Lubricant Oil Production Plants

Turnkey Lubricant Oil Production Plants are advanced manufacturing facilities where base oils derived from crude oil are precisely blended with chemical additives in controlled ratios to produce industrial lubricants that reduce friction and prevent wear.

Turnkey Lubricant Oil Production Plant Installation Aces Process

In the industrial world, the service life of machinery is directly linked to the quality of the lubricant used, and lubricant quality is directly dependent on the technological infrastructure of the production facility. Today, establishing a lubricant oil production plant is far more than simply installing tanks side by side. Increasing global standards, energy efficiency requirements, and the need for precise formulations demand a strong engineering vision during plant design and installation.

In this guide, we examine the anatomy of a high-performance lubricant oil production plant and the best practices that define industry standards.

Aces Process Lubricant Oil Plant Standards

-

We deliver custom-engineered designs fully aligned with the investor’s operational structure and capacity targets.

-

We guarantee high durability and long service life across all system components.

-

We ensure maximum plant safety through certified raw material selection and advanced workmanship quality.

-

We implement jacketed reactor designs and integrated cooling coil solutions that maximize thermal efficiency.

-

We provide comprehensive technical documentation, maintenance protocols, and operation manuals to ensure uninterrupted operation.

-

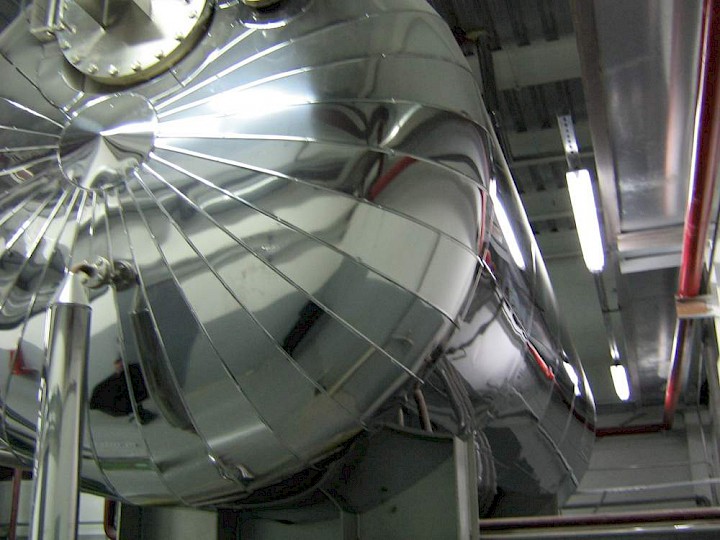

We construct ergonomic, modular systems with high insulation standards to minimize heat loss.

-

We integrate inverter-supported precision speed control systems that can be optimized according to product characteristics.

-

We install high-precision load cell weighing systems that provide milligram-level data accuracy from raw material intake to final product output.

-

We enable error-free production through fully automated PLC and SCADA control panels with user-friendly interfaces.

-

We utilize internationally certified Ex-proof equipment and high-protection-class IP motor technologies for hazardous areas.

-

We develop blade and mixing systems specifically designed for different viscosity and density values, ensuring 100% homogeneous blending.

-

We apply mirror-finish polishing to prevent product adhesion and use corrosion-resistant specialty coating standards.

-

We offer certified reactor solutions tested under high-pressure and vacuum conditions suitable for extreme process environments.

-

We provide complete turnkey installation services covering project engineering, design, manufacturing, and on-site assembly.

Lubricant Oil Production Plant Technologies

We seamlessly integrate PLC and SCADA-based smart automation systems into our lubricant oil production plants. This innovative infrastructure ensures full process traceability while optimizing resource utilization and directly contributing to sustainable production goals.

-

PLC & SCADA-Supported Automation: Fully automated control panel integration where all formulations are digitally managed, minimizing human error.

-

Ex-Proof Standards: Use of internationally certified IP motors and safety equipment in facilities handling flammable and combustible components.

-

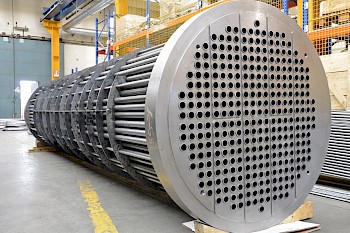

Thermal Efficiency: Maximum heat transfer with minimum energy consumption through heating and cooling coils or jacketed reactors.

-

High-Precision Load Cell Systems: Milligram-level monitoring at every stage, from raw material input to finished product output.

Lubricant Oil Production Plant Process Flow

Base Oil Storage & Warehousing → Raw Material Transfer & Filtration → Preheating & Reactor Feeding → Precision Additive Dosing → High-Speed Homogeneous Mixing → Viscosity & Quality Control Tests → Product Cooling & Heat Recovery → Fine Filtration → Resting & Storage Tanks → Automatic Filling & Packaging Line → Final Product

The lubricant oil production process flow engineered by Aces Process is designed with a strong focus on high precision and automation integration at every stage—from raw base oil reception to the final packaging line. At the core of the process, jacketed reactors maintain thermal stability while base oils and specific chemical additives are blended using high-speed mixers to form a microscopically homogeneous lubricating film.

High-precision load cell weighing systems and PLC/SCADA-based recipe management ensure viscosity stability throughout the process, while in-line filtration and cooling units guarantee full compliance with international API and SAE standards. In turnkey lubricant oil plant projects, Aces Process designs a sustainable industrial ecosystem that delivers minimum energy consumption and maximum operational efficiency.

Machinery Required for Lubricant Oil Production

At Aces Process, we design and manufacture all turnkey solutions required for a lubricant oil production plant in-house. From engineering and design to manufacturing, we manage every detail—delivering the complete machinery line, from high-performance reactors to complex storage solutions, in accordance with international quality standards and tailored to your plant’s capacity requirements.

-

Blending Reactors

-

Product Storage Tanks

-

Dosing Units

-

Automatic PLC & SCADA Control Panels

-

Heat Exchangers

-

Industrial Mixers

-

Filtration Units

-

Raw Material Transfer Pumps

-

Automatic Filling Machines

-

Steam Boilers

Infrastructure Costs for Establishing a Lubricant Oil Production Plant

Key cost items to consider during investment planning include:

-

Land and construction

-

Machinery and equipment

-

Storage units

-

Filling and packaging lines

-

Utility and auxiliary facilities

Operating expenses typically include

-

Raw material supply

-

Energy and utilities

-

Labor and management

-

Logistics and transportation

-

Maintenance and repairs

References & Standards

-

ISO 9001:2015

-

ISO 14001

-

ISO 45001

-

TS 13369

-

API

-

CE

-

Ex-proof

For turnkey lubricant oil production plants that set industry standards, contact our sales team.

Partner with ACES Process for Your Lubricant Production Needs

At ACES Process, we offer comprehensive, tailored solutions to meet the evolving needs of the lubricant industry. Contact us today to explore our expertise in lubricant plant design, construction, and optimization.

📩 Get in touch with us today to discuss your project requirements and discover the best solutions for your lubricant production facility.