Antifreeze Production Facilities

Antifreeze is a liquid used to lower the freezing point of a substance. It is commonly used in car engines, water cooling systems, and various industrial applications.

Aces Process is an engineering and consulting company specializing in the design, installation, and commissioning of antifreeze production facilities. With over 20 years of experience, the company has built antifreeze production facilities in numerous industries.

Aces Process possesses high capabilities and superior engineering expertise in antifreeze production facilities. Our company provides the following services:

-

Design and engineering of antifreeze production facilities

-

Installation and commissioning of antifreeze production facilities

-

Optimization and maintenance of antifreeze production facilities

-

Training and consulting for antifreeze production facilities

As Aces Process, we offer our clients the following advantages:

-

Expert engineering and consulting

-

High-quality workmanship and materials

-

Competitive prices

-

Timely deliveries

Antifreeze production consists of the following basic stages:

-

Raw material preparation

-

Mixing

-

Filtration

-

Storage

ANTIFREEZE PLANT INSTALLATION

Antifreeze plant installation is carried out by Aces Process, which provides high-quality service at every stage, from the design to the assembly of antifreeze production facilities.

Antifreeze Production Facility

Antifreeze production facilities are facilities where antifreeze products are produced to ensure the efficient operation of cooling systems. These facilities are indispensable for improving the performance of liquid cooling systems.

Antifreeze Plant Cost

The cost of antifreeze plants can vary depending on the plant's capacity, technological requirements, and the raw materials to be used. Aces Process offers solutions that suit our customers' budgets.

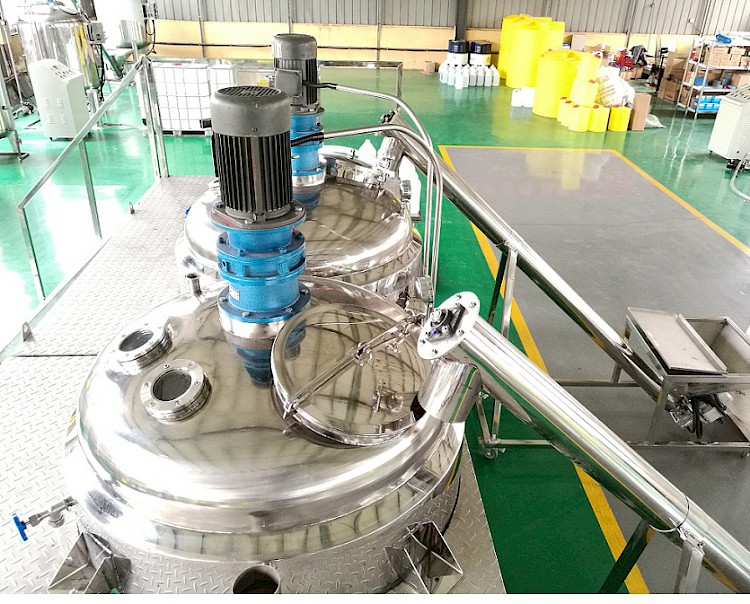

Antifreeze Plant Equipment

The equipment used in antifreeze production facilities has a significant impact on product quality and efficiency. Equipment such as mixers, storage tanks, filling machines, and cooling systems should be carefully selected. Aces Process guides our customers in selecting the best equipment.

Antifreeze Plant Project

The design, construction, and commissioning of antifreeze production facilities is a complex process. Aces Process manages every stage of the project and ensures its smooth completion. It provides expertise to identify and solve any problems that may arise during the project.

Antifreeze Plant Consultancy

Consulting services for antifreeze production facilities can be beneficial at the planning, design, construction, and operation stages of the facility. Aces Process provides customers with best practices and expertise in these processes.

Where is Antifreeze Produced?

Antifreeze is generally produced in specialized antifreeze production facilities. These facilities are designed to ensure the correct formulation and quality of antifreeze.

What is an Antifreeze Plant?

An antifreeze plant is a facility that produces antifreeze to meet the needs of liquid cooling systems. Antifreeze helps prevent freezing and overheating in cooling systems.

How is Antifreeze Produced?

Antifreeze production is carried out by mixing and processing specific chemical components using specially designed production equipment. During this process, the correct concentration and quality of the antifreeze are ensured.

What is the Raw Material for Antifreeze?

The primary raw material for antifreeze is usually chemical components such as ethylene glycol or propylene glycol. These components are mixed with water to create antifreeze products.

How is Antifreeze Made?

Antifreeze production is done by carefully mixing and processing the necessary raw materials. This process is carried out using special production equipment and processes. Antifreeze production must comply with specific quality standards.