Turnkey Lime Production Plant Installation

At ACES Process, we provide turnkey lime production plant installations — from engineering design to commissioning. Our expertise covers the entire lime manufacturing process, integrating all systems from raw material handling to automation within a single, efficient, and reliable setup.

We design and deliver modern lime factories that combine high efficiency, low emissions, and process automation, ensuring sustainability and long-term performance for industrial clients.

How Lime is Produced

Lime is obtained by calcining high-purity limestone (CaCO₃) at elevated temperatures. During this process, carbon dioxide (CO₂) is released, and quicklime (calcium oxide – CaO) is produced. When quicklime reacts with water in a controlled manner, it forms hydrated lime (calcium hydroxide – Ca(OH)₂), which is used in various industrial and environmental applications.

Main stages of lime production:

-

Raw Material Preparation: Crushing, screening, and feeding of limestone.

-

Calcination: Thermal decomposition in lime kilns at 900–1100°C.

-

Cooling & Dust Removal: Controlled cooling and separation of fine particles.

-

Storage & Packaging: Silo systems, big bag and automatic bagging units.

-

(Optional) Hydration: Quicklime is converted into hydrated lime.

Engineering, Feasibility & Project Management

A successful lime plant investment starts with detailed engineering and planning.

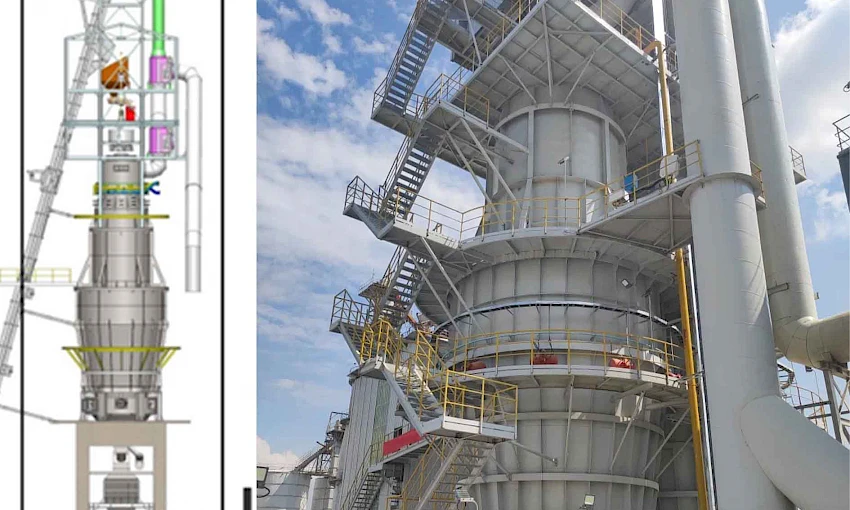

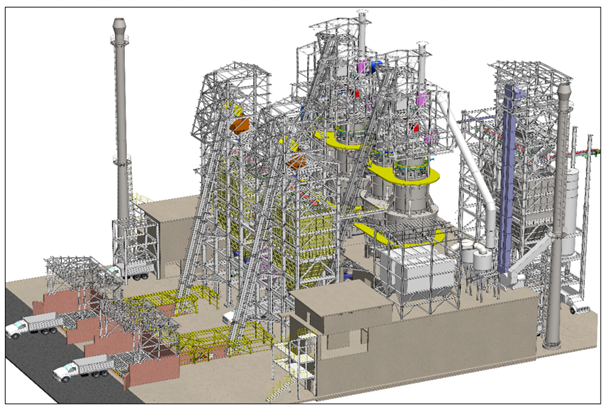

We carry out process simulations, feasibility analyses, and 3D layout design to ensure smooth operation, optimum capacity, and minimal energy loss.

Project Flow & Layout Design

-

Optimization of all stages: crushing, kiln feeding, calcination, cooling, and packaging.

-

Smart plant layouts designed with CAD & 3D modeling.

-

Efficient use of space, safe maintenance routes, and minimized energy consumption.

Project Scheduling with Gantt Chart

-

Step-by-step time planning for construction, mechanical, electrical, and automation works.

-

Clear milestones and critical path tracking.

-

Preventive planning to eliminate project delays and budget overruns.

Capacity & Efficiency Analysis

-

Calculation of annual and hourly production targets.

-

Evaluation of kiln capacity, raw material input, energy and emission values.

-

Energy-saving options through modern kiln design and automation control.

-

Modular expansion options for future capacity increases.

Why Lime is Vital for the Iron & Steel Industry

In iron and steel production, lime is a key input that ensures high-quality metal output.

It acts as a fluxing agent, binding unwanted oxides and forming slag that can easily be removed from molten metal.

Additionally, lime contributes to gas purification, wastewater treatment, and furnace desulfurization.

ACES Process designs high-capacity lime plants tailored to the needs of the steel industry, featuring:

-

High-temperature resistant kiln materials

-

Energy-efficient combustion and air systems

-

Full compliance with ATEX, CE, and ISO standards

-

Advanced dust collection and emission control systems

Core Components of a Lime Factory

A) Main Production Units

-

Raw Material Preparation: Limestone crushers, screens, and feeders.

-

Calcination Kilns:

-

Shaft kilns – energy-efficient, suitable for small to medium capacities.

-

Rotary kilns – high-capacity, continuous operation for industrial production.

-

-

Cooling & Classification Units: Hot lime cooling and impurity removal.

-

Hydration Systems: For converting CaO into Ca(OH)₂ with precise moisture control.

-

Conveying Systems: Screw conveyors, belt conveyors, and bucket elevators.

-

Storage & Packaging: Silos, big bag units, and automated packing machines.

B) Auxiliary Systems

-

Dust Collection & Filtration:

Cyclone separators, bag filters, and stack filters ensure full compliance with environmental regulations (EIA & emission standards). -

Automation & Control Panels:

Process parameters such as temperature, feed rate, and kiln speed are controlled via PLC/SCADA for consistent product quality. -

Energy & Fuel Systems:

Kiln fuel options include natural gas, coal, RDF, and fuel oil.

Waste heat recovery systems further enhance energy efficiency.

Important Lime Factories in The World

ACES Process Advantage

-

Complete turnkey lime factory installations

-

Customized process design based on raw material and target capacity

-

Energy-efficient and eco-friendly systems

-

Automation and digital control integration

-

Engineering and after-sales support from a single source

At ACES Process, we transform limestone into industrial value — building the next generation of smart, efficient, and sustainable lime production plants.