-liquid and phase-change applications. They are widely employed in various industries, including:

-

Oil refineries

-

Chemical processing plants

-

Power generation

-

HVAC systems

-

Food and beverage processing

The heat transfer typically occurs from the tubes to the shell-side fluid. This method is highly effective for waste heat recovery and optimizing energy efficiency. Shell and tube heat exchangers play a vital role in reducing energy costs and improving efficiency in industrial facilities.

Working Principle of a Shell and Tube Heat Exchanger:

The heat transfer process in a shell and tube heat exchanger relies on three fundamental principles:

-

Thermodynamics: Heat naturally flows from a region of higher temperature to a region of lower temperature.

-

Heat Transfer: Heat is transferred through the tube walls, conducting from the hotter fluid to the colder fluid.

-

Convection: The movement of the fluids within the tubes and shell enhances heat transfer through convection.

Applications of Shell and Tube Heat Exchangers:

-

Power Generation: Heating steam to drive turbines in thermal power plants.

-

Chemical Industry: Heating and cooling fluids in various chemical reactions and processes.

-

Food Industry: Pasteurizing and sterilizing food products.

-

HVAC Systems: Heating and cooling air or water in buildings.

-

Aerospace: Cooling fluids in aircraft engines.

Advantages of Shell and Tube Heat Exchangers:

-

High Efficiency: Provides highly efficient heat transfer between fluids.

-

Versatility: Suitable for a wide range of fluids and temperatures.

-

Durability: Robust construction ensures long service life.

-

Easy Maintenance: Relatively easy to maintain and clean compared to some other heat exchanger types.

Disadvantages of Shell and Tube Heat Exchangers:

-

Fouling Potential: Tubes can become fouled or clogged over time, reducing efficiency. Regular cleaning and maintenance are required.

-

Higher Cost: Can be more expensive than some other heat exchanger types, especially for complex designs or specialized materials.

-

Complex Design: The design and installation can be complex, requiring specialized engineering expertise.

Writer:

Professor Doctor Mustafa Yaşar

Industrial Design Engineer