What is Viscosity?

In its simplest form, viscosity is the resistance a fluid exhibits to flow due to internal friction between its layers. Technically: It is the molecular friction force that arises when one layer of a fluid slides over another.

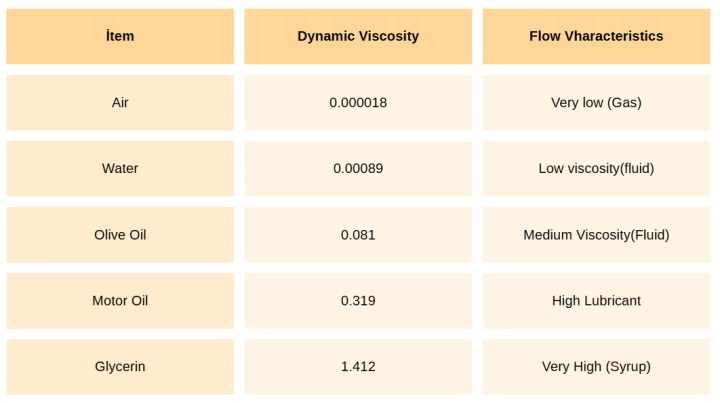

• High Viscosity: Honey, tar, motor oil (Thick, flows slowly).

• Low Viscosity: Water, ethanol, gases (Thin, flows quickly).

Viscosity, one of the most fundamental concepts in fluid dynamics, is a critical parameter that appears everywhere from industrial production to everyday life. Viscosity is the main factor that determines how fast a liquid will flow, how much friction a machine will experience, or how a drug will be absorbed in the body. In this article, we will provide you with all the information you need about viscosity, from details to calculations and formulas, in a professional language.

Types of Viscosity and Mathematical Formulas

It represents the internal resistance of a fluid. It is based on Isaac Newton's flow model between parallel plates.

1. Dynamic (Absolute) Viscosity

Represents the internal resistance of a fluid to flow.

Formula:

τ = μ · (dv/dy)

τ : Shear stress (N/m²)

μ : Dynamic viscosity (Pa·s)

dv/dy : Velocity gradient (s⁻¹)

Units:

SI: Pa·s

CGS: Poise (P), usually centipoise (cP)

1 cP = 0.001 Pa·s

2. Kinematic Viscosity

It is the ratio of dynamic viscosity to fluid density.

Formula:

ν = μ / ρ

ν : Kinematic viscosity (m²/s)

μ : Dynamic viscosity (Pa·s)

ρ : Density (kg/m³)

Units:

SI: m²/s

CGS: Stokes (St), usually centistokes (cSt)

1 cSt = 10⁻⁶ m²/s

Factors Affecting Viscosity

The character of fluids changes depending on environmental conditions. Understanding these changes is essential for managing industrial processes:

1. Temperature: * In liquids: As temperature increases, intermolecular bonds weaken and viscosity decreases.

o In gases: As temperature increases, molecular collision speed increases, viscosity increases.

2. Pressure: Although liquids are generally considered incompressible, under very high pressures, the reduction in voids can cause viscosity to increase slightly.

3. Molecular Structure: Long-chain polymers or complex compounds (e.g., crude oil) tend to exhibit higher viscosity.

How is Viscosity Measured?

The main devices used to measure viscosity in a laboratory setting are as follows:

• Rotational Viscosimeters (Brookfield): Measures the rotational resistance of a spindle in a liquid. Ideal for thick and non-Newtonian liquids.

• Capillary Viscometers: Measures the flow time of a liquid through a narrow tube by gravity. Used for kinematic viscosity.

• Falling Ball Viscometer: Based on the sinking speed of a ball in a liquid.

What Does Viscosity Depend On?

Hello! We can easily understand viscosity, or how much resistance a fluid offers to flow, through the famous consistency differences in our daily lives. The primary factor affecting this is definitely temperature; for example, when you heat honey, it flows like water, but when you put it in the refrigerator, you can't turn the spoon. This is because the heated molecules stop holding each other and become free. Molecular structure also plays a role; if the molecules are long and complex, they become entangled and make flow difficult. From an industrial perspective, especially when it comes to mineral oils or heavy fluids in plants, pressure and the additives used also directly determine this “fluidity balance.” In other words, viscosity is actually the result of the never-ending struggle between the substance and its own internal structure and temperature.

Sectoral Application Areas

• Automotive: Choosing the right oil viscosity is vital to prevent engine wear.

• Food: The consistency of sauces, chocolate, and dairy products determines consumer perception.

• Pharmaceuticals: The dosability of syrups and the flowability of injections depend on viscosity.

Construction: The ability of concrete to settle into molds (workability) is controlled by viscosity.

Viscosity is a mirror that reflects both the physical and chemical identity of a substance. Whether you are performing engineering calculations or optimizing a production process, determining the correct viscosity value while considering temperature and pressure variables will lead you to success.

Writer:

Professor Doctor Mustafa Yaşar

Industrial Design Engineer