What Are Evaporation Systems?

Evaporation systems are mechanical equipment groups that perform concentration or purification processes on an industrial scale, where unwanted water or solvent is evaporated and removed from a liquid substance using thermal energy. This technology, also known in the industry as an evaporator system, holds an indispensable place in the food, chemical, pharmaceutical, wastewater treatment and energy sectors.

In short: Evaporation = The process of heating a liquid to convert excess water into vapor and concentrate the product.

How Does an Evaporation System Work?

The basic working principle of an evaporation system consists of four steps:

-

Feed: The raw liquid product is introduced into the system.

-

Heating: The liquid is brought to its boiling point via steam or hot water.

-

Evaporation: The water or solvent transitions to the vapor phase and is removed from the separation chamber.

-

Concentrate Outlet: The remaining concentrated product is discharged from the system.

This cycle can be configured in a single-stage or multi-stage (multi-effect) structure. In multi-stage systems, the steam generated in the previous stage is used as the heat source for the next stage, dramatically reducing energy consumption.

Types of Evaporation Systems

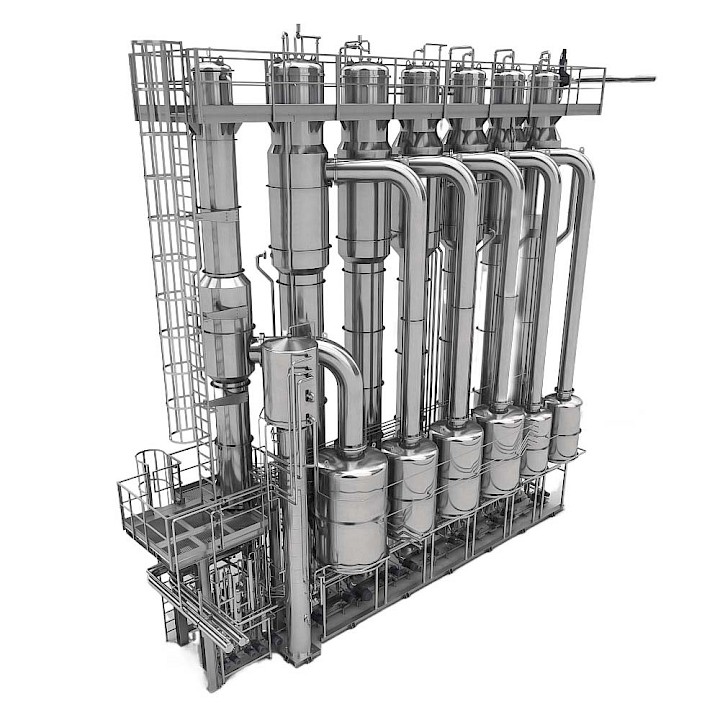

1. Falling Film Evaporators

The most widely used type. The feed liquid is introduced from the top into the tubes and flows downward as a thin film layer. This allows:

-

Heat transfer surface area to be maximized

-

The product to be exposed to high heat for a minimum amount of time

-

Heat-sensitive products (fruit juice, milk, pharmaceutical raw materials) to be processed safely

Applications: Milk concentration, fruit juice production, sugar refining

2. Forced Circulation Evaporators

The liquid is kept in continuous circulation through the heat exchanger with the help of a pump. Ideal for fluids with a risk of crystallization and scaling.

Applications: Salt production, chemical crystallization, wastewater concentration.

3. Short Path / Wiped Film Evaporators

Operating under very low pressure (vacuum), these systems reduce the boiling point as much as possible. Preferred for thermolabile (heat-sensitive) compounds.

Applications: Pharmaceutical active ingredient purification, CBD/essence concentration, high-value chemicals.

4. Mechanical Vapor Recompression Systems (MVR)

The generated steam is fed back into the system as a heat source via a compressor. This technology, which brings energy efficiency to its highest level, can reduce operating costs by up to 70% compared to conventional systems.

Applications: Large-scale dairy facilities, industrial wastewater, chemical plants.

5. Multi-Effect Evaporators

In these systems, which can reach from 2 to 7 stages, each stage utilizes the steam generated in the previous stage. Energy savings increase progressively: a 3-effect system consumes approximately 3 times less steam compared to a single-effect system.

Which Sectors Use Evaporation Systems?

|

Sector / Application |

|---|

|

Food & Beverage: Milk powder, concentrated fruit juice, sugar, molasses. |

|

Chemical: Acid concentration, solvent recovery. |

|

Pharmaceutical: API purification, solvent removal. |

|

Wastewater Treatment : Leachate, industrial waste concentration. |

|

Energy: Boiler feed water preparation, geothermal fluid processing. |

|

Textile: Concentration of dyeing wastewater. |

|

Paper & Coating: Black liquor concentration. |

7 Criteria to Consider When Selecting an Evaporation System

Choosing the right evaporation system directly affects both product quality and operating costs. The following criteria should be taken into consideration:

-

Heat Sensitivity of the Liquid – Low temperature and short contact time are essential for thermolabile products.

-

Viscosity – High-viscosity fluids require forced circulation.

-

Scaling and Crystallization Tendency – Special design is mandatory for products with these characteristics.

-

Target Concentration Ratio – Multi-effect systems should be preferred for high concentration requirements.

-

Capacity (kg/h or tons/day) – System size and number of stages are determined according to capacity.

-

Energy Source and Cost – MVR systems are ideal for facilities with high energy costs.

-

Cleaning and Hygiene Requirements – CIP (Clean-In-Place) compatible design is mandatory for the food and pharmaceutical sectors.

Advantages of Evaporation Systems

Why choose evaporation?

-

High energy efficiency: Energy consumption is minimized, especially in MVR and multi-stage systems.

-

Preservation of product quality: Low-temperature and short processes preserve nutritional values and compound integrity.

-

Continuous and automated operation: Modern systems can be monitored 24/7 with PLC/SCADA integration.

-

Wide capacity range: Scalable from small laboratory scale to hundreds of tons per day capacity.

-

Environmental compliance: Reduces the volume of wastewater, lowering disposal costs and contributing to the zero liquid discharge (ZLD) target.

Energy Efficiency in Evaporation Systems

Energy costs constitute a significant portion of total production costs in industrial facilities. Evaporation systems offer a critical optimization opportunity at this point:

-

Single-effect system: Consumes ~1 ton of steam to evaporate 1 ton of water.

-

3-effect system: Consumes ~0.33 tons of steam to evaporate 1 ton of water.

-

MVR system: Consumes only 5–15 kWh of electricity to evaporate 1 ton of water.

This difference can mean savings of millions in annual energy bills.

Frequently Asked Questions (FAQ)

What is the difference between an evaporation system and distillation?

Evaporation generally removes water or solvent to concentrate a substance; recovering the vapor is not the primary objective. In distillation, the evaporated component is cooled and recovered, with separation being the primary focus.

What should the maintenance interval be for evaporation systems?

While it varies depending on the system and the product being processed, the general rule is: weekly CIP, monthly mechanical inspection, and annual comprehensive maintenance. These intervals should be shortened for processes prone to scaling.

How long does evaporation system installation take?

Small systems (< 500 kg/h) can typically be commissioned within 4–8 weeks, medium-scale systems within 3–6 months, and large industrial facilities within 6–18 months.

What is the minimum capacity?

For pilot and R&D scale systems, capacity can start from a few kilograms per hour. For industrial systems, a capacity scale above 100 kg/h is generally preferred.

Increase Your Efficiency with the Right Evaporation System

To determine the most suitable evaporation system for your project, perform capacity calculations, or optimize your existing system,contact our expert team.You can benefit from our free preliminary assessment and technical consultancy service.